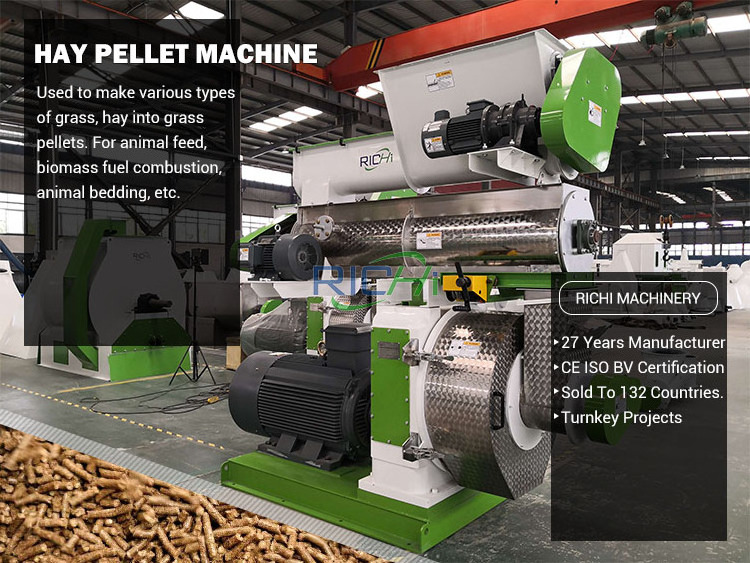

RICHI MLZH-Series

Alfalfa Hay Pellet Machine

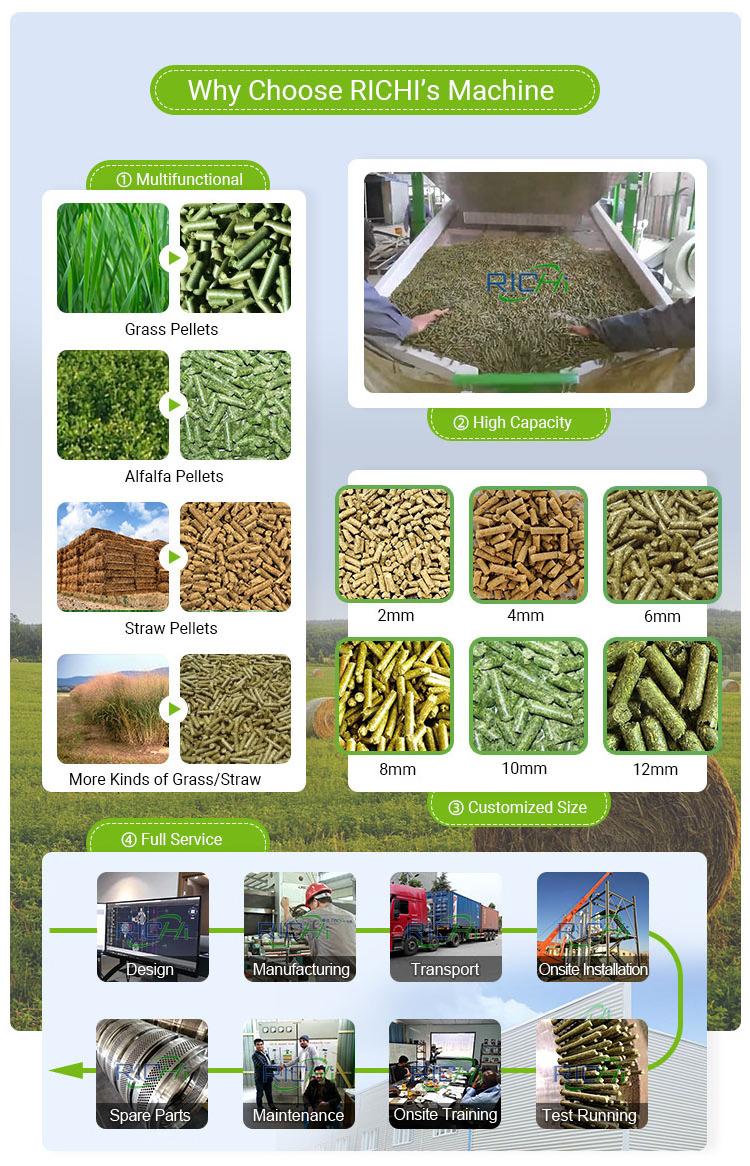

can make grass, straw, pasture, alfalfa, etc into 6~12mm or other size grass pellets.

Grass pellets have a variety of uses such as: as animal c

attle, sheep and horses

feed, as biofuel biomass pellet,

as horse bed

etc.

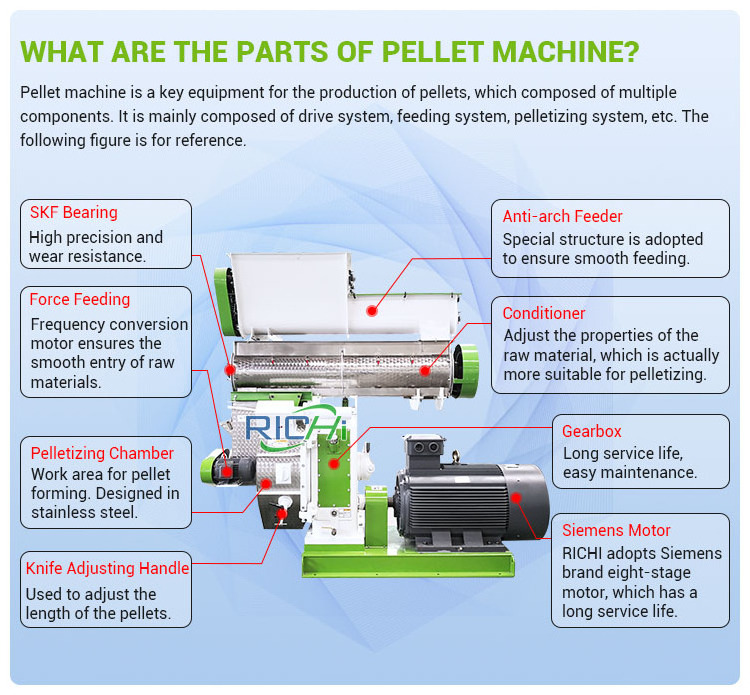

The core parts of the machine, the ring die and pressure roller are made of stainless steel, which is more wear-resistant and has a long service life. The motor adopts Siemens motor with low failure rate.