- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220v,50hz

-

Dimension(L*W*H):

-

1150*1150*1300mm

-

Weight:

-

200 KG

-

Product name:

-

Sieve Shaker Manufacturer/Flour Vibrating Filter Machine

-

Keyword:

-

Vibrating Filter Machine

-

Material:

-

Stainless Steel 304

-

Color:

-

customized

-

screen:

-

2-500mesh

-

Layer(s):

-

3 layer

-

Function:

-

vibrating screen filter

-

Diameter:

-

300-2000

-

Mesh size:

-

2-500

-

power:

-

0.75kw

Quick Details

-

Type:

-

Circular

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ormech

-

Voltage:

-

220v,50hz

-

Dimension(L*W*H):

-

1150*1150*1300mm

-

Weight:

-

200 KG

-

Product name:

-

Sieve Shaker Manufacturer/Flour Vibrating Filter Machine

-

Keyword:

-

Vibrating Filter Machine

-

Material:

-

Stainless Steel 304

-

Color:

-

customized

-

screen:

-

2-500mesh

-

Layer(s):

-

3 layer

-

Function:

-

vibrating screen filter

-

Diameter:

-

300-2000

-

Mesh size:

-

2-500

-

power:

-

0.75kw

Product Description

High Efficiency Sieve Shaker Manufacturer/Flour Vibrating Filter Machine

Automatic Sieving Machine is a general vibration screening, filtration equipment, It has good application in the powder, granular and liquid materials. Our XZS series of rotary vibrating screen is based on many years production experience and combined customers’ practical situation, and learn from Japan, Germany and other countries similar products and technical characteristics, We successfully developed new design of high efficient screening equipment.

Technical Parameters:

|

Model |

S49-400 |

S49-600 |

S49-800 |

S49-1000 |

S49-1200 |

S49-1500 |

S49-1800 |

S49-2000 |

||

|

Effective screening diameter (mm) |

Φ340 |

Φ540 |

Φ730 |

Φ900 |

Φ1100 |

Φ1400 |

Φ1700 |

Φ1886 |

||

|

Effective screening area (m2) |

0.0907 |

0.2289 |

0.4183 |

0.6359 |

0.9499 |

1.5386 |

2.2687 |

2.7922 |

||

|

Screen Size |

2 ~ 500 mesh / inch |

|||||||||

|

Layer |

1-5 |

1-5 |

1-5 |

1-5 |

1-5 |

1-5 |

1-3 |

1-3 |

||

|

Power |

Vibration motor |

0.18 |

0.25 |

0.55 |

1.1 |

1.1 |

1.5 |

4.0 |

4.0 |

|

|

General Motors |

- |

0.75 |

1.1 |

1.5 |

1.5 |

2.2 |

3.0 |

3.0 |

||

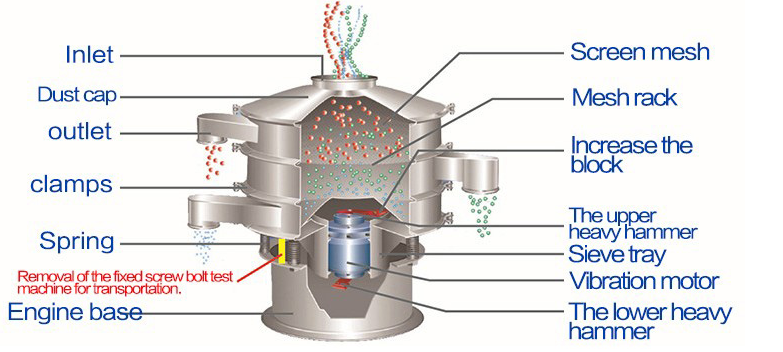

1:Product Features:

1. High efficiency,refined design,duration ,any powders and mucilage are suitable for using.

2. Easily to replace the screen, simple operation and convenient washing.

3. Never jam the hole meshwork, no powder flying, filter size of the powder between 1.25 micro meter to 5 mm.

4. Discharge the impurity and coarse materials automatically and operates continuously.

5. Unique screen frame design, long duration of screen, only 3-5minutes to replace the screen.

6. Small volume, move easily.

7. The highest layers of the screen are about 5 layers. But 3 lagers are suggested.

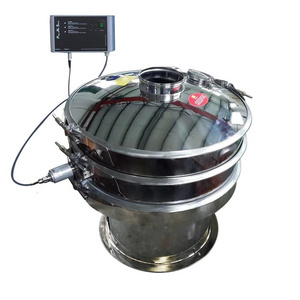

2.Product Shows:

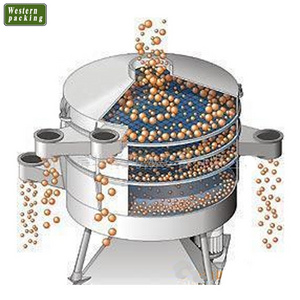

Advantages For the Spin Vibrating Screen:

More advantages for the roy spin vibrating screen: Long running track for the material, the screen surface with high use ratio, high precision screening(up to 95%).

By adjusting the upper and lower hummers phase angle, can change the material’s running track and the speed of the spread, and the the material can maintain long term circular motion.

Through adjusting the upper and lower hammers, The material can be fine sieve, probing screening and other screening operations.

High efficient accurate screening:

1:Fully enclosed structure, no powder flying, no liquid leak,

2:The mesh is not blocked,

3:Discharge the impurity and coarse materials automatically,

4:Without stock material in the machine, Frame structure without dead ends, increased screen area.

4.Application Area:

Widely used for granular,powder and mucus materials.

Chemical industry : resin, paint, industrial chemicals, cosmetics, paint, powder etc.

Food industry: sugar, starch, salt, rice flour, milk powder, milk, egg, soy sauce, fruit juice etc.

Metals, Metallurgy Mining: aluminum, lead powder, copper powder, ore, alloy powder, welding powder, manganese dioxide, copper powder, electric magnetic materials, abrasive powder, refractory materials, kaolin, limestone, alumina, heavy carbonate calcium, quartz sand etc.

Pollution treatment: waste oil, waste water, dyeing wastewater, additives, such as activated carbon etc.