- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

5000L

-

Weight (KG):

-

680 KG

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

LINHE

-

Voltage:

-

Customized

-

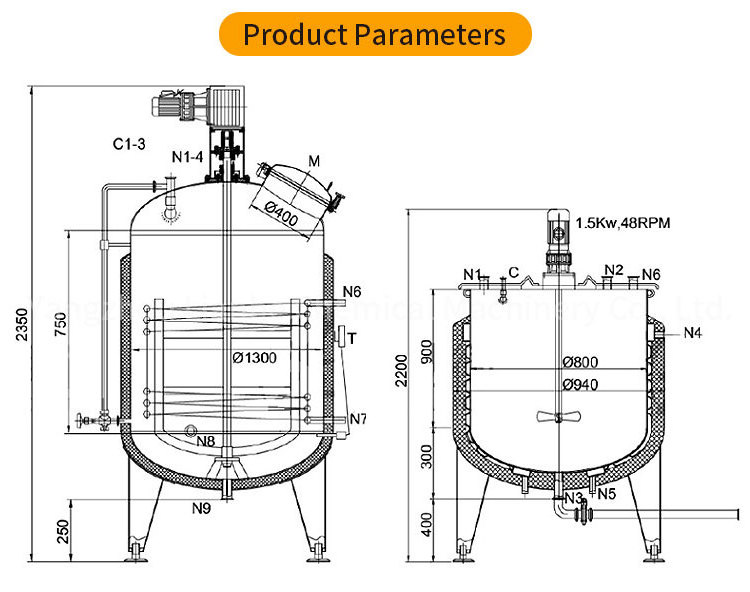

Dimension(L*W*H):

-

1100*1300*1900

-

Power (kW):

-

15 kW

-

Marketing Type:

-

New Product 2022

-

Product Name:

-

stainless steel Liquid Mixer Detergent Mixing tank

-

Structure:

-

Single/double jacket/three layers

-

Capacity:

-

50-5000L

-

Motor:

-

ABB/SIEMENS

-

volume:

-

customerized

-

Heating Method:

-

Electric heating or steam heating

-

Other names:

-

Reactor, vessel, Mixing Equipment

-

Keyword:

-

Mixing Tank With Agitator

Quick Details

-

Barrel Volume (L):

-

100

-

Max. Loading Volume (L):

-

5000 L

-

Range of Spindle Speed(r.p.m):

-

1 - 2880 r.p.m

-

Max. Loading Capacity:

-

5000L

-

Weight (KG):

-

680 KG

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

LINHE

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

1100*1300*1900

-

Power (kW):

-

15 kW

-

Marketing Type:

-

New Product 2022

-

Product Name:

-

stainless steel Liquid Mixer Detergent Mixing tank

-

Structure:

-

Single/double jacket/three layers

-

Capacity:

-

50-5000L

-

Motor:

-

ABB/SIEMENS

-

volume:

-

customerized

-

Heating Method:

-

Electric heating or steam heating

-

Other names:

-

Reactor, vessel, Mixing Equipment

-

Keyword:

-

Mixing Tank With Agitator

Product Description

◭

This equipment is mainly used in storing material used in food, chemical industries and it is indispensable storage equipment for them. You can have it made by SUS304, S.S.316L, stainless steel or Q235B carbon steel. It is reasonably designedm produced by advanced technology and confirm to GMP requirement.

The inner surface of the tank can be mirror polished and the roughness can meet as high as RA <=0.8um. The outer surface is polished as follows: the cover and the bottom will be mirror polished and the remaining part will be mat polished. All the polish meet international standard.

◭ Features:

Material: SUS304 or S.S.316L

Agitator type: Anchor, frame, or paddle type. ( can be customerized).

Mixing structure: cycloid pin wheel reducer or stepless reducer

Sealing device: mechnical sealing or dual-face water cooled sealing

Heating way: electric heating,steam heating

Volume: can be made as per customer requirements, volume can be made from 50L to max.5000L.

Measure: can be made as per customer requirements.

The inner surface of the tank can be mirror polished and the roughness can meet as high as RA <=0.8um. The outer surface is polished as follows: the cover and the bottom will be mirror polished and the remaining part will be mat polished. All the polish meet international standard.

◭ Features:

Material: SUS304 or S.S.316L

Agitator type: Anchor, frame, or paddle type. ( can be customerized).

Mixing structure: cycloid pin wheel reducer or stepless reducer

Sealing device: mechnical sealing or dual-face water cooled sealing

Heating way: electric heating,steam heating

Volume: can be made as per customer requirements, volume can be made from 50L to max.5000L.

Measure: can be made as per customer requirements.

|

Capacity

|

50-5000L

|

|

|

|

|||

|

Layers

|

Single layer/ Double layers(heating)/ Three layers(Insulation layer)

|

|

|

|

|||

|

Heating mode

|

Electric heating, Steam heating, Gas heating

|

|

|

|

|||

|

Motor power

|

0.75-5.5kw

|

|

|

|

|||

|

Material

|

SS304/SS316L

|

|

|

|

|||

|

Jacket

|

Full jacket ,Dimple jacket , Coil tube

|

|

|

|

|||

|

Mixing Type

|

High shear mixer or Agitator ( Anchor ,Oblique leaf blade, Ping ye rushton turbine,Cloverpropelled)

|

|

|

|

|||

How to choose

|

Model

|

Working Capacity

(L)

|

Mixing Power

(KW)

|

Mixing Speed

(rpm)

|

Heating Method

|

|

LH-50

|

50

|

0.75

|

0-63

|

Electric Heating

|

|

LH-100

|

100

|

1.1

|

0-63

|

|

|

LH-200

|

200

|

1.1-2.2

|

0-63

|

|

|

LH-300

|

300

|

1.5-2.2

|

0-63

|

|

|

LH-500

|

500

|

4.0-5.5

|

0-63

|

|

|

LH-1000

|

1000

|

4.0-7.5

|

0-63

|

Electric Heating/

Steam Heating

|

|

LH-1500

|

1500

|

5.5-7.5

|

0-63

|

|

|

LH-2000

|

2000

|

5.5-7.5

|

0-63

|

|

|

LH-3000

|

3000

|

11-15

|

0-63

|

|

|

LH-5000

|

5000

|

18.5-22

|

0-63

|

|

Product Show

Thank you for visiting our web. Hope you can find what you need here. For a more efficient communication, please refer to the

following question when sending the inquiry.

1. What product you want to produce?

2. What capacity of the mixer do you need? Or what’s your planing daily output?

3. Do you have any special request for the machine?

1. What product you want to produce?

2. What capacity of the mixer do you need? Or what’s your planing daily output?

3. Do you have any special request for the machine?

Factory Show

Hot Searches