- Product Details

- {{item.text}}

Quick Details

-

Material:

-

Stainless steel

-

Tensile Strength:

-

custom for Transmission Chains

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

heavy duty iron chain

-

Product name:

-

Custom Heavy Duty Malleable Cast Iron Chain With Logo

-

Process:

-

Forged or Stamping

-

Casting Tolerance:

-

CT4-9 for stainless steel round chain

-

Surface Treatment:

-

Polishing,Plating,Powder coating etc. As customers request

-

Quality Control:

-

Strictly 100% Inspection

-

Packing:

-

Multilayer wooden box/pallet, with big plastic bag inside

-

Service:

-

OEM ODM Customized

-

Lead Time:

-

30-45days for heavy duty iron chain

-

MOQ for mass production:

-

1pcs normally for conveyor short pitch hollow pin roller chain

Quick Details

-

Applicable Industries:

-

Manufacturing Plant, Farms, Construction works

-

Standard or Nonstandard:

-

Standard

-

Type:

-

Roller Chain

-

Material:

-

Stainless steel

-

Tensile Strength:

-

custom for Transmission Chains

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

heavy duty iron chain

-

Product name:

-

Custom Heavy Duty Malleable Cast Iron Chain With Logo

-

Process:

-

Forged or Stamping

-

Casting Tolerance:

-

CT4-9 for stainless steel round chain

-

Surface Treatment:

-

Polishing,Plating,Powder coating etc. As customers request

-

Quality Control:

-

Strictly 100% Inspection

-

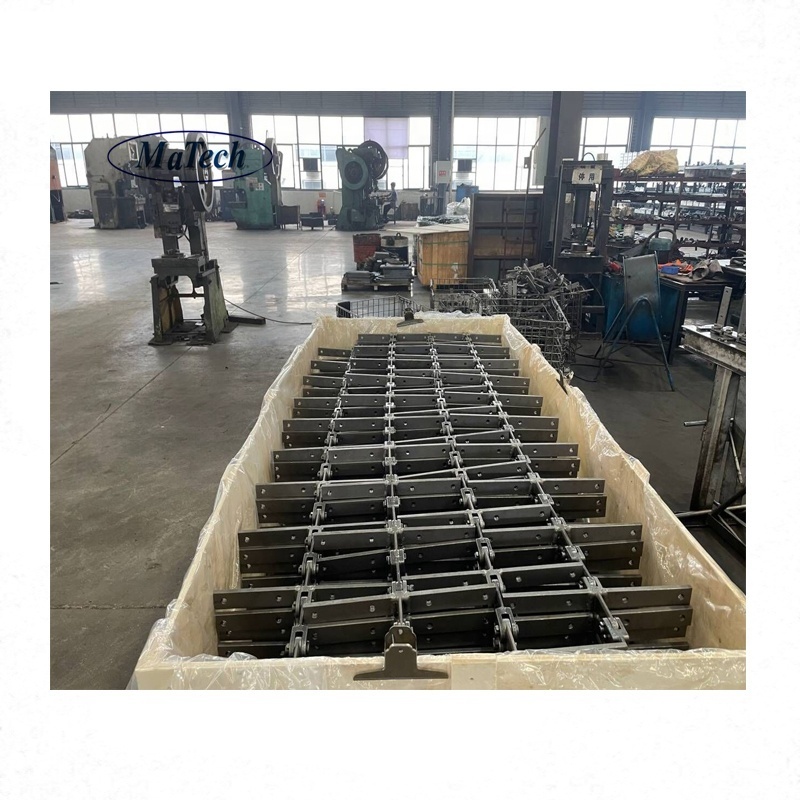

Packing:

-

Multilayer wooden box/pallet, with big plastic bag inside

-

Service:

-

OEM ODM Customized

-

Lead Time:

-

30-45days for heavy duty iron chain

-

MOQ for mass production:

-

1pcs normally for conveyor short pitch hollow pin roller chain

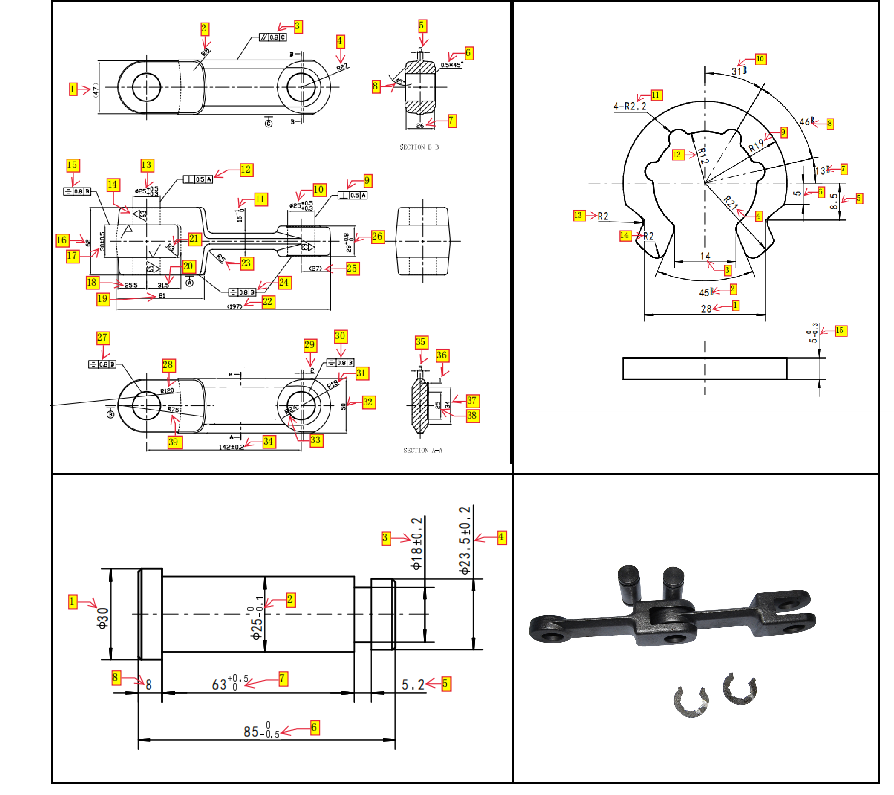

scraper conveyor chain

The

scraper conveyor chain

can be used to transport bulk materials in horizontal, inclined and vertical directions. It is often used for the transportation of raw grain, semi-finished products and finished products in grain and oil, feed processing plants. The scraper conveyor chain is suitable for the transportation of oil in the production process of grease processing plants. Transportation of raw grain from grain warehouse.

It has the advantages of simple structure, good sealing, simple feeding and unloading device, multi-point feeding and unloading, flexible layout, and the ability to complete material transportation in multiple directions at the same time.

The scraper conveyor chain of Shanghai MATECH Chain Factory adopts

medium carbon quenched and tempered steel and cold heading die steel. The steel is moderately priced and easy to process. After proper heat treatment, a certain degree of toughness, plasticity and wear resistance can be obtained. Normalizing can promote the spheroidization of the structure and is suitable for surface hardening treatments such as high-frequency quenching and flame quenching.

Application:

After quenching and tempering, it can be used to manufacture medium load and medium speed work.

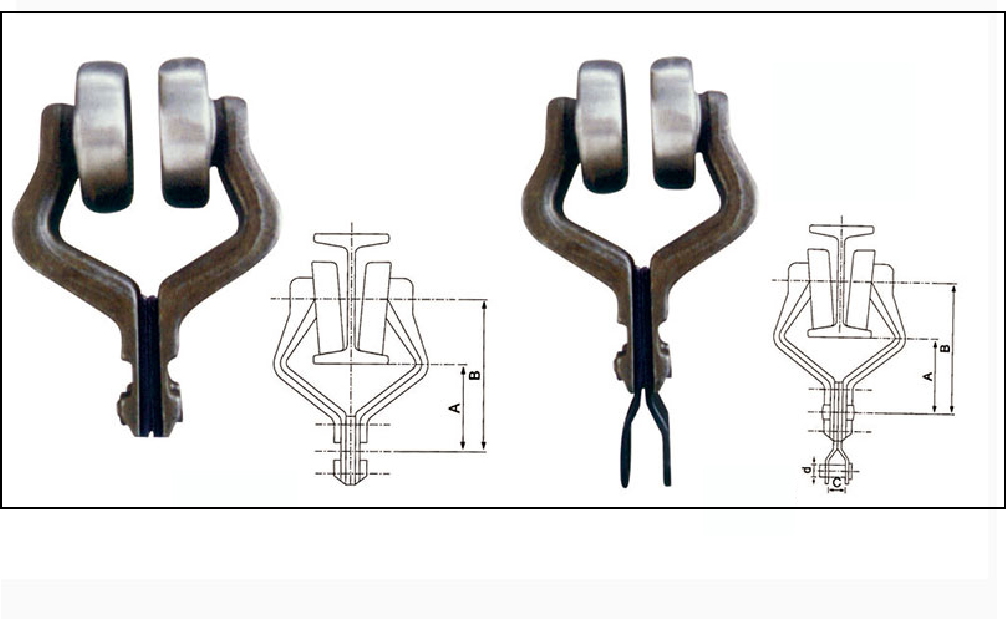

The working principle of the scraper conveyor

is to use the open chute as a bearing part for coal, gangue or materials, and fix the scraper on the chain (to form a scraper chain) as a traction member. When the driving part of the machine head starts, the sprocket on the driving head shaft rotates, so that the scraper chain circulates and moves the animal material along the chute until it reaches the machine head to unload. The scraper chain bypasses the sprocket and runs in a stepless closed loop to complete the transportation of materials.

Other scraper conveyor chain

uses and maintenance precautions have to be communicated with the supplier. The above information is for reference only.

Our advantage:

We have very strict quality control process

:

1.In coming Quality control (IQC). -----All incoming raw material are checked before used.

2. In process quality control (IPQC) . -----Perform inspections during the manufacturing process.

3. Final quality control (FQC) . -----All finished goods are inspected according to our quality standard for each products.

4. Outgoing Quality Control (OQC) . -----Our QC team will 100% full inspection before it goes out for shipment.

5. Proper Quarantine procedure . -----For those products got rejected to pass the quality control, they will specially marked and dispose.

Products Description

|

Product Name

|

Custom Heavy Duty Malleable Cast Iron Chain With Logo

|

|

Brand Name

|

MATECH

|

|

Process

|

Forged or Stamping

|

|

Material

|

20CrMnTi,2Cr13 etc. As customers request.

|

|

Casting Tolerance

|

CT4-9 for Stainless Steel Chain

|

|

Surface Treatment

|

Polishing,Plating,Powder coating etc. As customers request

|

|

Quality Control

|

Strictly 100% Inspection

|

|

Service

|

OEM ODM Customized

|

|

Packing

|

Multilayer wooden box/pallet, with big plastic bag inside

|

|

Lead Time

|

30-45 days for stainless steel round chain

|

|

MOQ for mass production

|

1pcs accept for sample test

|

Main Products

We can provide customized services according to your drawings,welcome to Contact us to learn more !

Transportation Suspension Chain

Heavy Duty Chain

Plate chain

Scraper Chain

Pin Chain

Conveyor Chain

Product Application

Main Facilities

NC Sawing

NC Turning

Heat Treatment

HF Rivet

NC Flame Cutting

Press Machine

Quality Control

Packing & Delivery

Multilayer wooden box/pallet, with big plastic bag inside (or as your requirements

) to ensure the goods are in good condition.

Our Advantages

Hot Searches