- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

TONY

-

Voltage:

-

380V/50HZ or customized

-

Dimension(L*W*H):

-

1850*1050*1800MM

-

Motor Power (Kw):

-

110kw

-

Power (kW):

-

110+1.5+0.37kw

-

Weight (KG):

-

6100 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

wood pellet machine/alfalfa pellet mill

-

Type of pellet machine:

-

roller turning ring die pellet machine

-

Application:

-

Biomass fuel pellets producing, power generation plant

-

Material of roller and die:

-

Alloy steel stainless steel

-

Lubrication:

-

Independent Automatic Lubrication

-

Raw Materials:

-

wood chips, sawdust, timber, trunks .ets wood wastes

-

Driving Method:

-

Big Gear transmission pellet mill

-

Diameter of pellet:

-

4-12mm

-

Motor:

-

AC electric motor/ disel engine/tractor

Quick Details

-

Pellet Diameter (mm):

-

6 - 12

-

Output (kg/h):

-

1500 - 2000 kg/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

TONY

-

Voltage:

-

380V/50HZ or customized

-

Dimension(L*W*H):

-

1850*1050*1800MM

-

Motor Power (Kw):

-

110kw

-

Power (kW):

-

110+1.5+0.37kw

-

Weight (KG):

-

6100 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

wood pellet machine/alfalfa pellet mill

-

Type of pellet machine:

-

roller turning ring die pellet machine

-

Application:

-

Biomass fuel pellets producing, power generation plant

-

Material of roller and die:

-

Alloy steel stainless steel

-

Lubrication:

-

Independent Automatic Lubrication

-

Raw Materials:

-

wood chips, sawdust, timber, trunks .ets wood wastes

-

Driving Method:

-

Big Gear transmission pellet mill

-

Diameter of pellet:

-

4-12mm

-

Motor:

-

AC electric motor/ disel engine/tractor

|

Biomass Ring Die Alfalfa Pellet Mill/Wood Pellet Machine

|

|

|

|

|||

|

(TYJ450 TYJ550 TYJ680 TYJ860 TYJ980)

|

|

|

|

|||

|

It's mainly used to produce biomass fuel pellets from the

raw materials

of

wood sawdust, wood

waste

and straws, etc. such as woodchips(palm, pine white pine, mahogany, pinus sylvestris, rubber tree), bamboo shavings, rice husk, seeds shells, peanut shells, halm, pennisetum, wheat straw, corn stalk, cotton stalks, alfalfa grass, bagrass, palm fiber, waste paper, non-physical material.

|

|

|

|

|||

|

Testing and Clients' Site For Pellet Machine

|

|

|

|

|||

|

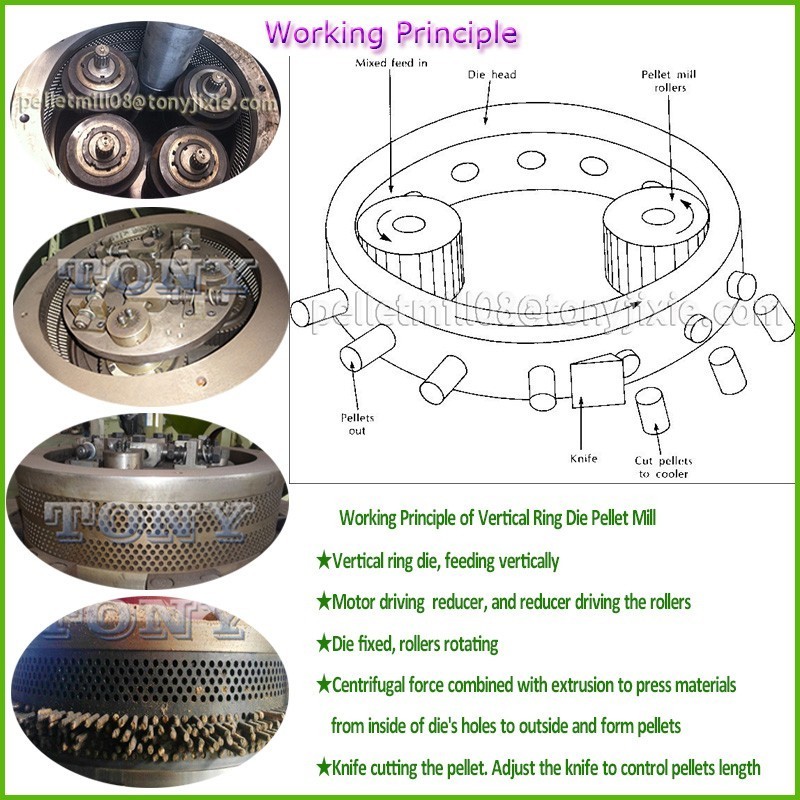

Working Principle of Pellet Machine

|

|

|

|

|||

|

Main Features of Vertical Pellet Machine

|

|

|

|

|||

|

Self -lubrication system

|

A.Spindle automatic lubricatin system

B.Roller automatic lubricatin system: keep the pellet machine in maintenance for 24hours. |

|

|

|||

|

Output of pellet mill machine

|

Can reach the expected output in our technical parameter.

|

|

|

|||

|

Working Life of spare parts

|

Working life of our dies is 2500-3000 h, much longer than others’.

|

|

|

|||

|

Number of Our Ring Die holes

|

Our ring die has 5 rows of holes, much more than others’.

|

|

|

|||

|

Driving Method

|

Two types: big gear and reducer

|

|

|

|||

|

Forged Main Shaft

|

Our main shaft is forged, not casted. As well known, there is no air bubble in forging process, so it is hard to be broken.

|

|

|

|||

|

Requirements for raw materials

|

|

|

||

|

Size

|

Less than 5 mm

|

All the raw materials must be crushed into sawdust before going

to wood pellet machine.If not, you may need a wood chipper, wood crusher. |

||

|

Moisture

|

10-15%

|

Better for pelletizing high quality pellets,

|

||

|

Final Pellets

|

For burning

|

Ø6mm/8mm: household stove burning;

Ø8mm-18mm: Industrial using

Energy Level: 5kwh/kg, Compared to Oil: 1 lty oil = 2kg wood pellets

|

||

|

Example: TYJ550 Packaging

|

|

|

|

Size

|

1850(L) * 1050 (W) * 1800 (D) mm

|

|

|

Weight

|

4T

|

|

|

Packaging Details

|

The normal package is wooden box or iron case.

We will use pe film for packing or pack it according to customers special request.

|

|

|

Payment Terms & Conditions

|

|

|

|

|||

|

Price Term

|

FOB Qingdao Port, China

|

|

|

|||

|

Payment

|

35% T/T in advance, 65% balance payment after inspection before shipping

|

|

|

|||

|

Delivery Time

|

In 30 days after receiving the confirmed order and down payment.

|

|

|

|||

|

Warranty

|

12 months for each unit after receiving except wear parts.

|

|

|

|||

|

Service Abroad

|

Engineers are available for oversea technical services based on mutual agreement. The Seller send technicians to the buyer for technical assistance including supervising installation, commissioning, testing and training workers of the Buyer, maintenance and dismantlement of seller’s products

|

|

|

|||

|

TONY

--- Professional Manufacturer of Pellet Machines

|

|

|

|

Brief Intro

|

Owns a professional team in

researching

,

designing

,

manufacturing

,

trading

,

installing

instructing

and

serving

on pelleting equipments.

|

|

|

Main Products

|

Biomass wood pellet line, various pellet mill/machines, grinding and crushing equipments, drying equipments, cooler, screening, conveying products and so on.

|

|

|

Successful Export Experiences

|

“TONY” machines with good reputation have been exported to lots of

Europe, South America, Southeast Asia countries, and set agents in Brasil ,Canada, Germany, America, South Africa, Australia, India,Vetnam, Malaysia and so on countries.

|

|

|

Tony Main Products

|

|

|

|

|||

|

Ring Die Pellet Machine

|

Ring Die Feed Pellet machine

|

Electric Engine Pellet Machine

|

Hammer Mill

|

|||

|

Flat Die Pellet Machine

|

Flat Die Feed Pellet Machine

|

Diesel Engine Pellet Machine

|

Wood Crusher

|

|||

|

Biomass Pellet Machine

|

Pellet Production Line

|

Tractor Engine Pellet Machine

|

Sawdust Machine

|

|||

|

Wood Chipper

|

Drum Dryer

|

Packing Machine

|

Straw Chopper

|

|||

The advantages of buying equipments in our company are:

1.

a full range of design, construction, equipment supply, construction, installation supervision and commissioning, staff training;

2.

license for the design, construction, installation, wiring, and other works;

3.

full certification of equipment;

4.

officially registered trade mark;

5.

full warranty, post warranty and service;

6.

warranty on all equipment - 13 months;

7.

ratio price-quality-assurance;

8.

vast project experience. we have established and put into operation so many of pellet plant productivity on the finished product from 0.5 to 20 t / h in Malaysia, Thailand, Vietnam, Germany, France, Bulgaria, Serbia, Romania, Korea, Australia etc;

9.

large stock of finished equipment and spare parts;

10.

all equipment of our production, equipped with electric motors and gearboxes, that made in big company

Questions asked Frequently

Q: What is a pellet mill/pellet machine?

A: A pellet mill/pellet machine is a machine that takes raw materials and shapes it into pellet form for multiple uses.

Q: What kind of materials can be pelletized?

A: Materials such as wood wastes, saw dust, corn cobs/stover/stalks, straw, switch grass, other grasses, distillers grain, paper, etc. Basically, most Biomass materials that can be ground down to sawdust form can be pelletized.

Q: What are pellets used for?

A: Pellets are used mainly for heating, animal feed, and animal bedding. Many other applications may apply.

Q: What size does my material need to be, to run through the pellet mill?

A: All materials must be

5mm or less

.

Q: What size pellets can I make?

A: We have dies sizes from

4mm-12mm

, depending on the machine or your raw materials.

Q: Do you ship worldwide?

A: Yes. We have sent machines to Canada, Europe, Asia, Southeast Asia, Africa, South America, Ireland and Australia.

Q: If I purchase a pellet mill, will you show me how to make pellets?

A: Yes, we do. We will instruct you how to use it via video or phone or engineer avaliable abroad if you need.

|

Best quotation offered if telling me the following information in your inquiry

|

|

|

|

1

|

The capacity you plan to manufacture

|

|

|

2

|

Your raw material, its size and moisture

|

|

|

3

|

The pellet size you want to get

|

|

|

4

|

The pellet application, for burning or feeding animals?

|

|

|

5

|

The voltage required in your country

|

|

Miss Amy Zhang

(Business Development Manager)

Whatsapp:+86-15853148288

Skype:tonypelletmill_01

Email:pelletmill01 at tonyjixie.com

----------------------------------------------------------------------------------------------------------------------------------------

Pellet Mill, Pellet Making Line , Grinding Equipment, Crushing Equipment, Drying Equipment!