- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

SDK

-

Theory:

-

Hall Sensor

-

Output:

-

Digital Sensor

-

Application:

-

Wide Range

-

Operate Condition:

-

Operation from 2.5V to 6V

-

Feature:

-

High sensitivity

-

Item:

-

Omnipolar Hall effect sensor IC

-

Operating Temperature:

-

-40 to 85 ℃

-

Storage Temperature:

-

-50 to 150 ℃

-

ESD Sensitivity:

-

4000 V

Quick Details

-

Use:

-

Other

-

Model Number:

-

ST3253

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SDK

-

Theory:

-

Hall Sensor

-

Output:

-

Digital Sensor

-

Application:

-

Wide Range

-

Operate Condition:

-

Operation from 2.5V to 6V

-

Feature:

-

High sensitivity

-

Item:

-

Omnipolar Hall effect sensor IC

-

Operating Temperature:

-

-40 to 85 ℃

-

Storage Temperature:

-

-50 to 150 ℃

-

ESD Sensitivity:

-

4000 V

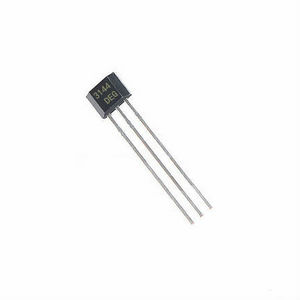

ST3253 CMOS Omnipolar High Sensitivity Hall Switch

The ST3253 Omnipolar Hall effect sensor IC is fabricated from mixed signal CMOS technology .It incorporates advanced chopper-stabilization techniques to provide accurate and stable magnetic switch points.

The output transistor of the ST3253 will be latched on (BOP) in the presence of a sufficiently strong South or North magnetic field facing the marked side of the package. The output will be latched off (BRP) in the absence of a magnetic field.

Absolute Maximum Ratings

DC Electrical Characteristics

Magnetic Characteristics

Operating Parameters: T A = 25?, V DD =5V DC .

CMOS Hall IC Technology

The chopper stabilized amplifier uses switched capacitor techniques to eliminate the amplifier offset voltage, which, in bipolar devices, is a major source of temperature sensitive drift. CMOS makes this advanced technique possible. The CMOS chip is also much smaller than a bipolar chip, allowing very sophisticated circuitry to be placed in less space. The small chip size also contributes to lower physical stress and less power consumption.

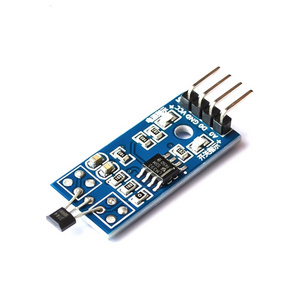

Installation Comments

Consider temperature coefficients of Hall IC and magnetics , as well as air gap and life time variations. Observe temperature limits during wave soldering. Typical IR solder-reflow profile:

No Rapid Heating and Cooling.

Recommended Preheating for max. 2minutes at 150°C

Recommended Reflowing for max. 5seconds at 240°C