- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V+380V

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

K Snow

-

Dimension(L*W*H):

-

364x92x192cm

-

Weight:

-

590 KG

-

Certification:

-

CE

-

Marketing Type:

-

New Product 2021

-

function:

-

film cutting sealing shrink packing

-

cutter width:

-

650mm/750mm

-

speed:

-

5-8pcs/min

-

working air pressure:

-

5-7kg/cm³

-

workable packing film:

-

PE/POF/PVC

-

jet type shrink packing:

-

right

-

heating tube material:

-

stainless steel

-

Hot air circulating motor number:

-

2pcs

-

Large cooling fan:

-

yes

-

with moving wheel:

-

have

Quick Details

-

Packaging Type:

-

CANS, Bottles

-

Packaging Material:

-

Plastic, Glass

-

Driven Type:

-

Electric+pneumatic

-

Voltage:

-

220V+380V

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

K Snow

-

Dimension(L*W*H):

-

364x92x192cm

-

Weight:

-

590 KG

-

Certification:

-

CE

-

Marketing Type:

-

New Product 2021

-

function:

-

film cutting sealing shrink packing

-

cutter width:

-

650mm/750mm

-

speed:

-

5-8pcs/min

-

working air pressure:

-

5-7kg/cm³

-

workable packing film:

-

PE/POF/PVC

-

jet type shrink packing:

-

right

-

heating tube material:

-

stainless steel

-

Hot air circulating motor number:

-

2pcs

-

Large cooling fan:

-

yes

-

with moving wheel:

-

have

Products Description

Jet type tunnel plastic bottles PE film sleeve wrapping sealing heat thermal water bottles shrink wrap packing machine

Thermo shrink packing machine

is suitable for large quantity automatic shrink packaging items such as cans, glass bottles, beer, mineral water, etc. T

in can shrink packing machine

can also be used in various industries such as wood, steel, ceramics, household appliances, and computers.

One, Film wrapper machine

1.T

hermo shrink packing machine a

dopt unique cylinder design, compact structure and small floor space. It is specially suitable for multi-bottles,cans sleeve film wrapping, and can freely control the film wrapping action.

2.Manual feeding, cylinder pushing,film wrapping, sealing and cutting,moving in one design.

3.The

tin can shrink packing machine

is made by introduced foreign advanced technology and craftsmanship. The equipment performance is stable and reliable

4.The

plastic PE film sealer water bottles shrink packing machine

can choose PLC programmable controller to realize the integration of machine, electricity and pneumatic.

5. T

hermo heat shrink packing machine uses

specially designed sealing knife, the sealing is firm, does not crack, and is not easy to stick to the knife

6.Using imported photoelectric, accurate positioning. Two sets of horizontal detection photoelectricity are designed for the product;

7.The humanized design of the control box is convenient to operate.

8.The rear end of

plastic sealer shrink packing machine

is equipped with a pressing device when sealing and cutting. Even if lightly packaged items, there will be no

displacement;

|

Model

|

KS-6540

|

KS-7540

|

|

|

Voltage

|

110V/220V 50/60Hz

|

110V/220V 50/60Hz

|

|

|

Speed

|

5-8pcs/min

|

5-8pcs/min

|

|

|

Air pressure

|

5-7kg/cm³

|

5-7kg/cm³

|

|

|

Power

|

1.5Kw

|

1.5Kw

|

|

|

Package size

|

400x400x380mm

|

500x500x380mm

|

|

|

Sealing width

|

≤650mm

|

≤750mm

|

|

|

Weight

|

300kg

|

350kg

|

|

|

Size

|

925x940x1920mm

|

925x1040x1920mm

|

|

|

cooperated equipment

|

air compressor

|

|

|

Two, shrink tunnel of

plastic sealer shrink packing machine

1.Double high-power air-carrying motors ensure large circulating air volume and uniform temperature in the furnace.

2.The conveying part of

thermo shrink packing machine

adopts original high-quality frequency converter control, stepless speed regulation.

3.Stainless steel heater, faster heating and longer service life

4.Planetary reducer and high-power motor ensure smooth conveying and no shaking.

Large cooling fan, the product is quickly cooled and shaped after heat shrinking

5.Both ends of the

plastic sealer shrink packing machine

furnace are equipped with heat insulation baffles and guard plates to prevent heat loss.

6.Original high-temperature insulation curtain, greatly reducing heat loss

7.There are a variety of options, ordinary and more shaft types. The products will not move when packing small items.

The bottom of

tin can shrink packing machine

is equipped with casters to move the PE film shrink packing machine freely, equipped with bottom angle bolts, which can

be used with different heights production line.

8.The specially designed air channel system ensures the good appearance effect after packaging.

9.The

thermo shrink packing machine

internal furnace cavity plate adopts adjustable phoenix holes, which can adjust the local air volume according to the shrinkage requirements

10.The conveyor belt of

tin can shrink packing machine

can be designed as roller type, Teflon mesh or stainless steel conveyor mesh according to customer requirements.

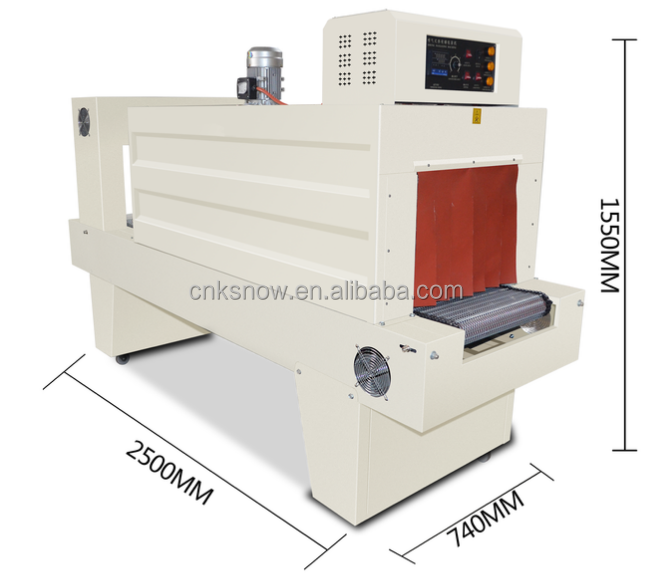

|

Model

|

BSE-5040A

|

BSE-6040A

|

BSE-7050A

|

||

|

Power

|

3phastes 220V/380V

|

3phastes 220V/380V

|

3phastes 220V/380V

|

||

|

Speed

|

1-15m/min

|

1-15m/min

|

1-15m/min

|

||

|

Channel size

|

1500x500x400mm

|

1800x600x400mm

|

1800x700x500mm

|

||

|

Max product size

|

450x400mm

|

550x450mm

|

600x450mm

|

||

|

Loading weight

|

<35kg

|

<35kg

|

<35kg

|

||

|

Size

|

2500x740x1550mm

|

2800x840x1600mm

|

2800x940x1700mm

|

||

|

Weight

|

290Kg

|

340Kg

|

450Kg

|

||

|

Suitable film

|

PE/PVC/POF/PP

|

|

|

||

Production and storage of

thermo shrink packing machine

Customer Comment

About Us

FAQ

Hot Searches