- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/220V

-

Dimension(L*W*H):

-

100X45X85CM

-

Motor Power (Kw):

-

7.5kw-200kw

-

Power (kW):

-

7.5kw-200kw

-

Weight (KG):

-

437 KG

-

Product name:

-

Biomass Waste Sawdust Pellet Mill Wood Pellet Machin

-

Raw material:

-

Alfalfa\Sawdust\straw\rice Husk\wood Waste

-

Application:

-

Farms, Home Use, Fuel Factory, Energy & Mining, Making wood pellets

-

Pellet size:

-

6/8/10/12mm Customized

-

Ideal moisture:

-

Biomass Pellet 10-15%

-

Keywords:

-

Wood Branch Sawdust Wood Pellets Machine Maker Wood Pellet Mill

-

Machine name:

-

Wood Granulator Machine Biomass Wood Pellet

-

Machine type:

-

Biomass Fuel Wood Pellet Machine

-

Warranty peroid:

-

One year

Quick Details

-

Pellet Diameter (mm):

-

4 - 12

-

Output (kg/h):

-

100 - 4000 kg/h

-

Place of Origin:

-

Henan, China

-

Voltage:

-

380V/220V

-

Dimension(L*W*H):

-

100X45X85CM

-

Motor Power (Kw):

-

7.5kw-200kw

-

Power (kW):

-

7.5kw-200kw

-

Weight (KG):

-

437 KG

-

Product name:

-

Biomass Waste Sawdust Pellet Mill Wood Pellet Machin

-

Raw material:

-

Alfalfa\Sawdust\straw\rice Husk\wood Waste

-

Application:

-

Farms, Home Use, Fuel Factory, Energy & Mining, Making wood pellets

-

Pellet size:

-

6/8/10/12mm Customized

-

Ideal moisture:

-

Biomass Pellet 10-15%

-

Keywords:

-

Wood Branch Sawdust Wood Pellets Machine Maker Wood Pellet Mill

-

Machine name:

-

Wood Granulator Machine Biomass Wood Pellet

-

Machine type:

-

Biomass Fuel Wood Pellet Machine

-

Warranty peroid:

-

One year

Product Description

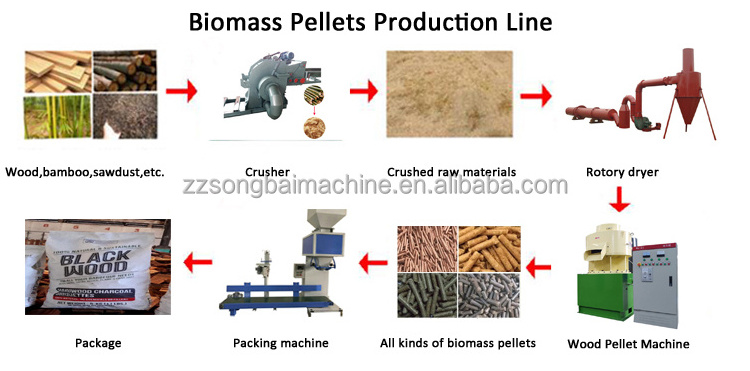

The introduction of Biomass Wood Pellet Mill

Our wood pellet machine is a mature energy saving equipment. This kind of wood pellet mill is easy to operate and maintain with lower price. The finished pellets is biofuel of biomass energy, which can replace coal, oil, gas, etc., widely used in power plant, boiler, and heating system. Its hardness is closely to European standard. Pellet fuel is convenient in the process of manufacturing, packing, storing and transporting as a clean renewable energy.

This machine take full advantage of waste material such as wood, sawdust, wood chips, straw, rice husk, peanut shell, etc. help you save money, make money and good for environmental.

Our wood pellet machine is a mature energy saving equipment. This kind of wood pellet mill is easy to operate and maintain with lower price. The finished pellets is biofuel of biomass energy, which can replace coal, oil, gas, etc., widely used in power plant, boiler, and heating system. Its hardness is closely to European standard. Pellet fuel is convenient in the process of manufacturing, packing, storing and transporting as a clean renewable energy.

This machine take full advantage of waste material such as wood, sawdust, wood chips, straw, rice husk, peanut shell, etc. help you save money, make money and good for environmental.

Specification

According the different pellets production, we have many models for the wood pellet mill, you can check the below specification to check which model you prefer to , if you have any interest, you can contact us freely, we glad to provide more professional recommend to you.

The Home Used of Wood Pellet Machine

Mainly used for home and small process plant, It is mainly used for Wood, Straw, Cotton stalk, Rice husk, Peanut shell, Bamboo, Empty fruit branch, Pulverized coal and waste paper etc. Advantages of out products is high density, high fuel value, low moisture and low ash content, machines running by reduction gears. Details as follows:

Mainly used for home and small process plant, It is mainly used for Wood, Straw, Cotton stalk, Rice husk, Peanut shell, Bamboo, Empty fruit branch, Pulverized coal and waste paper etc. Advantages of out products is high density, high fuel value, low moisture and low ash content, machines running by reduction gears. Details as follows:

|

Model

|

Power rating-KW

|

Capacity-KG/H

|

Product size-CM

|

Weight-KG

|

|

SKJ200

|

7.5

|

100-150

|

100X45X85

|

260

|

|

SKJ250

|

15

|

200-250

|

120X55X105

|

550

|

|

SKJ300

|

22

|

250-300

|

125X60X110

|

590

|

The Industrial (Commercial) Used of Wood Pellet Machine

Suitable used for the small pellet production line or industrial pellet plant.

We also have big capacity wood pellet machine from 55KW to 200KW for Industrial( Commercial) application wood pellet production.

If the capacity you wanted is bigger than 800kg/h, we are recommend our Vertical ring die pellet mill to you. Details as follows:

Suitable used for the small pellet production line or industrial pellet plant.

We also have big capacity wood pellet machine from 55KW to 200KW for Industrial( Commercial) application wood pellet production.

If the capacity you wanted is bigger than 800kg/h, we are recommend our Vertical ring die pellet mill to you. Details as follows:

|

Model

|

Power rating-KW

|

Capacity-KG/H

|

Product size-CM

|

Weight-KG

|

|

SKJ350

|

30

|

400-500

|

135X80X130

|

1000

|

|

SKJ450

|

37

|

600-700

|

130X70X150

|

1450

|

|

SKJ500

|

55

|

800-1200

|

140X75X155

|

2200

|

|

SKJ550

|

90

|

1500-2000

|

190X95X180

|

4000

|

|

SKJ800

|

160

|

2000-3000

|

250X135X210

|

6500

|

|

SKJ1000

|

200

|

3000-4000

|

265X145X210

|

8000

|

Our wood pellet machine with the automatic lubricating system and the cooling and dedusting system

1. Automatic lubricating system can be used to ensure continue working in 24 hours per day.

--Automatic lubricating system for gear box

--Automatic lubricating system for rollers

2.Cooling and dedusting system:

--Reduce the temperature of wood pellet machine's working space, the wood pellet machine will working more stable.

--Remove the dust and water vapour, ensure the good quality of final pellets with low moisture.

--Greatly improve working environment for workers.

1. Automatic lubricating system can be used to ensure continue working in 24 hours per day.

--Automatic lubricating system for gear box

--Automatic lubricating system for rollers

2.Cooling and dedusting system:

--Reduce the temperature of wood pellet machine's working space, the wood pellet machine will working more stable.

--Remove the dust and water vapour, ensure the good quality of final pellets with low moisture.

--Greatly improve working environment for workers.

Product Application

The Development Prospect Of The Biofuel Pellet Production

Wood pellets as a fuel have many economic and ecological advantages over coal, gas and fuel oil. The price of pellets develops largely independently of gas and oil prices, which will continue to rise as resources become scarcer and eco-taxes increase.

Pellets are already a cost-effective alternative to fossil fuels in terms of the fuel price. In addition, jobs are being created

in regions with a lot of wood and forestry.

Environmental pollution as a result of tanker accidents and leaks in gas pipelines does not occur when using pellets as fuel. The risk of explosions, fires and groundwater contamination when storing the fuel is also significantly lower compared to fossil fuels.

Wood pellets are standardized, cylindrical compacts made from dried, natural residual wood with a diameter of approx. 4 - 10 mm and a length of 20 - 45 mm. So-called sawmill by-products such as sawdust or wood shavings are used for production. They are manufactured under high pressure without the addition of chemical binders and have a calorific value of around 5 kWh/kg. This means that the energy content of one kilogram of pellets roughly corresponds to that of half a liter of heating oil.

Wood pellets as a fuel have many economic and ecological advantages over coal, gas and fuel oil. The price of pellets develops largely independently of gas and oil prices, which will continue to rise as resources become scarcer and eco-taxes increase.

Pellets are already a cost-effective alternative to fossil fuels in terms of the fuel price. In addition, jobs are being created

in regions with a lot of wood and forestry.

Environmental pollution as a result of tanker accidents and leaks in gas pipelines does not occur when using pellets as fuel. The risk of explosions, fires and groundwater contamination when storing the fuel is also significantly lower compared to fossil fuels.

Wood pellets are standardized, cylindrical compacts made from dried, natural residual wood with a diameter of approx. 4 - 10 mm and a length of 20 - 45 mm. So-called sawmill by-products such as sawdust or wood shavings are used for production. They are manufactured under high pressure without the addition of chemical binders and have a calorific value of around 5 kWh/kg. This means that the energy content of one kilogram of pellets roughly corresponds to that of half a liter of heating oil.

Packing & Delivery

We provide different shipping methods per customers' requests: By sea/By train/By truck/By air

All machines are packed by wooden case which can protect machines very well.

You do not worry about any damages during the transportation.

For LCL order, we can send machines to port or any other places in China.

For FCL order, we can ask the containers to come to our factory for loading.

All machines are packed by wooden case which can protect machines very well.

You do not worry about any damages during the transportation.

For LCL order, we can send machines to port or any other places in China.

For FCL order, we can ask the containers to come to our factory for loading.

Hot Searches