- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220-440V

-

Power:

-

220kw

-

Warranty:

-

12 Months

-

Dryer:

-

one drying layers

-

Forming Type:

-

Rotary

-

Power Requirement:

-

200KW-300KW

-

Automation:

-

Fully Automatic

-

Processing Material:

-

Waste Paper / used newspaper / waste carton

-

Worker requirement:

-

5-6 persons

-

Workshop requirement:

-

800m^2

-

Capacity:

-

6000pieces/ hour

-

Production:

-

Egg Tray, Egg carton, Fruit Tray, Cup Carrier,Medical Care Product

-

Fuel:

-

Diesel, Heavy oil, LPG, Natural Gas, Coal, Wood, Steam

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

NANYA

-

Model Number:

-

ER6000A

-

Voltage:

-

220-440V

-

Power:

-

220kw

-

Warranty:

-

12 Months

-

Dryer:

-

one drying layers

-

Forming Type:

-

Rotary

-

Power Requirement:

-

200KW-300KW

-

Automation:

-

Fully Automatic

-

Processing Material:

-

Waste Paper / used newspaper / waste carton

-

Worker requirement:

-

5-6 persons

-

Workshop requirement:

-

800m^2

-

Capacity:

-

6000pieces/ hour

-

Production:

-

Egg Tray, Egg carton, Fruit Tray, Cup Carrier,Medical Care Product

-

Fuel:

-

Diesel, Heavy oil, LPG, Natural Gas, Coal, Wood, Steam

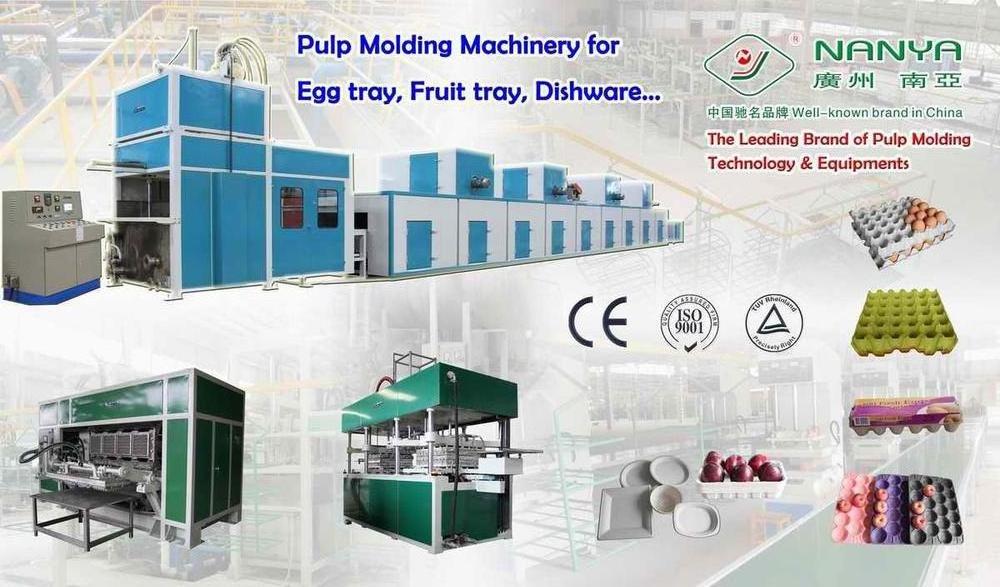

egg tray pulp molding machine egg tray machine good price egg packing machinery

This type of production line is constituted by a hydrapulper system, a rotary type forming machine, a multiple-layer drying line, and corollary equipment . The raw material is recycled paper such as newspaper,white paper,carton box . It’s environmental, high-efficiency, energy-saving, durable, and easy to operate. To invest this machine, can help you gain more.

International supplier

Product Description

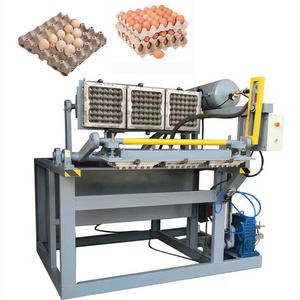

- It’s a fully automatic egg tray production line

- Mainly used for the products with simple structure but in big quantity, such as egg trays, egg carton, fruit trays, cup carriers and disposable medical care products.

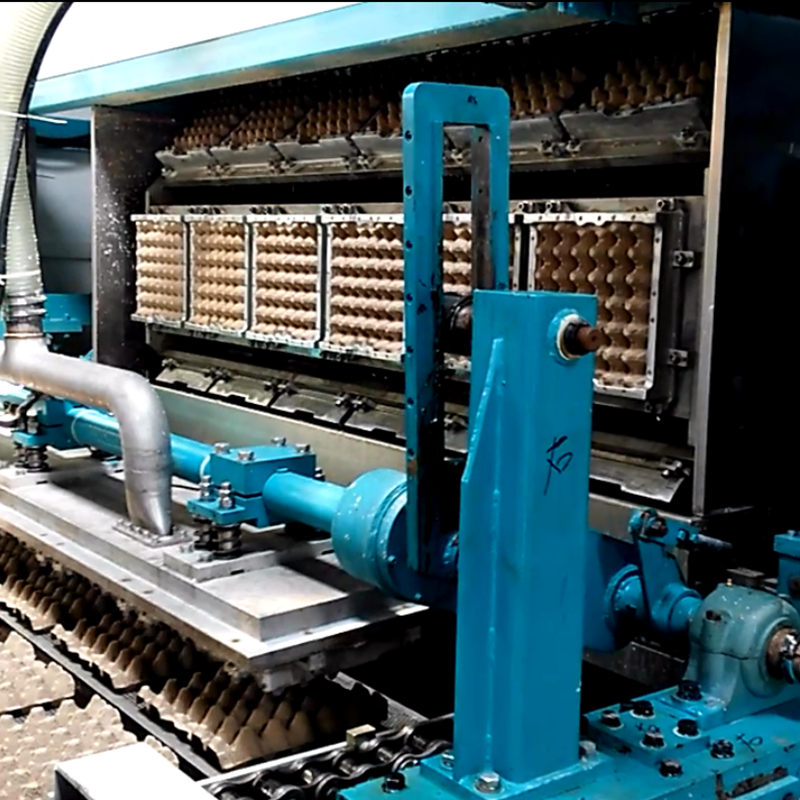

- This type of production line is constituted by a hydrapulper system, a rotary type forming machine, a six layers drying line, and corollary equipments.

- Products are produced automatically from waster paper or other type of paper. It’s high-efficiency, energy-saving, durable, wieldy and safe.

- SIEMENS electrical control parts, FESTO & SMC pneumatic control parts. Apply International famous brand of control parts to obtain excellent performance and universality maintainability.

Pr ocess of the machine

Working Theory:

This type of egg tray consists of a hydrapulper system, a rotary forming machine, a multiple layers drying line

and corollary equipments .

The raw material is recycled paper such as used newspaper, waste carton, off-cut in papermaking mill and printing factories.These raw material can be collected at low cost and are environmental friendly.

First, the workers weight the raw material and put them into the conveyor which sends the raw material to the hydrapulper. Then the raw material will be smashed and mixed to a certain consistency. Then the processes of forming, drying and stacking will be finished automatically. The products can get more smooth and compact after the hot-pressing process.

This machine also can produce egg carton, egg box and fruit trays and ect as long as the moulds are changed.

There is no waste water or exhaust gas emission duiring the whole production process, Besides, the water can be used circularly, and the used pulp molding products can also recycled. In this way, the production line would never pollute the earth, get great productivity with least cost.

Specification

|

Model Type |

ER6000-A |

|

Capacity |

6000 pcs/hour |

|

Workshop Requirement |

800 m 2 |

|

Electricity Consumption |

~220 kw |

|

Electricity Installed |

360 kw |

|

Material Consumption |

360~400 kg/h |

|

Water Consumption |

1200~1400 kg/h |

|

Worker Requirement |

5~6 persons |

|

Container Requirement for Shipment |

9 x 40 HQ |

|

Forming Machine (Rotary Type) |

Rotary type with 8 plates. Each for 6 pcs / time |

|

Drying Line |

42x3.4x3.6 m

|

|

Remarks:

|

|

Fuel Consumption (One Item Selectable)

|

Natural gas |

110~120 m 3 /h |

|

LPG |

40~45 m 3 /h |

|

Diesel |

95~100 kg/h |

|

Heavy Oil |

98~105 kg/h |

|

Steam |

1.9~2.2 ton/h |

|

Wood |

400~450 kg/h |

|

Coal |

260~300 kg/h |

Applications

D etail

Comprehensive strength