- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

0

-

CrO Content (%):

-

0

-

SiC Content (%):

-

0

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

R-HA

-

Brand Name:

-

Tk Brics

-

Application:

-

Furnace Liner

-

Size:

-

Customized Size

-

Raw material:

-

High Alumina Bauxite

-

Keyword:

-

High Alumina

-

Package:

-

Wooden Pallet

-

Cold Crush Strength:

-

45-80 Mpa

-

Certificate:

-

ISO BV S.GS

-

Delivery time:

-

10-15days

-

Modulus of Rupture:

-

70-80

Quick Details

-

SiO2 Content (%):

-

38.2

-

Al2O3 Content (%):

-

48-55

-

MgO Content (%):

-

0

-

CaO Content (%):

-

0

-

CrO Content (%):

-

0

-

SiC Content (%):

-

0

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

R-HA

-

Brand Name:

-

Tk Brics

-

Application:

-

Furnace Liner

-

Size:

-

Customized Size

-

Raw material:

-

High Alumina Bauxite

-

Keyword:

-

High Alumina

-

Package:

-

Wooden Pallet

-

Cold Crush Strength:

-

45-80 Mpa

-

Certificate:

-

ISO BV S.GS

-

Delivery time:

-

10-15days

-

Modulus of Rupture:

-

70-80

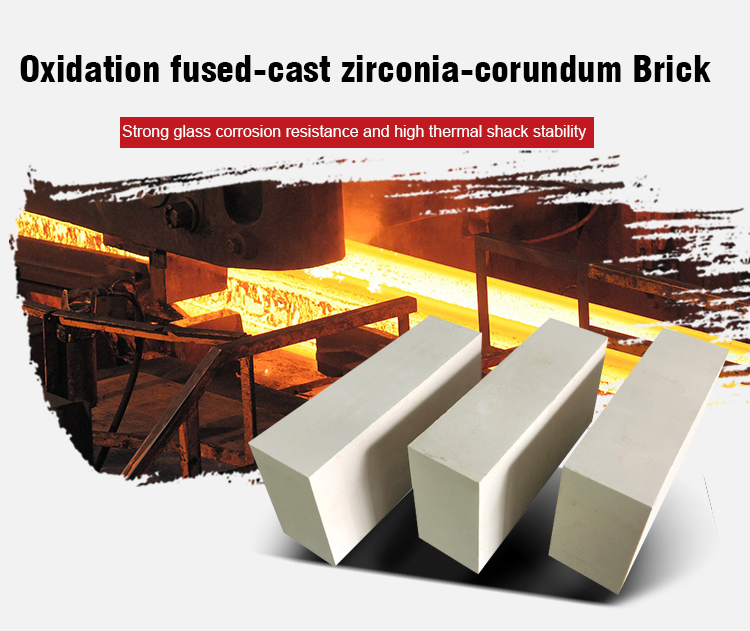

Oxidation fused-cast zirconia-corundum Products

The fused zircon corundum brick is a white solid formed by pure alumina powder and zircon sand containing zirconia of 65% and about 34% of silica in the electric melting furnace and then injected into the mold to be cooled.

Zircon brick / Zirconia bricks have the advantage of mechanical strength, excellent stability to thermal shock, resistance to

corrosion, high refractoriness under load and inertness, high density, etc. It is widely used in glass furnace, non-ferrous metal smelting furnace, and pure steel furnace. Please see listed applications on lower right of this page.

TK BRICKS can produce serious fused cast 33#,36#,41#AZS block for glass furnace.

We can produce common shaped and irregular shaped refractory brick.And we can adjust our specifications for your application.

Zircon brick / Zirconia bricks have the advantage of mechanical strength, excellent stability to thermal shock, resistance to

corrosion, high refractoriness under load and inertness, high density, etc. It is widely used in glass furnace, non-ferrous metal smelting furnace, and pure steel furnace. Please see listed applications on lower right of this page.

TK BRICKS can produce serious fused cast 33#,36#,41#AZS block for glass furnace.

We can produce common shaped and irregular shaped refractory brick.And we can adjust our specifications for your application.

|

Specification

|

|

|

|

|

||||

|

ITEM

|

Mullite Bricks

|

SPEC

|

Mullite-Corundum Bricks

|

Corundum-Mullite Bricks

|

||||

|

Al2O3

|

≥70%

|

AZS-33#

ER 1681 |

AZS-36#

ER 1685 |

AZS-41#

ER 1711 |

||||

|

Chemical

Composition

|

Al2O3

|

≥50.00

|

≥49.00

|

≥45.00

|

||||

|

Fe2O3

|

ZrO2

|

≥32.50

|

≥35.50

|

≥40.50

|

||||

|

Bulk Density

|

SiO2

|

≤15.50

|

≤13.50

|

≤13.00

|

||||

|

Initial Refractoriness Under Load/℃

|

Na2O+K2O

|

≤1.30

|

≤1.35

|

≤1.30

|

||||

|

Bulk density g/cm3

|

|

≥3.75

|

≥3.85

|

≥4.00

|

||||

|

Apparent Porosity %

|

≥90MPa

|

≤1.2

|

≤1.0

|

≤1.2

|

||||

|

Cold Crushing Strength Mpa

|

|

≥300

|

≥300

|

≥300

|

||||

|

Exudation Temperature of Glass Phase

|

|

≥1400

|

≥1400

|

≥1410

|

||||

|

Bubble Separation Ratio(1300°C×10h)

|

|

≤1.2

|

≤1.0

|

≤1.0

|

||||

|

Anti-corrosion rate of glass liquid

1500°C×36h (mm/24h)%

|

|

≤1.4

|

≤1.3

|

≤1.2

|

||||

|

Apparent density

(g/cm3)

|

PT(RN RC N)

|

≥3.50

|

≥3.50

|

≥3.70

|

||||

|

|

ZWS(RR EVF EC ENC)

|

≥3.65

|

≥3.70

|

≥3.90

|

||||

|

|

WS( RT VF EPIC FVP DCL)

|

≥3.75

|

≥3.8

|

≥4.00

|

||||

Hot Searches