- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

YaYuan

-

Weight:

-

3.5t

-

Dimension(L*W*H):

-

1700*1350*3550mm

-

Name:

-

paper baler machine

-

Product name:

-

vertical baler

-

Keyword:

-

waste paper baler machine

-

Number of hydraulic cylinders:

-

2

-

Block Size:

-

900*1100*500mm

-

Block Weight:

-

300-350kg

-

Output:

-

3.5-4t/h

-

Main push force:

-

1000kn

-

Certification:

-

ISO9001

Quick Details

-

Voltage:

-

380V

-

Power:

-

11kw

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YaYuan

-

Weight:

-

3.5t

-

Dimension(L*W*H):

-

1700*1350*3550mm

-

Name:

-

paper baler machine

-

Product name:

-

vertical baler

-

Keyword:

-

waste paper baler machine

-

Number of hydraulic cylinders:

-

2

-

Block Size:

-

900*1100*500mm

-

Block Weight:

-

300-350kg

-

Output:

-

3.5-4t/h

-

Main push force:

-

1000kn

-

Certification:

-

ISO9001

Product Application of

paper baler machine

1. The hydraulic baler press machine make the waste paper, cardboard, carton, waste plastic, cans, aluminum, coconut, used clothes, cotton, straw, tire and other loose material compressed into a block, so that we can store, transport and utilize them easily expediently.

2.Hydraulic baler machine is widely used in Recycling center and Packaging plant, which has a great effect on environment and resource protection.

Specification for paper baler machine

2. The bale size is adjustable according to your requirements.

3. Different material, different density, different weight.

This parametere only for reference. More details, Please contact us!

|

Model

|

YYL-15

|

YYL-30

|

YYL-60

|

YYL-80

|

YYL-100

|

YYL-120

|

|

Main push force (Kn)

|

150

|

300

|

600

|

800

|

1000

|

1200

|

|

Power(Kw)

|

5.5

|

7.5

|

7.5-11

|

7.5-11

|

7.5-11

|

15-18

|

|

Block Size (mm)

|

300*600*5 00

|

400*800*5 00

|

600*900*5 00

|

900*1100* 500

|

900*1100* 500

|

900*1100* 500

|

|

Block Weight(kg)

|

50-80

|

100-150

|

200-300

|

300-350

|

300-350

|

300-350

|

|

Output (T/H)

|

1-1.5t/h

|

1.5-2t/h

|

2-2.5t/h

|

2-2.5t/h

|

3.6-4t/h

|

4-5t/h

|

|

Host Machine

Dimension (mm)

|

1500*600* 3000

|

1500*600* 3000

|

1700*1250 *3400

|

1700*1350 *3550

|

1700*1350 *3550

|

1700*1350 *3550

|

|

Host Machine

Weight

|

0.8-1t

|

1.5t

|

2t

|

3t

|

3.5t

|

4t

|

|

Number of hydraulic cylinders

|

1

|

1

|

2

|

2

|

2

|

2

|

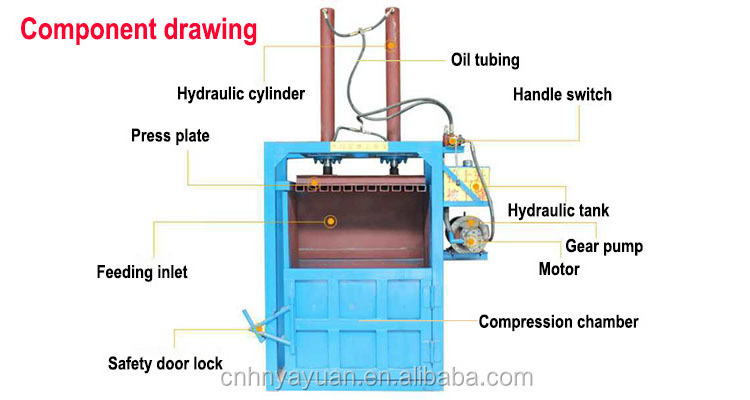

Main Features of briquetting paper baler machine

1,Made of high-strength steel and special welding processes, it is extremely strong.

2,Intelligent control, simple operation, emergency stop device, low failure rate.

3,Wide range of applications, such as supermarkets, small-scale recycling plants and other places that require compaction functions, saving storage space and reducing transportation costs.

4,No door design can increase production efficiency and save costs

5,Adopt imported electrical components for reliable quality and durability

Briquetting case display

About Us

Our company has advanced production equipment and first-class technical talents. According to the different conditions proposed by customers. We can design product solutions that meet the actual needs of customers, and provide pre-sales, sales, and after-sales full-service, which can solve actual production for customers and Any problem in operation.

Our company adheres to the principle of honesty , and serves our customers as our purpose. We are constantly pioneering and innovating so that our products are well received by customers both at home and abroad.

Welcome friends from all over the world to visit our company and discuss cooperation.

Packaging details: sea worthy wooden case or iron box ,or container

Delivery Time:15-20 days after deposit

Supply ability:100 Set/Sets per Month

Port:Qingdao

|

1,

What kind of items can be pressed into a block by this machine?

A:Such as clothing, straw, cotton, hemp, fur, cotton yarn, waste paper, waste plastics, beverage bottles, herbs, tobacco,Sawdust and other Loose material. |

|

|

|

|||

|

2

,What can we do when the machine doesn't work?

A:We will focus on your needs all the time and serve you with all-round carefulness and consideration, even send our engineer to serve you until the problem be done. |

|

|

|

|||

|

3,How does the hydraulic system work?

A:It is controlled by the hydraulic station which is composed of hydraulic pump, solenoid valve and hydraulic oil. |

|

|

|

|||

1,Quality assurance period is 1 year for the whole machine, but the failures caused by operational errors are the responsibility of the customer.

2,We will test all machines before shipment to ensure that the equipment you receive is normal.

3,We have technical personnel to abroad to install and commission, and train your workers until they can be produced independently.

4,You can contact us at any time if you have problems .

5,Special sizes can be custom-made specially.