- Product Details

- {{item.text}}

Quick Details

-

Production Speed(Cycles/min):

-

30

-

Air Pressure(MPa):

-

0.8 MPa

-

Sheet Thickness(mm):

-

0.2 - 1.6 mm

-

Heating Power (kW):

-

171 kW

-

Air Comsumption(L/min):

-

4200 L/min

-

Water Comsumption(L/min):

-

16.7 L/min

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

LITAI MACHINERY

-

Voltage:

-

custom made

-

Dimension(L*W*H):

-

L13000*W4300*H2800mm

-

Weight (T):

-

21 T

-

Power(KW):

-

246

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Machine Name:

-

Plastic Thermoforming Machine

-

PLC:

-

Touch screen control

-

Function:

-

Forming - Punching - Cutting - Stacking

-

Need to install several molds:

-

3 pairs

-

Application:

-

Plastic Products

-

feeding method:

-

automatic feeding

-

Accessories:

-

import

-

Keyword:

-

disposable food trays machine

-

Heating:

-

ceramic heating

Quick Details

-

Max.Forming Height(mm):

-

140 mm

-

Forming Width (mm):

-

820 mm

-

Forming Length (mm):

-

650 mm

-

Production Speed(Cycles/min):

-

30

-

Air Pressure(MPa):

-

0.8 MPa

-

Sheet Thickness(mm):

-

0.2 - 1.6 mm

-

Heating Power (kW):

-

171 kW

-

Air Comsumption(L/min):

-

4200 L/min

-

Water Comsumption(L/min):

-

16.7 L/min

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

LITAI MACHINERY

-

Voltage:

-

custom made

-

Dimension(L*W*H):

-

L13000*W4300*H2800mm

-

Weight (T):

-

21 T

-

Power(KW):

-

246

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Machine Name:

-

Plastic Thermoforming Machine

-

PLC:

-

Touch screen control

-

Function:

-

Forming - Punching - Cutting - Stacking

-

Need to install several molds:

-

3 pairs

-

Application:

-

Plastic Products

-

feeding method:

-

automatic feeding

-

Accessories:

-

import

-

Keyword:

-

disposable food trays machine

-

Heating:

-

ceramic heating

*Pictures and related technical parameters of products will be updated continuously without prior notice.The right of final

interpretation of this information belongs to our company.

interpretation of this information belongs to our company.

Product parameters

|

Technical Parameters

|

|

|

|

|||

|

Model

|

TTF-820AF

|

TTF-700AF

|

TTF-520AF

|

|||

|

Mould Size (Max.)

|

820*650mm

|

700*550 mm

|

520*400mm

|

|||

|

Forming Depth (Max.)

|

140mm

|

120mm

|

110mm

|

|||

|

Sheet thickness

|

0.2-1.6mm

|

|

|

|||

|

Forming Speed (Max.)

|

30times/min

|

|

|

|||

|

Air pressure

|

0.6-0.8mpa

|

|

|

|||

|

Air consumption

|

4.2m³/min

|

3.6m³/min

|

3.0m³/min

|

|||

|

Water consumption

|

1.0m³/h

|

0.7m³/h

|

|

|||

|

Sheet width (Max.)

|

850mm

|

730mm

|

550mm

|

|||

|

Suitable Sheet

|

PP, PS, HIPS, PET, PVC, PLA etc.

|

|

|

|||

|

Power supply

|

AC 380V, 50Hz, Three-phase, Four-wire

|

|

|

|||

|

Rated power

|

246Kw

|

211Kw

|

136Kw

|

|||

|

Heating power

|

171Kw

|

118Kw

|

75Kw

|

|||

|

Procedure

|

Forming-punching-cutting-stacking

|

|

|

|||

|

Dimension

|

L13000*W4300*H2800mm

|

L13000*W4500*H2800mm

|

L10800*W4650*H2670mm

|

|||

|

Weight

|

About 21.0T

|

About 25.0T

|

About 11.0T

|

|||

|

Main Electrical Components

|

|

|

|

|||

|

MODEL/PARTS

|

TTF-820A/AF

|

TTF-700A/AF

|

TTF-520A/AF

|

|||

|

Touch Screen

|

KUNLUN TONGTAI(CHINA)

|

|

DELTA(Taiwan)

|

|||

|

PLC

|

DELTA(Taiwan)

|

|

|

|||

|

Servo pack

|

DELTA(Taiwan)

|

|

|

|||

|

Servo Motor

|

DELTA(Taiwan)

|

|

|

|||

|

Forming valve

|

NORGREN(UK)

|

|

|

|||

|

Heater

|

ELSTEIN(Germany)

|

|

|

|||

|

Temperature control module

|

YUDIAN(CHINA)

|

|

ZHUOYUE(CHINA)

|

|||

|

Filter

|

CKD(Japan)

|

|

|

|||

|

Cylinder

|

KAOGEER(CHINA), AIR TAC(Taiwan)

|

|

|

|||

|

Solenoid Valve

|

JINQI, AIR TAC(Taiwan)

|

|

|

|||

|

Solid State Relay

|

FOTEK(Taiwan)

|

|

|

|||

|

Proximity Switch

|

FOTEK(Taiwan)

|

|

|

|||

|

Circuit Breaker

|

SCHNEIDER(France)

|

|

|

|||

|

AC Contactor

|

SCHNEIDER(France)

|

|

|

|||

|

Power switch

|

MEAN WELL(Taiwan)

|

|

|

|||

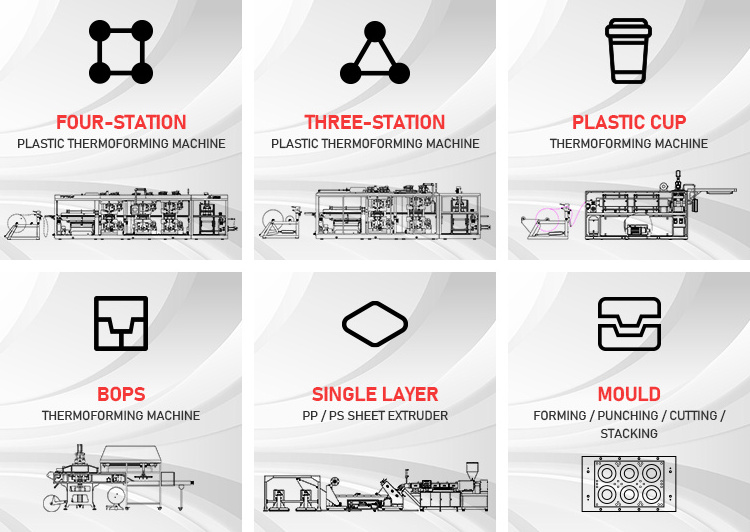

Products Description

APPLICATION

TTF series multi-step high-speed thermoforming machine is our latest developed product, which adopts big forming area and high efficiency drive type, which can be suit for most of the plastic products as customer requested. This machine adopts positive and negative pressure integrated thermoforming with Delta brand servo motor driven system and auxiliary stretching function to ensure the high precision in machine normal running and perfect performance on finished output products.

Main Function

1.positive and negative pressure forming device.2.vacuum forming device.

3.touch screen computer temperature module point to point control function.

4.air control device.

5.cooling device.

6.die, mold temperature control function.

7.automatic punching and cutting function.

8.automatic stack counting function.

9.edge automatic rewinding function.

10.safety protection device.

3.touch screen computer temperature module point to point control function.

4.air control device.

5.cooling device.

6.die, mold temperature control function.

7.automatic punching and cutting function.

8.automatic stack counting function.

9.edge automatic rewinding function.

10.safety protection device.

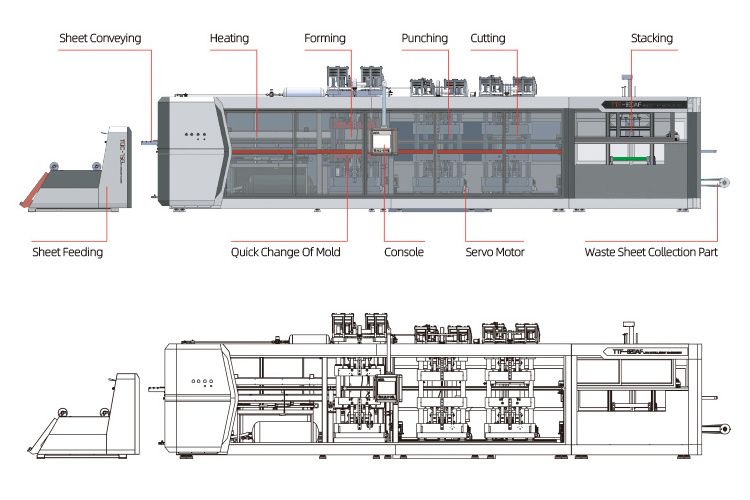

SUMMARY OF MACHINE

Feeding part

1. Load automatically, lower human resource cost.

2. Sheet conveying positively, lower the load of conveying servo motor.

3. Proximity switch clever control, getting the rid of falling down of the sheet by conveying too fast.

4. Double stations, big diameter, reduce the frequency of changing sheet coil, improve the the production efficiency.

Conveyor system

1. The guide rail of Aluminum is full of cooled water can cool the heated sheet efficiently leads to stable conveying.

2. Toothed chain with specialized degrees makes puncturing much easier, with specialized material- 65Mn makes it stronger and more durable.

3. Adjustable width and segmented chain , which is suitable for a wider range of sheet widths and solves the problem of sheet sagging caused by heating.

4. Driven by servo motor, accurate and efficient.

Heating part

1. Adopt Germany brand Elstein heating tile, excellent insulation performance and heating efficiency, which results in saving time and energy. (Increase speed by more than 50% and save energy by more than 30%). Based on this, the actual power consumption is about 30% of the rated power, it’s awesome and amazing.

2. Divided by two layers of the stove with optimized heating tile layout, makes the sheet heated fully and evenly.

3. The whole stove is divided into 44 separate temperature control units, the accuracy is controllable at 1 degree Cels to ensure that the sheet of each product is perfectly plasticized.

4. Covered with protective iron mesh to prevent the sheet from falling on the heating tile and causing a fire, be safe and reliable.

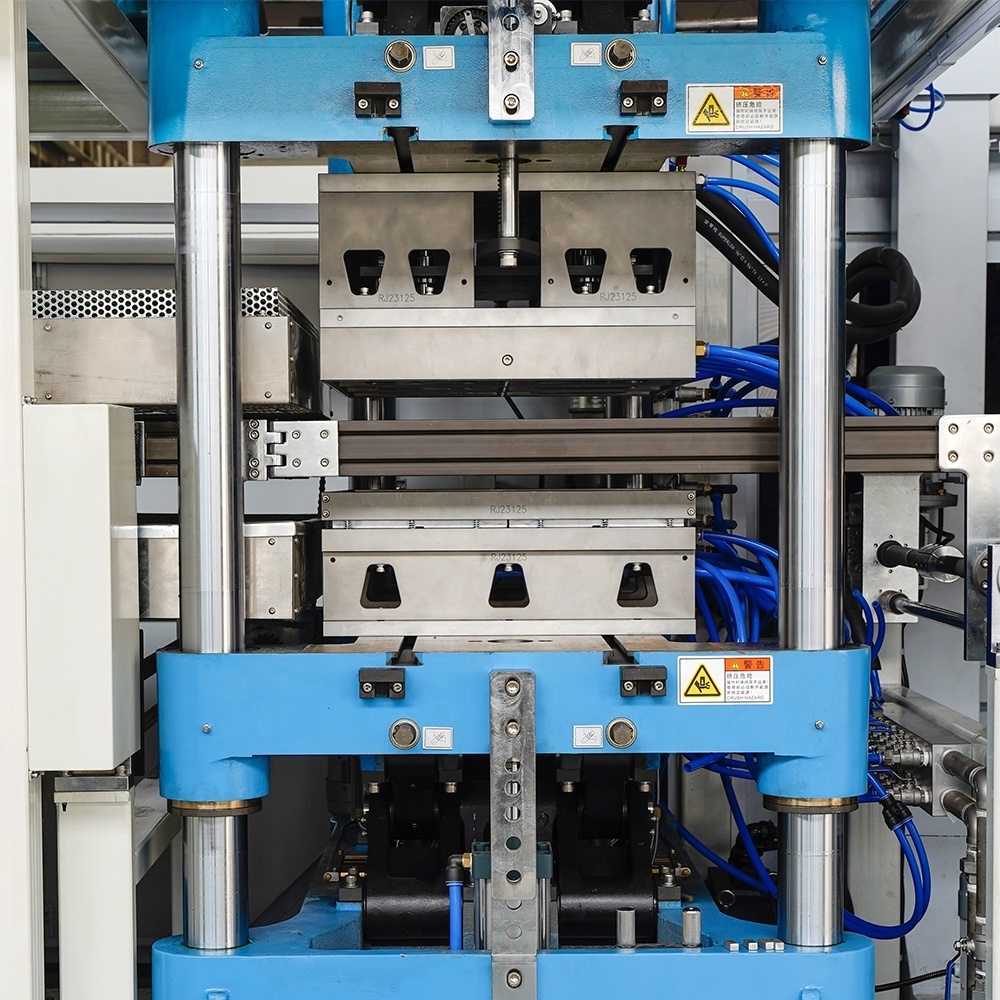

Forming station

1. Adopt the structure of four-pillars(40Cr steel) for supporting and uni-body mould plates (TQ-600 steel) for guiding, which make our forming station more stronger and stable, shock absorption and wear resisting.

2. Adopt eccentric wheel construction on the bottom, direct drive and low cost.

3. The parallelism misalignment between guide plate is less than 0.05mm,and for mould,less than 0.03mm,much lower than the industry average value.So our forming product size will be more precision, bottom will be more perfect.

4. Connection mechanism adopts wear resisting steel bushing, bears more weight, rotates more precise. And the symmetrical swing ensures the parallelism of machine running, to avoid four pillars transverse abrasion, and make the machine more long-life.

5. The assisting mechanism of changing mould, which is equipped with the sliding rail and supporting bar, to realize quick changing, save more time and labor.

6. Driven by high-power servo motor, super precision, high efficiency, and low noise.

7. Intelligent lubrication by a certain amount and time, so the machine can be long-life and sustainable.

8. The working theory is a combination of positive and negative pressure with assisting stretching in mould by some nylon plugs, which makes it have more powerful ability of making products.

9. The mould cavity has the cooling water inside, which expedites the cooling speed and makes it easy to demould.

10. The upper and lower station can adjust automatically, fast and more convenient.

11. we have four buffer cylinders on forming station, which reduces the shock of clamping, to ensure the smooth running of the sheet.

Forming station

1. Adopt the structure of four-pillars(40Cr steel) for supporting and uni-body mould plates (TQ-600 steel) for guiding, which make our forming station more stronger and stable, shock absorption and wear resisting.

2. The parallelism misalignment between guide plate is less than 0.05mm, and for mould, less than 0.03mm, much lower than the industry average value. it make the products cutting more accuracy and perfect.

3. The station can move up and down, right and left by automatic adjustment with anti-collision function, which make it easy and rapid to debug the mould.

4. The mould blade is heated by the heating guide plate, which makes the product easy to cut, and the edge is more perfect.

5. The overheating alarm function (90°C) on the heating guide plate , which is safe and reliable.

6. High-power servo motor, has powerful cutting force, that the cutting line can reach 12 meters, to ensure cutting perfect.

7. The movable blade has a positioning guide function, which makes the product cutting more accurate.

8. The intelligent lubrication system can lubricate by a certain amount and time, which can make the machine longevity and sustainability.

9. The assisting mechanism of changing mould, which is equipped with the sliding rail and supporting bar, to realize quick changing, save more time and labor.

10. we have four buffer cylinders on cutting station, which reduces the shock of clamping, to ensure the precision of product cutting.

11. Adopt eccentric wheel construction aside, visible running, easy maintenance.

12. Connection mechanism adopts wear resisting steel bushing, bears more weight, rotates more precise. And the

symmetrical swing ensures the parallelism of machine running, to avoid four pillars transverse abrasion, and make the machine more long-life.

symmetrical swing ensures the parallelism of machine running, to avoid four pillars transverse abrasion, and make the machine more long-life.

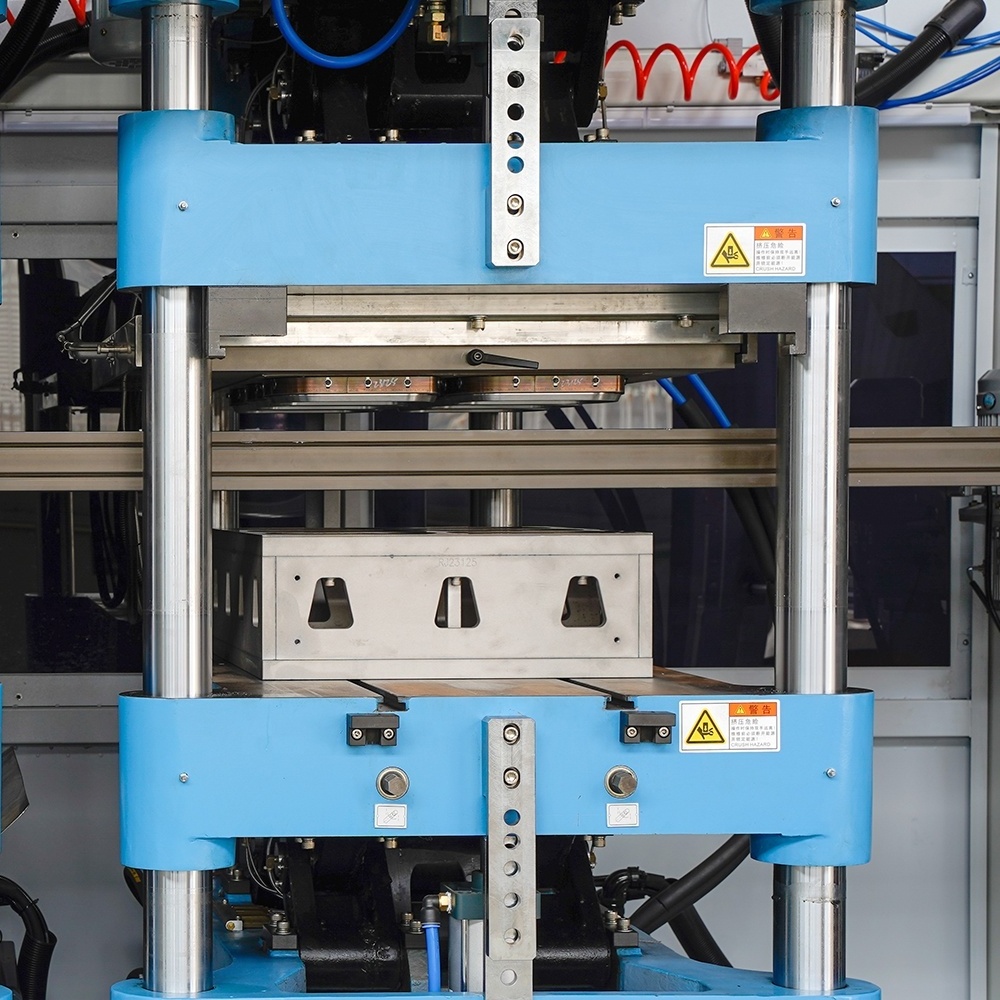

Cutting station

1. Adopt the structure of four-pillars(40Cr steel) for supporting and uni-body mould plates (TQ-600 steel) for guiding, which make our forming station more stronger and stable, shock absorption and wear resisting.

2. The parallelism misalignment between guide plate is less than 0.05mm, and for mould, less than 0.03mm, much lower than the industry average value. It make the products cutting more accuracy and perfect.

3. The station can move up and down, right and left by automatic adjustment with anti-collision function, which make it easy and rapid to debug the mould.

4. The mould blade is heated by the heating guide plate, which makes the product easy to cut, and the edge is more perfect.

5. The overheating alarm function (90°C) on the heating guide plate , which is safe and reliable.

6. High-power servo motor, has powerful cutting force, that the cutting line can reach 12 meters, to ensure cutting perfect.

7. The movable blade has a positioning guide function, which makes the product cutting more accurate.

8. The intelligent lubrication system can lubricate by a certain amount and time, which can make the machine longevity and sustainability.

9. The assisting mechanism of changing mould, which is equipped with the sliding rail and supporting bar, to realize quick changing, save more time and labor.

10. we have four buffer cylinders on cutting station, which reduces the shock of clamping, to ensure the precision of product cutting.

11. Adopt eccentric wheel construction on the bottom, direct drive and low cost.

12. Connection mechanism adopts wear resisting steel bushing, bears more weight, rotates more precise. And the symmetrical swing ensures the parallelism of machine running, to avoid four pillars transverse abrasion, and make the machine more long-life.

Stacking station

1. Adopt the push down stacking type, it's economic to meet the requirements of most products.

2. Stacking is driven by servo motor, makes more precise and efficient.

3. Equipped with removable and replaceable conveying belt, efficient and convenient.

4. Replaceable suck rod device, to meet the needs of different products.

5. Equipped with multiple muffler devices to reduce stacking noise.

6. Aluminum suck rod, light and durable.

Touch screen PLC

1. Friendly interactive interface,it is easy to operate.

2. Large memory, to meet the requirements of huge product data storage.

3. The product data is stored and read through one key function, easy operation.

4. The movable touch screen makes the operation flexible and convenient.

5. High integration, data visualization, easy to control.

What is features and advantages of our plastic thermoforming machine?

1. Fully servo driven machine.no noise.no vibration,thermoforming good and fast.

2. Fully machine in compact structure,taking small floor space;

3. Can be adapted to a variety of materials,and the products thicker 8% than the average machine products.

4. Furnaces automatic removal device,can be turned down at any time during production without breaking the sheet reaching without wasting materials;

5. Electric furnace temperature control system uses intelligent automatic compensation control,a control,a control of a regulator,easy to adjust the temperature uniformity,easy to use,simple,fast heating,low temperature three times up and down the oven roast slices.

6. Forming,cutting die servo-driven,two-way adjustable for upper and lower mold stroke,in which the upper mold electric adjustable in clamping direction. The upper and bwer molds height position can be adjusted conveniently and fast under the clamping state;lower mold in clamping direction readily accessible buffer,increasing the clamping speed,avoiding shock.

7. Auto cutting,auto counting,auto transmission by PLC.

8. Labor saving,only 1-2 workers packing.

Contact Us

Facebook

https://pse.is/3urql5

LinkedIn

https://pse.is/3ythvl

YouTube

https://pse.is/3zkhvj

Tiwtter

https://pse.is/3z675l

Instagram

https://pse.is/3yhe6m

Pinterest

https://pse.is/3vd57m

Official website

http://www.litai.cc/

Tik Tok

http://pesc.pw/478rpe

Made in China

https://pse.is/3rh2nv

Hot Searches