- Product Details

- {{item.text}}

Quick Details

-

Type:

-

corer machine

-

Voltage:

-

380v

-

Power:

-

1.87kw

-

Weight:

-

760kg

-

Dimension(L*W*H):

-

3000*1280*1410

-

Year:

-

2019

-

Certification:

-

CE,ISO

-

Raw material:

-

Plum seed/Cherry/ apricot /peach /olives /cherry /plum

-

Final product:

-

Fruit without core

-

Service:

-

24 Hours Online

-

Color:

-

Customers' Requirements

-

Key words:

-

Fruit Sclier

-

MOQ:

-

1 Set

Quick Details

-

Place of Origin:

-

Henan

-

Brand Name:

-

Runxiang

-

Model Number:

-

PGQH-500

-

Type:

-

corer machine

-

Voltage:

-

380v

-

Power:

-

1.87kw

-

Weight:

-

760kg

-

Dimension(L*W*H):

-

3000*1280*1410

-

Year:

-

2019

-

Certification:

-

CE,ISO

-

Raw material:

-

Plum seed/Cherry/ apricot /peach /olives /cherry /plum

-

Final product:

-

Fruit without core

-

Service:

-

24 Hours Online

-

Color:

-

Customers' Requirements

-

Key words:

-

Fruit Sclier

-

MOQ:

-

1 Set

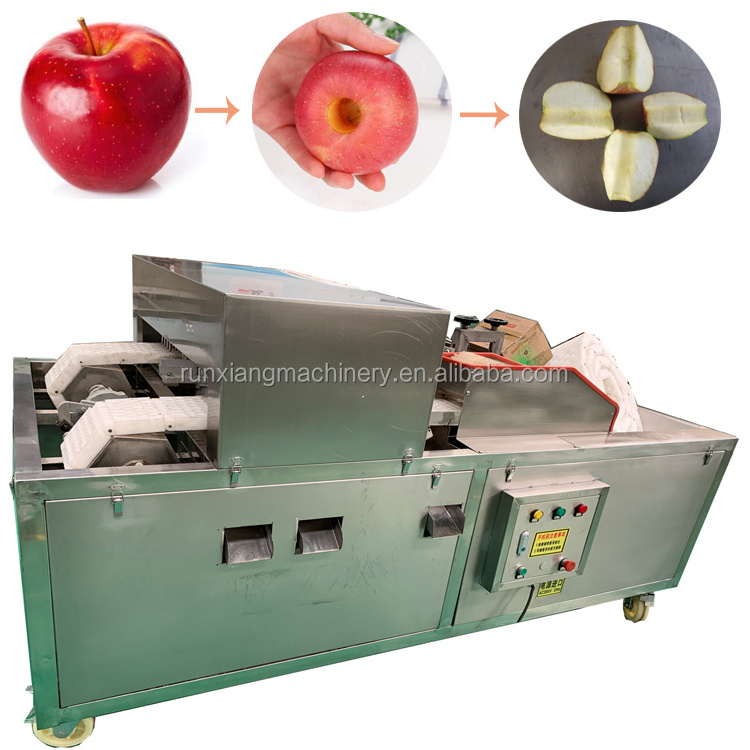

Product Description

Description:

(1) The apple denuclearizer uses a high degree of automation. The mold conveyor is manually placed into the material, and the

automatic feeding device is used for conveying and rushing. The fruit can be separated by placing the fruit on the template, which

can continue uninterrupted. The work has completely solved the difficulties of low manual denuclearization efficiency, labor and

time.

(2) The structure of the denuclearizer is made of 304 stainless steel thick-walled square tube and channel steel, which makes the

equipment more stable during startup and operation. All parts are bolted and assembled to make the equipment more convenient to

operate and maintain. Fast.

(3) The raw materials of the equipment are made of high-quality 304 stainless steel, which fully meets the hygienic standards of

food processing equipment. The conveyor belt is made of imported polyurethane materials, which is resistant to abrasion, tensile

and tearing, and has a longer service life.

(4) The operation of the denuclearizer is simple and convenient. It does not require long-term care, and only 2-4 people need to

place the fruit. The transmission system uses advanced design concepts and standardized components. Each device meets the highest

design standards, with high precision, so that the core removal rate can reach 100%, and the fruit shape is completely unchanged.

Overview:

The storage hopper and the conveyor belt are directly combined, and the template is selected according to the diameter of the

fruit. The fruit is poured into the storage hopper. Only four people need to place it in the template hole to achieve the effect

of feeding and conveying. The fruit continues to be transported and advanced. During the process of fruit transportation, the

fruit is flushed using the process of the machine tool. The core falls into the nuclear dustpan and automatically flows out and is

collected together. The shape of the discharged fruit is completely unchanged, and the fruit falls into the dustpan and

automatically flows out to collect together, thereby achieving separation of the fruit and the core.

(1) The apple denuclearizer uses a high degree of automation. The mold conveyor is manually placed into the material, and the

automatic feeding device is used for conveying and rushing. The fruit can be separated by placing the fruit on the template, which

can continue uninterrupted. The work has completely solved the difficulties of low manual denuclearization efficiency, labor and

time.

(2) The structure of the denuclearizer is made of 304 stainless steel thick-walled square tube and channel steel, which makes the

equipment more stable during startup and operation. All parts are bolted and assembled to make the equipment more convenient to

operate and maintain. Fast.

(3) The raw materials of the equipment are made of high-quality 304 stainless steel, which fully meets the hygienic standards of

food processing equipment. The conveyor belt is made of imported polyurethane materials, which is resistant to abrasion, tensile

and tearing, and has a longer service life.

(4) The operation of the denuclearizer is simple and convenient. It does not require long-term care, and only 2-4 people need to

place the fruit. The transmission system uses advanced design concepts and standardized components. Each device meets the highest

design standards, with high precision, so that the core removal rate can reach 100%, and the fruit shape is completely unchanged.

Overview:

The storage hopper and the conveyor belt are directly combined, and the template is selected according to the diameter of the

fruit. The fruit is poured into the storage hopper. Only four people need to place it in the template hole to achieve the effect

of feeding and conveying. The fruit continues to be transported and advanced. During the process of fruit transportation, the

fruit is flushed using the process of the machine tool. The core falls into the nuclear dustpan and automatically flows out and is

collected together. The shape of the discharged fruit is completely unchanged, and the fruit falls into the dustpan and

automatically flows out to collect together, thereby achieving separation of the fruit and the core.

|

Power

|

kw

|

1.87

|

|

Voltage

|

V

|

380

|

|

Pitting rate

|

%

|

100

|

|

Capacity

|

kg/h

|

9000 pieces /h

|

|

Apple size(mm)

|

Diamater

|

60-90

|

|

Size(mm)

|

(length*width*height)

|

3000×1280×1410

|

|

Weight

|

(kg)

|

760

|

Cutting knives

使用说明

This cutting knives are used to cut apples into pieces,it is customized,if customers do not need apple pieces,then need not this.If customers need apple pieces,this spare parts are free for customers.

-

Description of application effect

-

使用效果描述

Final apple pieces

Detailed Images

Here is detail of this apple corer machine

Related Products

Packing&Shipping

1.Wooden cases packing with plastic roller packing first.

2.It can be customized as the different requirement of different customers.

After Sales Service

Company Introduction

Established in 2012, Zhengzhou Runxiang Machinery Equipment Co.,ltd(Golden Machinery Equipment Co.,Limited) is one professional manufacturer integrating R&D,manufacturing and trading,we are committed to farm agriculture machine line from sheller machine,grinder machine,feed pellet machine,drying machine and packing machine for years,We have 80 staff members and 16 technicians of research team. So we have more competitive strength,advanced processing technology and scientific management.And we are located in Zhengzhou city,Henan province,which is the business and economy center with easy transportation.Our international airport name is Zhengzhou Xinzheng International Airport.

Taking "Sincerity makes trust, Quality wins market"as our business philosophy, Our company always put quality in the first place and meet our customers' needs by ensuring high quality products and the most professional services, Therefore, our products have been exported to almost the whole world and enjoyed a good reputation from our customer for years.

We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success.

Welcome everyone!

Taking "Sincerity makes trust, Quality wins market"as our business philosophy, Our company always put quality in the first place and meet our customers' needs by ensuring high quality products and the most professional services, Therefore, our products have been exported to almost the whole world and enjoyed a good reputation from our customer for years.

We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success.

Welcome everyone!

Our Services & Strength

1.Two years guarantee with all of our machines.

2.Full stainless steel material with this type of machines.

FAQ

1.Please tell me which kind of fruit do you want to core?

2.Do you want fruit washing cleaning processing machine line?

Hot Searches