- Product Details

- {{item.text}}

Quick Details

-

Production Speed(Cycles/min):

-

10-35 times/minute

-

Air Pressure(MPa):

-

0.7 MPa

-

Sheet Thickness(mm):

-

0.15 - 0.7 mm

-

Heating Power (kW):

-

10 kW

-

Air Comsumption(L/min):

-

0.3 L/min

-

Water Comsumption(L/min):

-

1 L/min

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

NOBLEGEYUN

-

Voltage:

-

380v 50Hz

-

Dimension(L*W*H):

-

5500*1920*1750mm

-

Weight (T):

-

2.7 T

-

Power(KW):

-

13.5

-

Sheet materia:

-

PVC PET PS

-

Max.Formed Area:

-

470*300mm

-

Max. Forming Depth:

-

47mm

-

Automatic Grade:

-

Full-auto

-

Delivery Time:

-

30 Working Days

-

Control:

-

PLC+Touch Screen

-

MOQ:

-

1 Set

-

Model:

-

JC-500D

-

Name:

-

Disposable Clear Plastic Food Container Tray Box Thermoforming Machine

Quick Details

-

Max.Forming Height(mm):

-

47 mm

-

Forming Width (mm):

-

300 mm

-

Forming Length (mm):

-

470 mm

-

Production Speed(Cycles/min):

-

10-35 times/minute

-

Air Pressure(MPa):

-

0.7 MPa

-

Sheet Thickness(mm):

-

0.15 - 0.7 mm

-

Heating Power (kW):

-

10 kW

-

Air Comsumption(L/min):

-

0.3 L/min

-

Water Comsumption(L/min):

-

1 L/min

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

NOBLEGEYUN

-

Voltage:

-

380v 50Hz

-

Dimension(L*W*H):

-

5500*1920*1750mm

-

Weight (T):

-

2.7 T

-

Power(KW):

-

13.5

-

Sheet materia:

-

PVC PET PS

-

Max.Formed Area:

-

470*300mm

-

Max. Forming Depth:

-

47mm

-

Automatic Grade:

-

Full-auto

-

Delivery Time:

-

30 Working Days

-

Control:

-

PLC+Touch Screen

-

MOQ:

-

1 Set

-

Model:

-

JC-500D

-

Name:

-

Disposable Clear Plastic Food Container Tray Box Thermoforming Machine

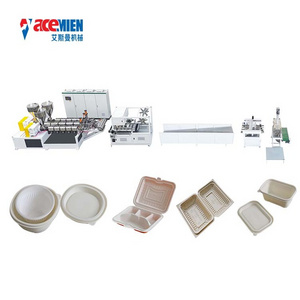

Disposable Clear Plastic Food Container Tray Box Thermoforming Machine

Machine Introduction

JC-500D Automatic Plastic Products Thermoforming Machine are developed by our research and development department, according to the demand of packing market. Absorbing the advantages of aluminum-plastic blister packaging machine and plastic molding machine, the new machine developed according to the requirements of medical “GMP” and food “QS” standards. Machine adopts automatic forming, punching and cutting as the special properties of product requires of the users. With advanced technology, safe and simple operation, avoiding the consumption of labor caused by manual punching and the pollution caused by the employees during work, guarantee the quality of products. The machine equipped with panels heating, low power consumption, small external footprint, economical and practical. So the machine is widely used in manufacturing lids, covers, trays, plates, boxes.

Main Technical Parameters

| Punch Speed | 10-35(times/minute) |

| Max.Forming Area | 470mm×300mm |

| Max.Forming Depth | 47mm |

| Stroke | 60-310mm |

| Packing Material | PVC, PET, PS(customized) |

| Material Thickness | 0.15~0.7mm |

| Max. Sheet Width | 500mm |

| Material Inner Roll Diameter | 75mm |

| Total Power | 14.1kW(380V) |

| Compressed Air(Mpa) | 0.6-0.8Mpa |

| Mold Cooling | 60L/H tap water/recycle water |

| Overall Dimension | 5500×1920×1750mm |

| Weight | 2700kg |

Various Products Made By The Machine

This machine applicable to the plastic sheet such as PVC, PET, PS(customized) , to making cup lid, cover, tray, container, box, plate. Just need to replace the mold can be achieved!

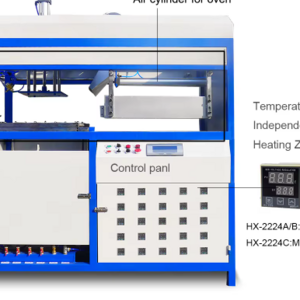

Machine Features

1) The automatic control is realized by the combination of programmable controller (PLC), man-machine interface, photoelectric system and three-servo system, digitization operation is simple and intuitive.

2) Automatic lifting and loading material system is safe and labor-saving , plate type upper and lower preheating device temperature control system is stable to ensure uniform heating, various molding methods to ensure the appearance of the product is beautiful, punching and punching knife are durable and no burr, strong pressure cutting laser knife has low cost and good effect, mold replacement is simple, main engine adopts the frequency conversion speed regulation to run smoothly.

3) The whole body is welded by steel box, the structure is firm and no deformation, the bracket and the box are under pressure molding, high density and no air holes, and the appearance is evenly wrapped with stainless steel, which is beautiful and easy to maintain.

4) The roller servo traction system makes the machine run more stable and reliable, increases the traction length and can directly set the traction length and traction speed in the man-machine interface through PLC programming, which increases the forming area and expands the applicable range of the machine.

5) Adopt planar linkage mechanism is to make larger transmission force , smaller inertia effect, stable operation, and larger pressure cutting force. Equipped with intelligent servo control system, laser knife is small in size, low in cost, convenient in adjustment and replacement, after the finished product is cut, the product is smooth and no burr.

6) This machine is also equipped with a powerful automatic servo stacking system, which can save labor costs for users.

7) Can be equipped with the function of cursor-to-version.

Related Machine

Automatic PP Lids&Boxes Making Thermoforming Machine

Automatic Paper Cup Lid Cover Forming Making Machine

Certification

Customers From All Over The World

Machine quality wins the trust of customers

We attend exhibitions every year