- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

The Nile

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

1300 KG

-

Application:

-

Stone Powder Grinding

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Product name:

-

Ball Milling Machine

-

Keywords:

-

Grinding Miller Ball Mill

-

Color:

-

Customizable

-

The Machines classification:

-

Ball Mill Grinding Equipment

-

Name:

-

Ball Mill

-

Certification:

-

ISO CE

-

Quality:

-

High Leavel

-

Price:

-

Negotiable Resonable

Quick Details

-

Marketing Type:

-

Hot Product

-

Capacity(t/h):

-

1.4-87

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

The Nile

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

1300 KG

-

Application:

-

Stone Powder Grinding

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Product name:

-

Ball Milling Machine

-

Keywords:

-

Grinding Miller Ball Mill

-

Color:

-

Customizable

-

The Machines classification:

-

Ball Mill Grinding Equipment

-

Name:

-

Ball Mill

-

Certification:

-

ISO CE

-

Quality:

-

High Leavel

-

Price:

-

Negotiable Resonable

Product Description

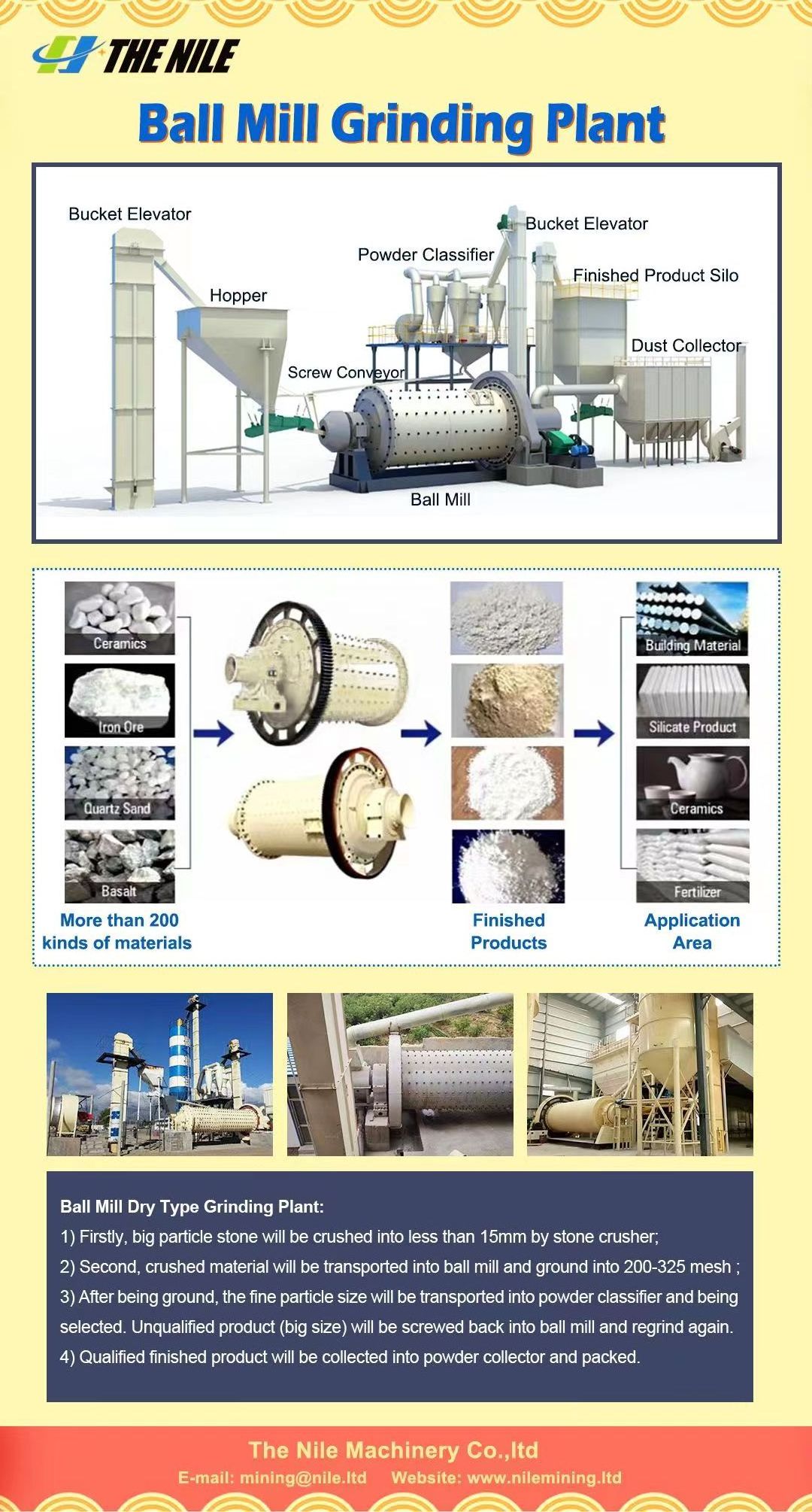

Factory Price Ball Mill Introduction

production lines, such as cement, silicate, new-type building material, refractory material, fertilizer, glass ceramics and

non-ferrous metal etc.

Overseas Service

1. We have engineers in Kenya, Sudan, Uganda, Professional installation and training skills.

2. We have a factory and warehouse in Kenya and China, Fast pre-sale and after-sale service, Wear Parts in stocks, You can get it soon.

3. Our products have been spread all over China, and also exported to European, American, Asian, African countries. Our sales managers and engineers know the local condition very well, We will supply the most suitable solution for you.

Technical Data

|

Model

|

Effective Volume

(m3) |

Balls Weight

(t) |

Feeding Size

(mm) |

Capacity

(t/h) |

Main Reducer

|

Motor power(kw)

|

Weight

(t)

|

|

φ1200*4500

|

4.7

|

6.5

|

≤25

|

1.4-2

|

ZD30

|

45

|

13.1

|

|

φ1500*5700

|

9.4

|

13

|

≤25

|

3.5-4.5

|

ZD40

|

130

|

24

|

|

φ1830*6400

|

15.7

|

21.6

|

≤25

|

5.5-6.5

|

ZD60

|

210

|

38

|

|

φ1830*7000

|

17.1

|

23.5

|

≤25

|

6-7

|

ZD60

|

210

|

43

|

|

φ2200*6500

|

23

|

31.5

|

≤25

|

8-10

|

ZD70

|

380

|

50.2

|

|

φ2200*7500

|

26.5

|

36

|

≤25

|

10-11

|

ZD70

|

380

|

53.2

|

|

φ2200*8000

|

28.3

|

39

|

≤25

|

10-12

|

ZD70

|

380

|

55

|

|

φ2400*11000

|

46.3

|

64

|

≤25

|

19-21

|

ZD80

|

680

|

99.2

|

|

φ2400*13000

|

54.7

|

75.5

|

≤25

|

21-23

|

MBY710

|

800

|

115.2

|

|

φ2600*13000

|

88.6

|

122

|

≤25

|

28-32

|

MBY800

|

1000

|

148

|

|

φ3000*12000

|

78.9

|

109

|

≤25

|

32-35

|

MBY900

|

1250

|

168.6

|

|

φ3000*13000

|

85.5

|

118

|

≤25

|

34-37

|

MBY900

|

1400

|

12.3

|

|

φ3200*13000

|

134.2

|

185

|

≤25

|

45-50

|

MBY1000

|

1600

|

218

|

|

φ3800*13000

|

137.1

|

189

|

≤25

|

60-62

|

MFYX250

|

2500

|

286

|

|

φ4200*13000

|

167.5

|

231

|

≤25

|

85-87

|

MFX355

|

3550

|

320

|

Product Details

Ball Mill advantages:

1. The lining can be replaced.

2. Mineral ball mill is an efficient tool for grinding many materials into fine powder.

3.Two ways of grinding: the dry way and the wet way.

4.Ultimate particle size depends entirely on how hard the material you’re grinding is.

5. As the barrel rotates, the material is crushed between the individual pieces of grinding media that mix and crush the product into fine powder over a period of several hours.

2. Mineral ball mill is an efficient tool for grinding many materials into fine powder.

3.Two ways of grinding: the dry way and the wet way.

4.Ultimate particle size depends entirely on how hard the material you’re grinding is.

5. As the barrel rotates, the material is crushed between the individual pieces of grinding media that mix and crush the product into fine powder over a period of several hours.

Wear Parts Supply:

Customer Site

Overseas Service

1. We have engineers in Kenya, Sudan, Uganda, Professional installation and training skills.

2. We have a factory and warehouse in Kenya and China, Fast pre-sale and after-sale service, Wear Parts in stocks, You can get it soon.

3. Our products have been spread all over China, and also exported to European, American, Asian, African countries. Our sales managers and engineers know the local condition very well, We will supply the most suitable solution for you.

Packing & Delivery

Ways of Packing:

1. Sand blasting, coat with high quality paint;

2. Product wrap by PP-Bubble

3. Load container, Spear Parts in wooden case.

Transportation:

1. By sea Freight;

2. MSK/MSC/APL/EMC/WANHAI/KLINE

3. We will remind you before boat arrival

1. Sand blasting, coat with high quality paint;

2. Product wrap by PP-Bubble

3. Load container, Spear Parts in wooden case.

Transportation:

1. By sea Freight;

2. MSK/MSC/APL/EMC/WANHAI/KLINE

3. We will remind you before boat arrival

Hot Searches