- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Stamped Mould

-

Product Name:

-

Concrete Stamp Molds

-

Keyword:

-

Concrete Mold

-

Material:

-

Rubber

-

Thickness:

-

20-25mm

-

Advantage:

-

Flexibility

-

Color:

-

Muti-Color

-

Package:

-

Woven Bags

-

Weight:

-

Depend Designs

-

Size:

-

Customer Size Accepted

-

Usage:

-

Driveway, pool deck, patio, walkway or walls

Quick Details

-

Shaping Mode:

-

Compression Mould

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Sense

-

Model Number:

-

Stamped Mould

-

Product Name:

-

Concrete Stamp Molds

-

Keyword:

-

Concrete Mold

-

Material:

-

Rubber

-

Thickness:

-

20-25mm

-

Advantage:

-

Flexibility

-

Color:

-

Muti-Color

-

Package:

-

Woven Bags

-

Weight:

-

Depend Designs

-

Size:

-

Customer Size Accepted

-

Usage:

-

Driveway, pool deck, patio, walkway or walls

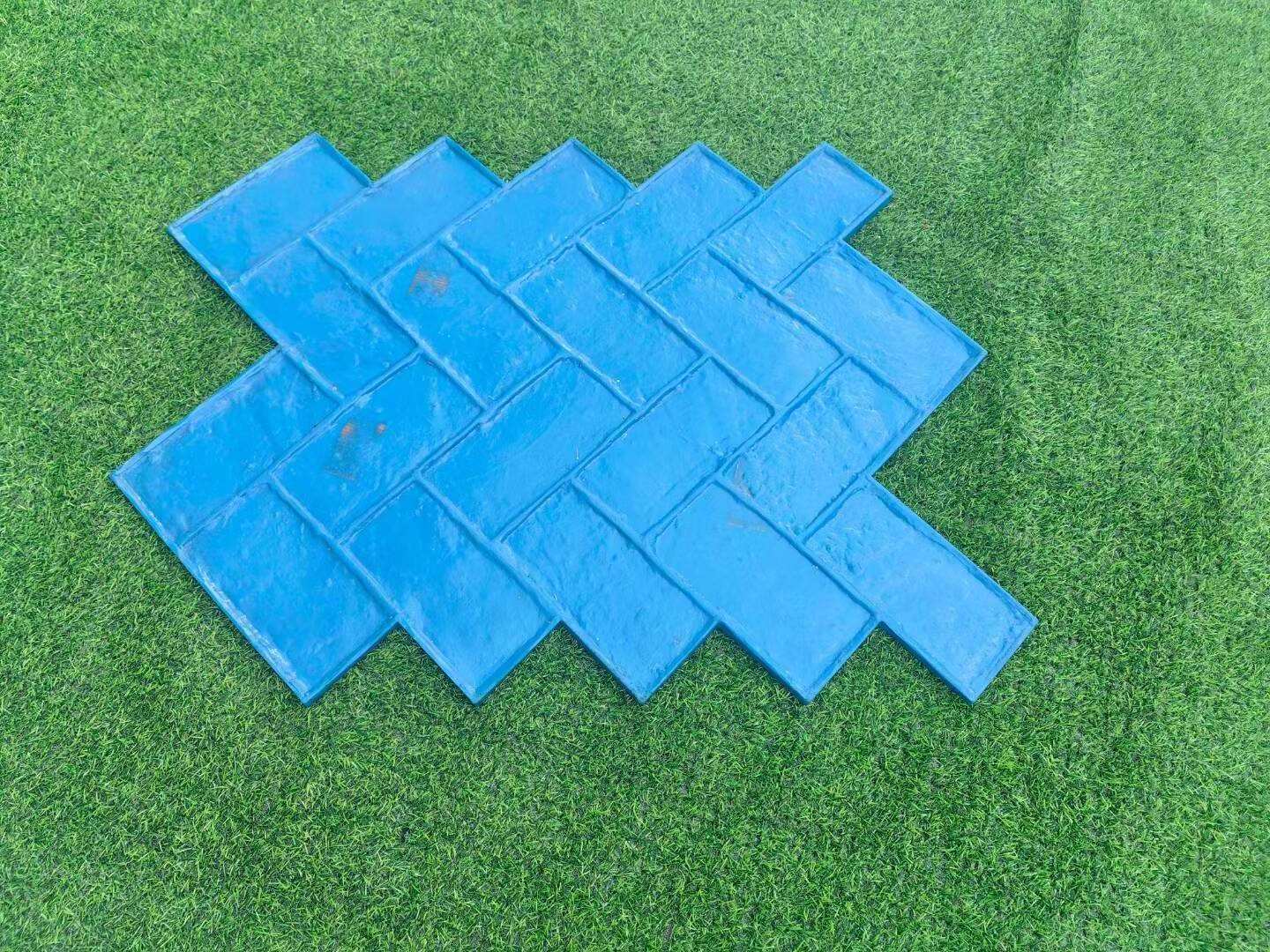

Products Description

|

Name

|

Concrete Stamped Molds

|

|

Mold life

|

3-5 Years

|

|

Material

|

Rubber

|

|

Color

|

Blue/Red

|

|

Application

|

1. Municipal engineering: streets, sidewalks, road isolation belts, theme parks, cultural squares, landscape engineering;

2. Commercial: commercial buildings, hotels, restaurants, bars, large shopping malls, exhibition centers, supermarkets, shops, parking lots;

3. Residential: apartments, villas, residential quarters, courtyards, gardens;

4. Entertainment venues: parks, playgrounds, water feature pools, swimming pools;

5. Others: industrial plants, schools, kindergartens, bus system platforms, interior and exterior decorations of buildings. |

|

Advantage

|

1. Patterns and colors can be grouped arbitrarily and the overall molding can be complete at one time;

2. Compressive strength is generally more than three times that of ordinary concrete with good abrasion resistance;

3. Using inorganic pigments, the color is firm and durable, with good UV resistance, suitable for the complicated and changeable tempreature, humidity;

4. It is oil-proof, water-proof, non-slip and the surface will not crack, fall off or fade.

|

Match products for concrete stamping construction:

1--Colorful hardener, 30kg/bag, use 3kg for one square meter

2--Release agent, 10kg/bag, use 0.15kg for one square meter

3--Protective agent, 25kg/barrel, 0.2kg for one square meter

Manufacturing Process

Step--1:

Paving concrete

Step--2:

Spray colorful hardener

Step--3:

Use bull float to make lavel

Step--4:

Spray colorful hardener secondly

Step--5:

Use bull float to make lavel secondly

Step--6:

Spray release agent

Step--7:

Stamped molds

Step--8:

Rinse release agent

Step--9:

Brush protective agent

Related Products

Packaging & Transportation

FAQ

Q1: How about your molds quality ?

A1: You can be rest assured, the quality of our molds is good, we have been engaged in the mold industry for more than 10 years.

Q2: Could i customize for my own designs?

A1: Of course, we can customize according to your drawings.

Q3: What's the materials of the molds?

A3: There are ABS, plastic, fiberglass, silicone rubber materials.

Q4: Can you help me how to use the molds?

A4: Yes, we support

videos, technical support and easy operation.

Hot Searches