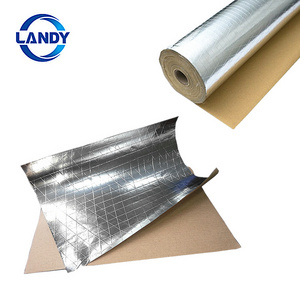

Jinan United Perfect Building Materials Corporation have the special formula can supply the fire retardant foillamination products

to the HAVC industries, the flame retardant and smoke performance aiso pass theBS476 and ASTM testing

- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Warehouse

-

Design Style:

-

Industrial

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Perfect

-

Model Number:

-

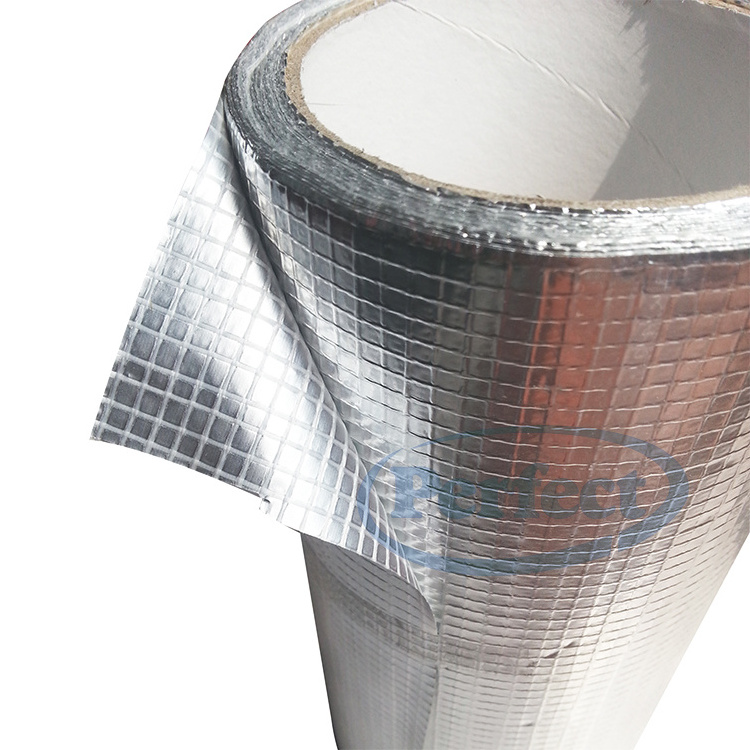

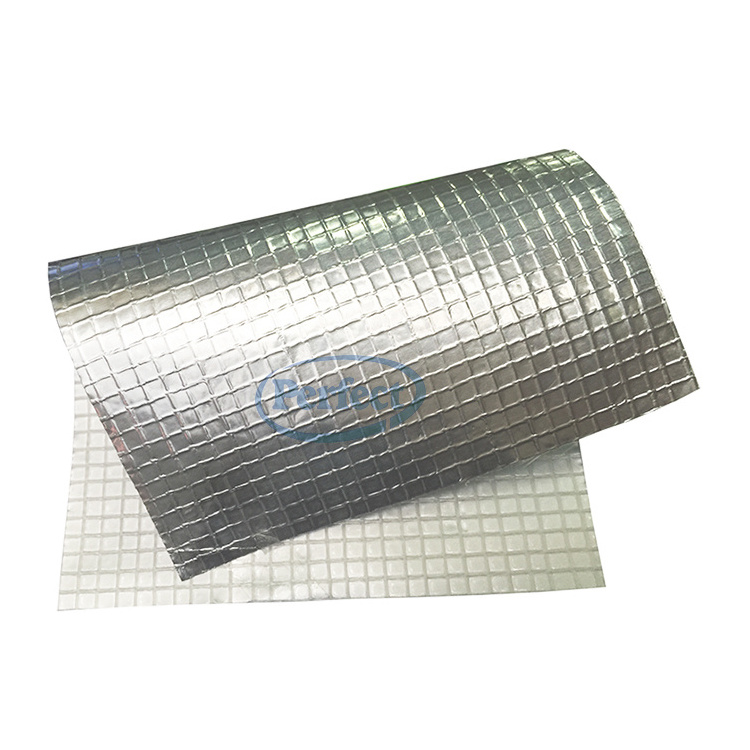

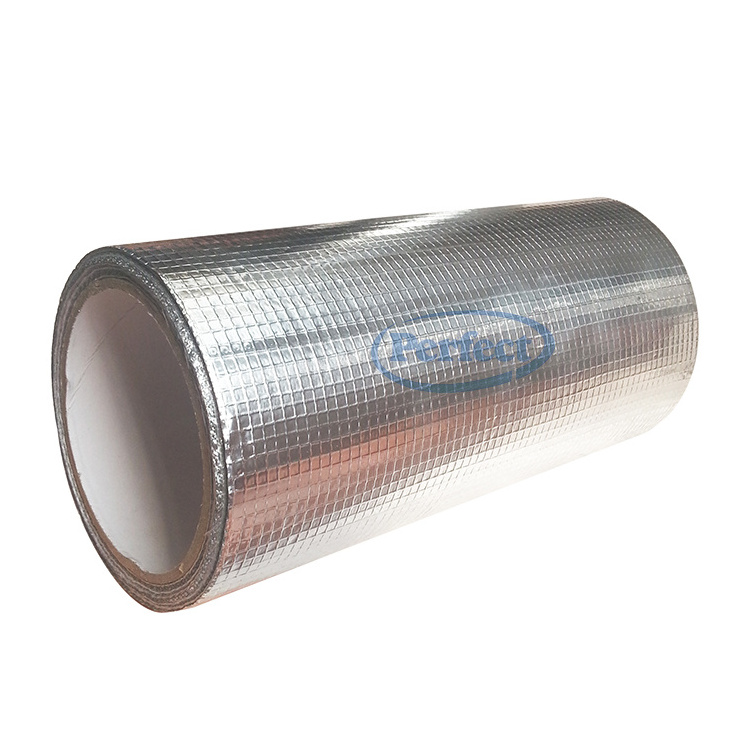

Foil-scrim-PE

-

Type:

-

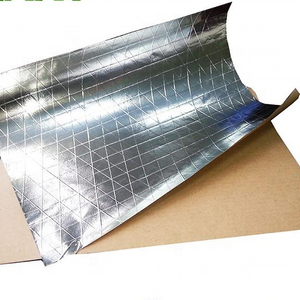

lamination foils, Other heat insulation

-

Material:

-

aluminum

-

Product Name:

-

lamination foils

-

Usage:

-

Metal Roof Sarking-

-

Raw material:

-

aluminum scrim kraft paper

-

Width:

-

1/1.2/1.25/customized

-

Length:

-

60-4500M

-

Basis Weight:

-

75g--450g

-

Certificate:

-

ASTM E84

-

OEM:

-

accepted

-

Sample:

-

welcome accepted

Quick Details

-

Warranty:

-

5 years

-

After-sale Service:

-

Online technical support, Onsite Installation, Onsite Training, Onsite Inspection, Free spare parts, Return and Replacement

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation

-

Application:

-

Warehouse

-

Design Style:

-

Industrial

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Perfect

-

Model Number:

-

Foil-scrim-PE

-

Type:

-

lamination foils, Other heat insulation

-

Material:

-

aluminum

-

Product Name:

-

lamination foils

-

Usage:

-

Metal Roof Sarking-

-

Raw material:

-

aluminum scrim kraft paper

-

Width:

-

1/1.2/1.25/customized

-

Length:

-

60-4500M

-

Basis Weight:

-

75g--450g

-

Certificate:

-

ASTM E84

-

OEM:

-

accepted

-

Sample:

-

welcome accepted

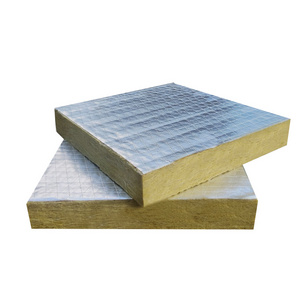

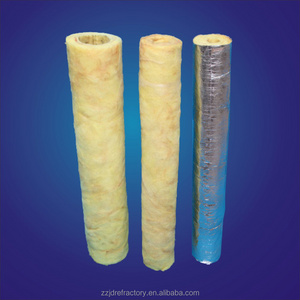

Heavy Duty fire isolation foil face aluminium Thermal Insulation Reflective foil faced fiberglass mineral wool insulation

Reflects 96% at least of radiant heat

Non-toxic/Non-allergic.

Easy to cut and install

Easy to cut and install

Durable and lightweight

Does not compress, collapse or disintegrate

Not affected by moisture or humidity

Permanent and maintenance-free

Aluminium Foil Facings for Metal Building Roofing Insulation

Jinan United Perfect Building Materials is the professional manufacture on roofing insulation foil facingsPerfect's foil facings

focus on the vapor retarders & reflective heat performance, protect the indoortemperature are stable. Our facings take the special

formula up to the standard of fire retardant

focus on the vapor retarders & reflective heat performance, protect the indoortemperature are stable. Our facings take the special

formula up to the standard of fire retardant

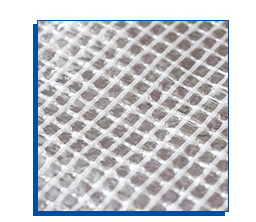

Foil Facings Used for Rockwool, Glasswool,Rubber factories etc

Jinan United Perfect Building Materials Corporation supply various kind of foil facings to many famousrockwool, glasswool,

rubberfoam, ceramic fiber factories in the world. Perfect with the enought productionlines can satificate customer's diffirent

request, also OEM for many competitiors.

rubberfoam, ceramic fiber factories in the world. Perfect with the enought productionlines can satificate customer's diffirent

request, also OEM for many competitiors.

Q WHAT LAMINATION WAYS DO YOU USE?

A: We have plastic extrusion, glue laminations with our accurate machines & professional technics to control the good quality. The lamination way is according to customer's requirement or our rich experience.

Q CAN I ORDER PERFORATED & PRINTED PRODUCTS?

A: Yes, PERFECT can perforate its full line of insulation facings & arrange printing for foils. Perforations are available in the following options: Full coverage where 100% of the exposed surface is pin perforated. This is designed for application where the facing is typically not laminated to the fiberglass. Pattern or "Channel" perforated to allow for easy laminating. This technique allows the facing to be laminated to fiberglass with no adhesive bleed through.

Q WHAT IS THE MAXIMUM INDOOR HUMIDITY THAT AVOIDS MOISTURE PROBLEMS?

A: The maximum recommended continuous indoor relative humidity (RH) varies from 30% to 45%, depending on geographic location.

General guidelines by region of the country can be found here. An engineer should be consulted to determine the correct HVAC design for a specific facility.

Q WHAT HAPPENS WHEN A FACING BECOMES WET AFTER INSTALLATION?

A: Typically, insulation facing will not be affected by limited exposure to water if allowed to fully dry. Prolonged exposure to water can potentially result in a loss of certain physical properties.

Q WHY DO YOU OCCASIONALLY EXPERIENCE STAINING OF FOIL FACED INSULATION?

A: Improperly ventilated bags are the primary cause of staining. Black or brown staining is caused by extended exposure to moisture on the surface of the foil. Potential sources of moisture are: Adhesive used to laminate the facing to fiberglass,Improper job site storage, Exposure to curing concrete, Daytime/nighttime temperature changes

A: We have plastic extrusion, glue laminations with our accurate machines & professional technics to control the good quality. The lamination way is according to customer's requirement or our rich experience.

Q CAN I ORDER PERFORATED & PRINTED PRODUCTS?

A: Yes, PERFECT can perforate its full line of insulation facings & arrange printing for foils. Perforations are available in the following options: Full coverage where 100% of the exposed surface is pin perforated. This is designed for application where the facing is typically not laminated to the fiberglass. Pattern or "Channel" perforated to allow for easy laminating. This technique allows the facing to be laminated to fiberglass with no adhesive bleed through.

Q WHAT IS THE MAXIMUM INDOOR HUMIDITY THAT AVOIDS MOISTURE PROBLEMS?

A: The maximum recommended continuous indoor relative humidity (RH) varies from 30% to 45%, depending on geographic location.

General guidelines by region of the country can be found here. An engineer should be consulted to determine the correct HVAC design for a specific facility.

Q WHAT HAPPENS WHEN A FACING BECOMES WET AFTER INSTALLATION?

A: Typically, insulation facing will not be affected by limited exposure to water if allowed to fully dry. Prolonged exposure to water can potentially result in a loss of certain physical properties.

Q WHY DO YOU OCCASIONALLY EXPERIENCE STAINING OF FOIL FACED INSULATION?

A: Improperly ventilated bags are the primary cause of staining. Black or brown staining is caused by extended exposure to moisture on the surface of the foil. Potential sources of moisture are: Adhesive used to laminate the facing to fiberglass,Improper job site storage, Exposure to curing concrete, Daytime/nighttime temperature changes

Hot Searches