- Product Details

- {{item.text}}

Quick Details

-

Power:

-

20-25KW

-

Weight:

-

1200 KG

-

Product Name:

-

Rice MIlling Machine

-

Rated Capacity:

-

1.5~2 t/h Paddy Rice

-

Processing Material:

-

Rice

-

Where to Use:

-

Rice plant

-

Function:

-

Processing rice

-

OEM Service:

-

Customized

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

MAOSHENG, Hyde-Maosheng

-

Production Capacity:

-

10-20 tons per day

-

Power:

-

20-25KW

-

Weight:

-

1200 KG

-

Product Name:

-

Rice MIlling Machine

-

Rated Capacity:

-

1.5~2 t/h Paddy Rice

-

Processing Material:

-

Rice

-

Where to Use:

-

Rice plant

-

Function:

-

Processing rice

-

OEM Service:

-

Customized

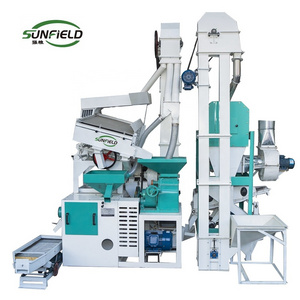

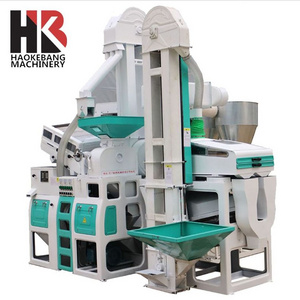

Customizable Professional Manufacturer Combined Rice Cleaner Rice Milling Machine Rice Polishing Machine

Hyde Machinery (Maosheng Group)

- Seed processing plant 1~15 t/h

- Flour mill plant: 40~1000 t/d

- Manufacturer since 1976

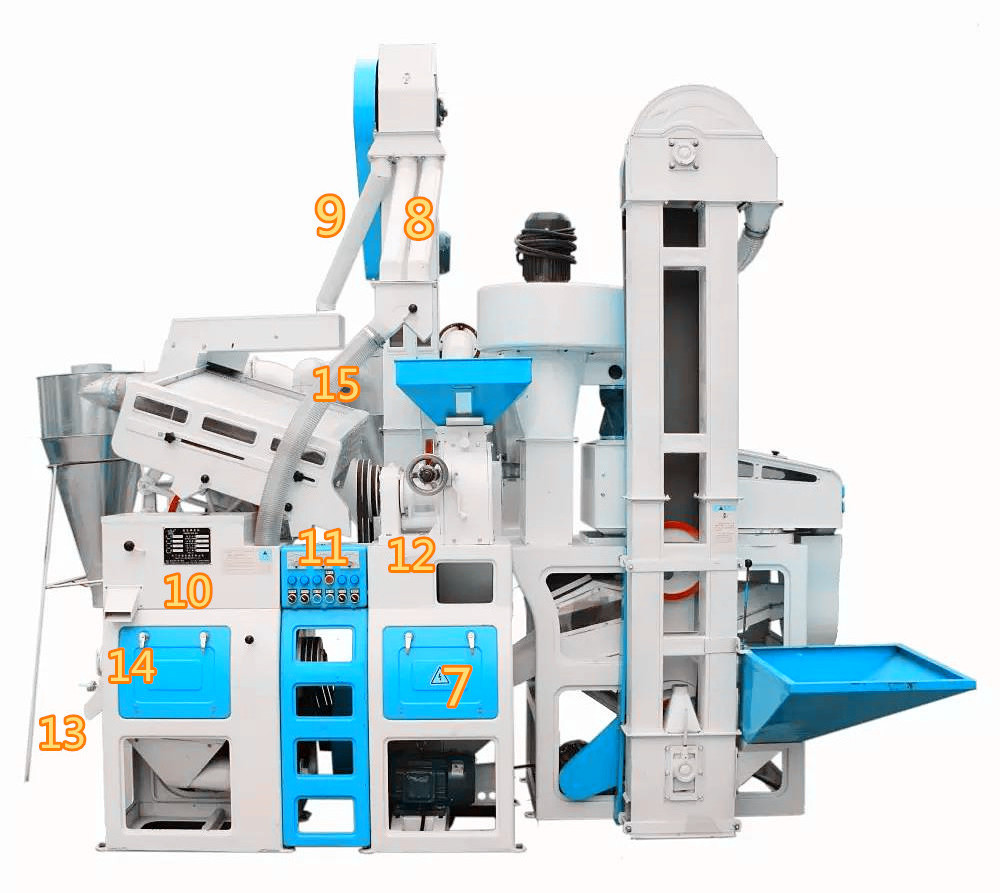

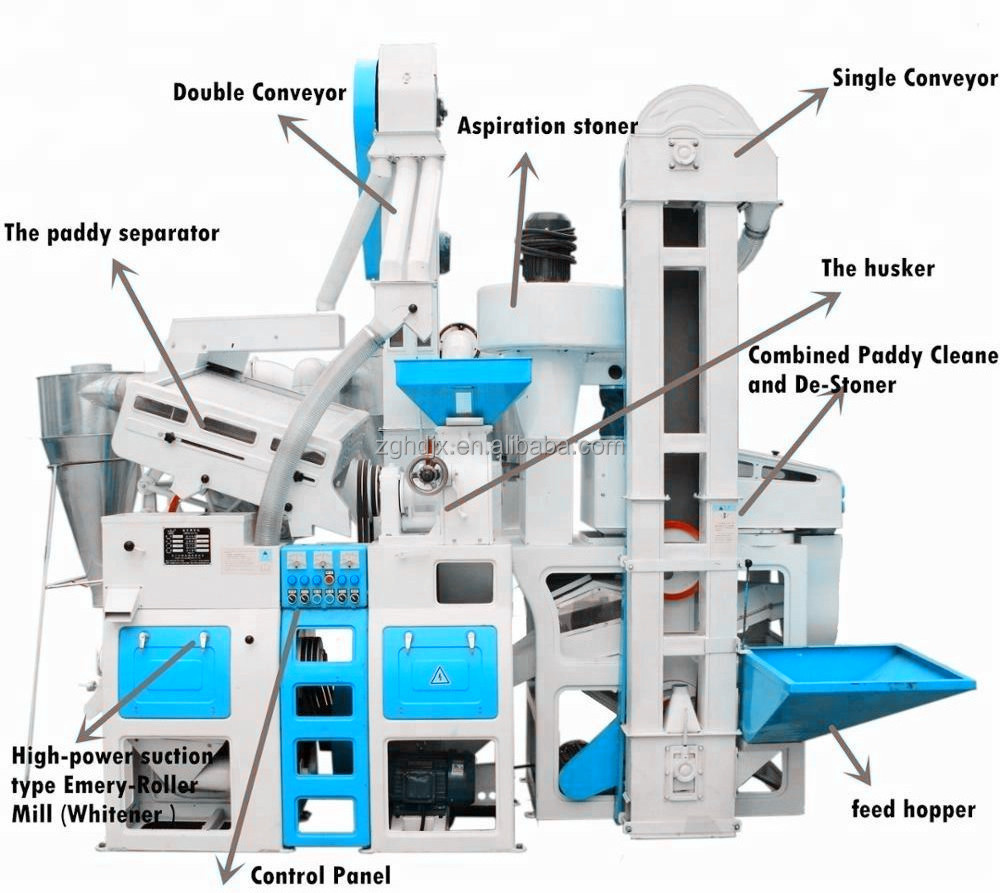

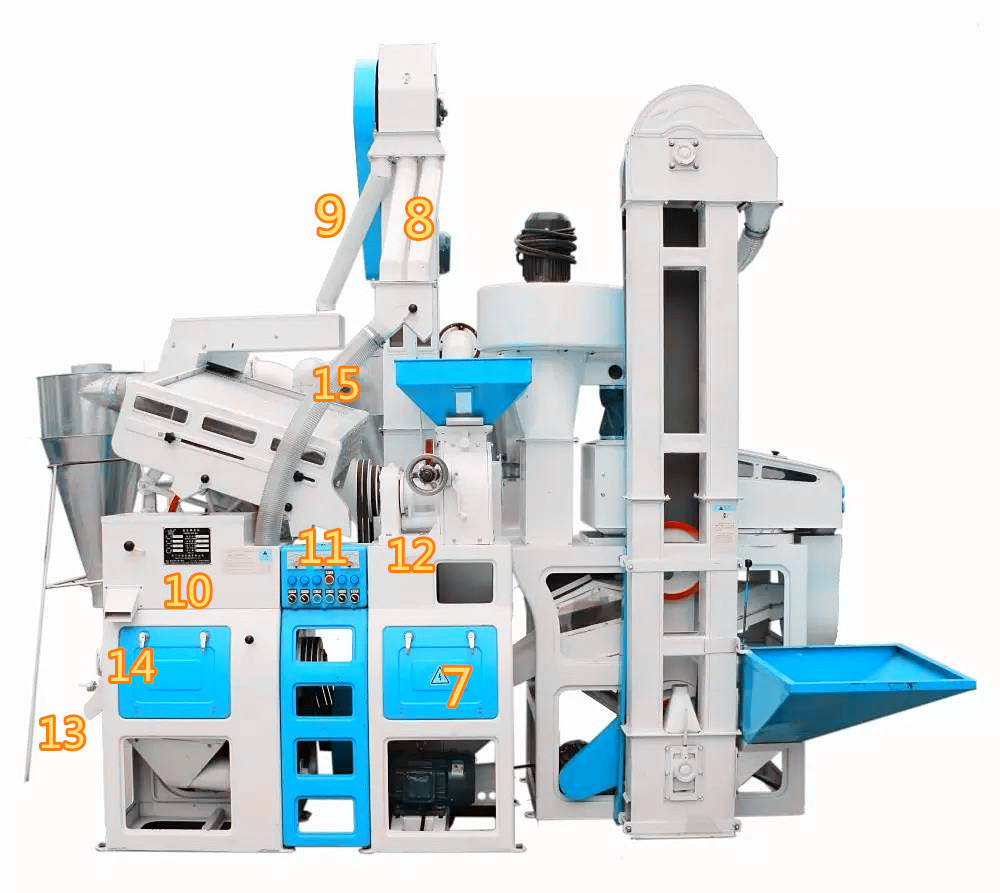

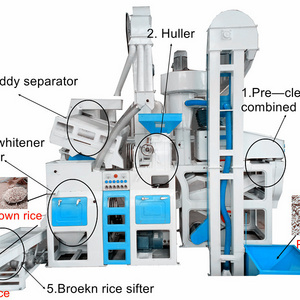

Combine Rice Milling Machine

The Rice Mill Machine is a complete set rice processing equipment, which includes cleaning, destoner, husking, paddy separating and milling sections.You can get edible rice from paddy only with it.the capacity can up to 1200 kg per hour. It is the best choice for you to start a small scale rice milling plant. It can work with rice polishing,color sorter automatic packing machines to be a whole line. Also can process parboiled rice. The output is 1000-1200 kg rice per hour, input 1400-1700 kg paddy per hour.

Product Description

Features and Structure

Combined Rice Milling Line Including

- TF32A Centrifugal Suction Fan.

- TQLQ50A Suction Stoning Machine.

- Single Elevating Conveyor.

- Rubber-roller Husker.

- Double Elevating Conveyor.

- Gravity Paddy Separator.

- Jet-air Emery Roll Rice Mill,

- The Equipment Has Compact Structure, Easy To Use, Convenient Maintenance, Large Output,High Milling Precision And So On.

- Whitened And Polished While Keeping Close Contact With The Emery Roller, Producting Very Few Broken Rice Grains And Making Higher Rice Milling Rate.

-

There Is No Rice Bran Powder In The Finished Ones, The Rice Surface Shows Rounder And Brigher, It Is A Kind Of Advanced Rice Processing Technique.

-

It Is An Ideal Equipment Suitable For Farms, Towns, Grain House Or Rice Processing Specialized Households For Rice Milling Processing System.

- Automatic Combined Rice Milling Line Has Such Advantages Of Compact Structure.

- It Has Easy Operation, Convenient Maintenance, Big Output, High Precision.

- Automatic Combined Rice Milling Line Is Whole Set Combined Paddy Rice Mill For Processing Paddy Rice In Farmlands, Grain Shop And Specialized Households.

- This Automatic Combined Rice Milling Line Features Low Noise And Smooth Operation, With Its Unique Rice Milling Technique, Each Grain Of Rice Can Be Evenly Unshelled.

- Whole Set Combined Rice Mill Main Lincludes: Stone Removal Machine, Husker, Gravity Paddy Separator, High-power Suction System, Emery-roller Rice Mill.

- The Produce Can Cleaner, Destoner, Huller, Paddy Separator, Whitener( Polisher), Grader All In One.

Technical Specification

Whole Rice Milling Plants& Drawings

Grain and seed cleaning machines:

Pre-cleaners, fine cleaners, rotary cleaners, seed graders, seed gravity separators, indented cylinder, wheat paddy de-awner, destoner, vibration cleaner, rotary cleaner, air aspirator, cyclone dust collector, seed treater, seed dryers, elevators and conveyors, auto-packing scales.

Air Screen Fine Cleaner Seed Gravity Separator Indented Cylinder Separator