- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

≤ 1%

-

Packaging Type:

-

Syringe

-

Voltage:

-

110V, 220V, 240V, 380V, 400V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Rongjun

-

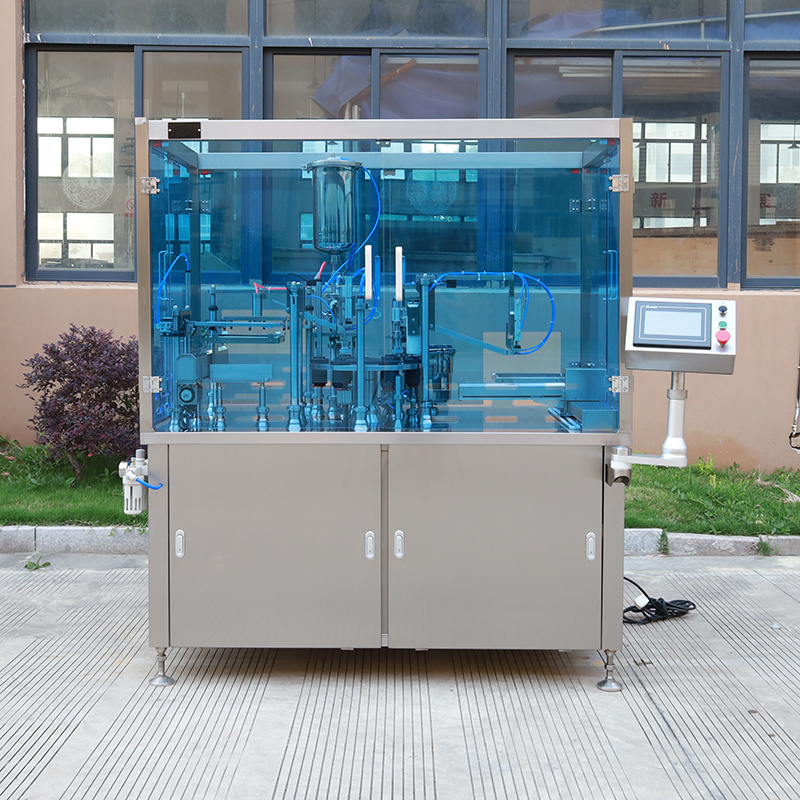

Dimension(L*W*H):

-

1200L x 800Wx 1800H(mm)

-

Weight:

-

850 KG

-

Material:

-

Stainless Steel 304/316L

-

Equipment Name:

-

Syringe Filler Closing machine Pre-filled Capping Sealing machine

-

Machine Name:

-

Syringe Plugging Machine; Hyaluronic Acid Prefilled Machine

-

Certification:

-

Certified by ITS, TUV, CE, ISO 9001

Quick Details

-

Machinery Capacity:

-

2000BPH

-

Packaging Material:

-

Plastic, Glass

-

Filling Material:

-

liquid

-

Filling Accuracy:

-

≤ 1%

-

Packaging Type:

-

Syringe

-

Voltage:

-

110V, 220V, 240V, 380V, 400V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Rongjun

-

Dimension(L*W*H):

-

1200L x 800Wx 1800H(mm)

-

Weight:

-

850 KG

-

Material:

-

Stainless Steel 304/316L

-

Equipment Name:

-

Syringe Filler Closing machine Pre-filled Capping Sealing machine

-

Machine Name:

-

Syringe Plugging Machine; Hyaluronic Acid Prefilled Machine

-

Certification:

-

Certified by ITS, TUV, CE, ISO 9001

Products Description

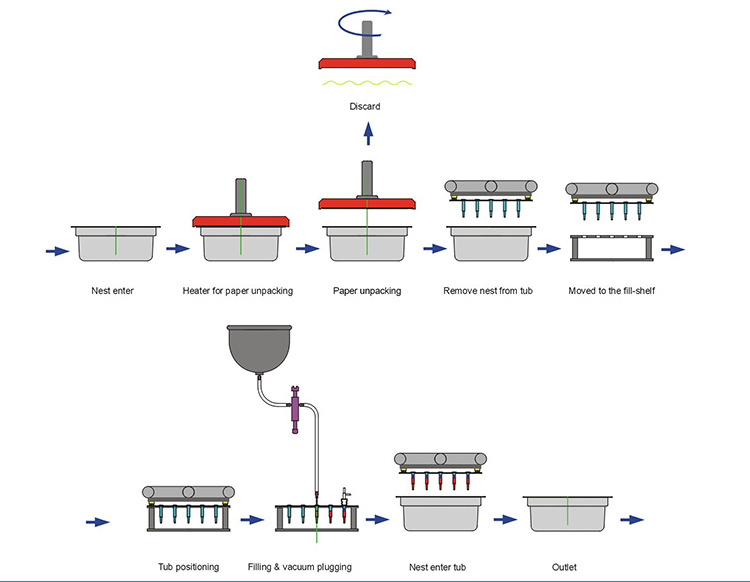

Injection syringe assembly machine is our company developed on the basis of market demand and combined with our technical advantages. After a lot of research on various pre-filled syringe assembly process, we independently developed and produced a fully independent intellectual property product. This machine is widely used in various specifications of pre-filled syringe assembly, such as the above-mentioned components and assembly, filling and sealing, and clamping.

Characteristics and advantages:

This machine is suitable for the above-mentioned components and assembly, filling and sealing, and clamping of syringes.

The machine uses machine-electric integrated technology, and all its main functions are controlled by servo motors. Accurate and reliable, long service life.

The electric control part uses PLC programmable controller, and the control program is stable and reliable.

The control panel is a touch screen all-in-one machine, with a simple and clear interface.

All detection parts use high-precision sensors for fine monitoring, and stoppage occurs when there is no pipe, no cap, and stops the operation of the machine to ensure that no problems occur.

The work of all pipes and stoppers is automated, which greatly improves efficiency and speed.

The machine complies with the requirements of sterile grade and GMP standard, and all the products are designed with various safety protections, such as:

Overload and current automatic stop of motor protection;

Leakage current automatic cutoff to avoid personal and machine damage;

Various protections have alarm prompts, and the operator can know the cause of the fault according to the prompts.

Packing type

Our Advantages

|

Certification

|

18 National Patents, Audited by SGS/TUV/CE/ISO9001

|

|

Quality Guarantee

|

Complaint rate as low as 5‰ for 15 years. If you decide to purchase from us, any malfunction happened, once you enquiry us, we will reply you solution within 48 hours except the special reasons

|

|

Short Lead Time

|

Lead time is flexible. Short turnaround of replacement parts made by substantial storage, Normally we are 20% faster than others. If you have urgent orders, pls feel free to contact us. We will get the job done with 100% satisfaction.

|

|

24/7 Available

|

All your inquiry will be responded within 1 hour. All your quotation will be satisfied within 12 hours.

|

|

Why choose us?

|

•100% manufacturer

• Rich production experience

•Strict Quality Control System

•Flexible MOQ

•Punctual delivery

•Excellent and Experienced Team

|

Hot Searches