Standard Racks Plastic Rack Straight Steel Helical Nylon M4 And Pinion Gears Custom Reduction Gear

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Konlida

-

Product Name:

-

Steel Material and Rack Gear Shape Gear Rack Pinion

-

Surface treatment:

-

carbonization, case hardenning

-

Size:

-

Customized Accepted

-

Application:

-

Hotels, Building Material Shops, Manufacturing Plant,

-

Color:

-

silver / yellow

-

Process:

-

Heat Treatment+CNC Machining

-

Service:

-

ODM OEM Srvice

-

Certificate:

-

ISO9001

Quick Details

-

Weight (KG):

-

5

-

Place of Origin:

-

Jiangsu, China

-

Model Number:

-

Gear, as customer require

-

Brand Name:

-

Konlida

-

Product Name:

-

Steel Material and Rack Gear Shape Gear Rack Pinion

-

Surface treatment:

-

carbonization, case hardenning

-

Size:

-

Customized Accepted

-

Application:

-

Hotels, Building Material Shops, Manufacturing Plant,

-

Color:

-

silver / yellow

-

Process:

-

Heat Treatment+CNC Machining

-

Service:

-

ODM OEM Srvice

-

Certificate:

-

ISO9001

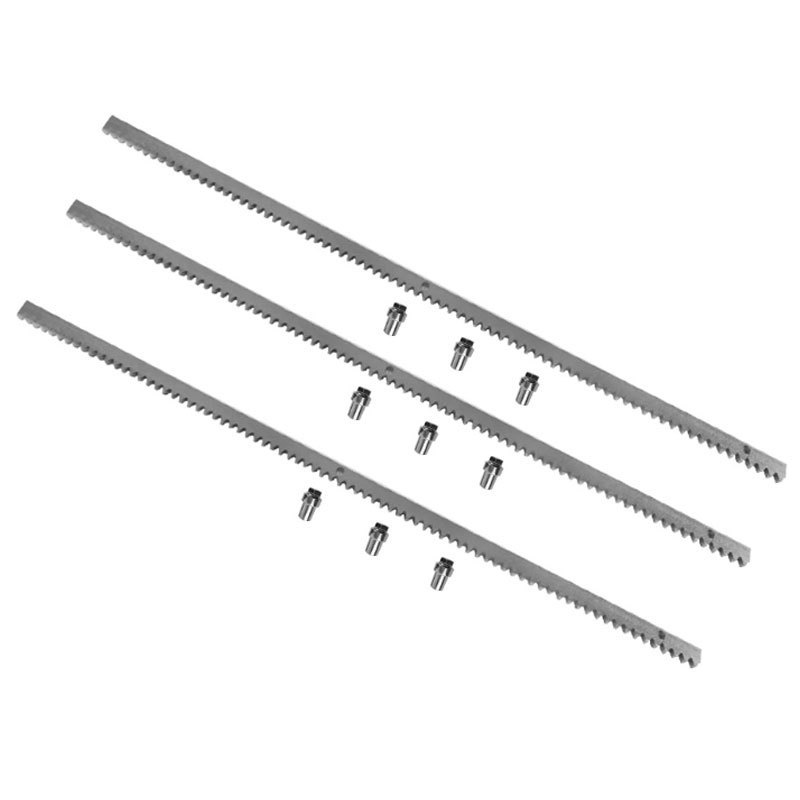

Chinese Factory Direct Rack And Pinion Gear Customized Gear Rack Gear With Good Price

OEM&ODM(

Rack Gear

)

We can make standard/special Gear andGear Rack according to drawings or samples.

Gear material can be carbon steel,

stainless steel, aluminium, copper, brass

etc.

Tell us your requirements today.

Product Description

Characteristics of

Rack and Pinion

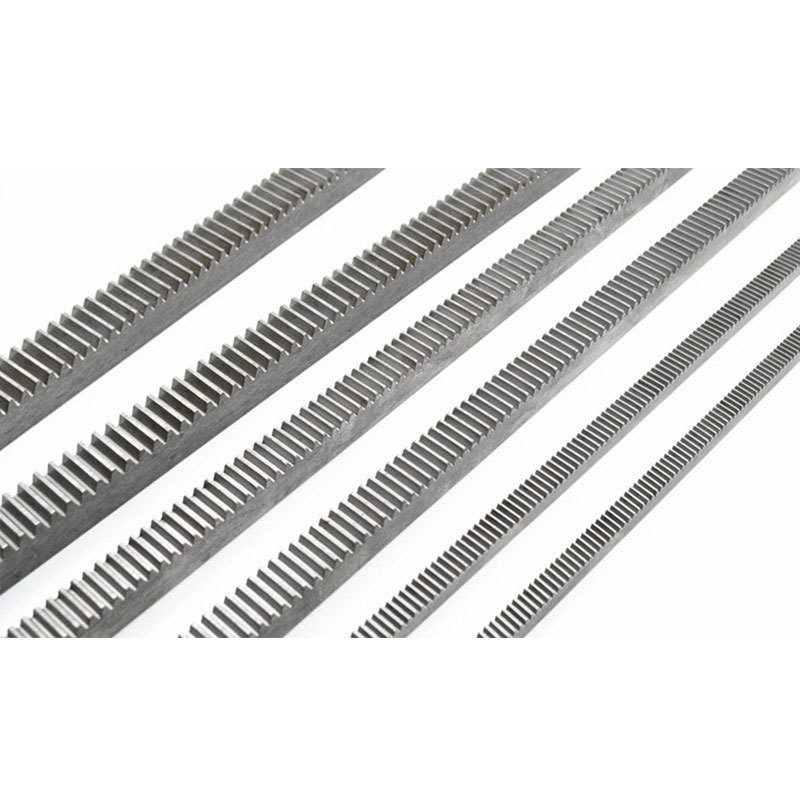

★The tooth surface of the fine-milling rack is processed by fine-milling, and the multiple finishing processes ensure that the tooth surface has small deformation and high consistency.

★The precision of the precision milling rack can reach grade 5, and the precision is high.

★The whole rack is quenched and tempered, all surfaces except the tooth surface are ironed, and the positioning accuracy is high.

★Affordable price, widely used in automation, robotics, automatic welding and other fields.

Specification

|

Product Name

|

Gear Rack Pinion for linear motion CNC machine Helical Tooth Rack and Pinion Gear Type

|

|

Type

|

Grinding Milling

|

|

Module Number

|

M1.25, M1.5, M2, M3

|

|

Color

|

Black/Silver

|

|

Surface Treatment

|

Finishing cutting/ grinding

|

|

Standard

|

DIN7/DIN6/DIN5

|

|

Toothed Portion Shape

|

Helical / spur teeth rack gear

|

|

Heat Treatment

|

Tooth surface induction hardened

|

|

Toothed Portion Shape

|

Helical / spur teeth rack gear

|

|

Length

|

Customized

|

|

OEM & ODM Availability

|

Yes

|

Advantages:

There is standard gear rack available and also special gear rack as per your drawing or samples. Our precision spur helical gear racks are welcomed by many customers for its stable high quality and competitive price.

1. Gear rack length: the longest is 4000mm without joint. It can be jointed to any length.

2. Surface: chromium plating,zinc (galvanized), black, quenching and tempering etc.

3. Quality: stable and high: accumulated tolerance 0.1mm per 1000mm for normal quality;Accumulated tolerance 0.02mm per 1000mm for 4 sides ground.Prices for above quality are very competitive for us.

4.Heat treatment: Tooth hardness can be hardened to HRC 40-55.

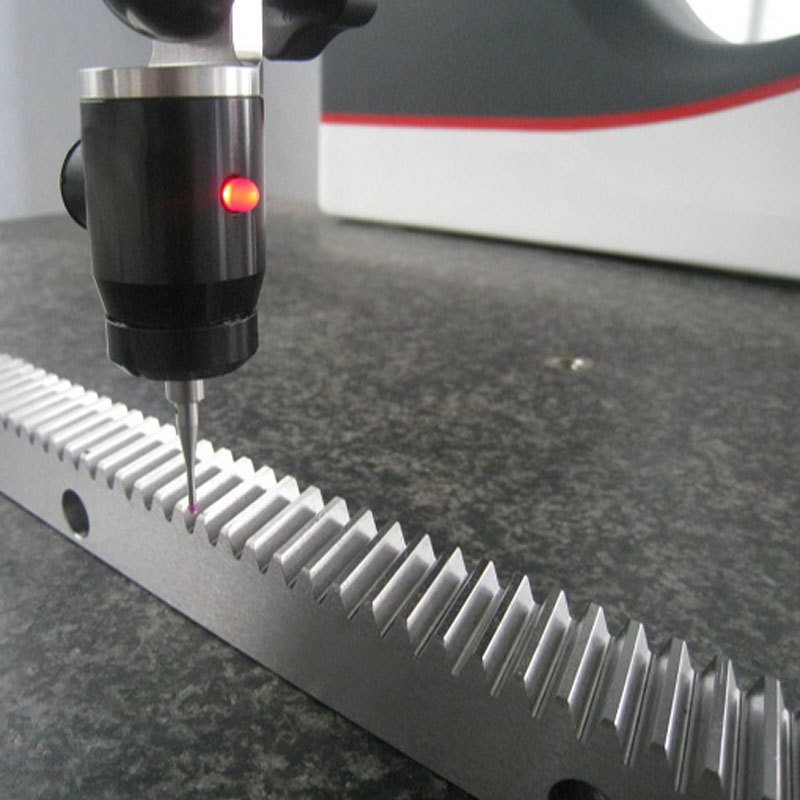

Quenching and Heat Treatment Process

In order to enhance the hardness and wear resistance of the tooth surface, the tooth surface can be subjected to high frequency quenching and heat treatment, thereby increasing the life of the gear

Application

Food Processing/Sewage treatment plant/Filling Machinery/Transport Equipment/Electronic/Medical Instruments/Glass Machinery/Aircraft Accessories/Ship Manufacturin/Appliance/Auto/Industrial equipment metal stamping hardware parts.

Product Process

Production Equipment

Inspection Method

Packing & Delivery

Hot Searches