- Product Details

- {{item.text}}

Quick Details

-

Power:

-

1500

-

Dimension(L*W*H):

-

520*250*555mm

-

Weight:

-

50 KG

-

Output product name:

-

butter

-

Type:

-

peanut butter machine

-

Application:

-

Process Sauce

-

Speed:

-

2930r/min

-

Production Capacity:

-

10-15kg/h

-

Advantage:

-

High Effieciency

-

MOQ:

-

1set

-

Usage:

-

Nut Paste Grinding

-

Function:

-

Grinding Sesame

-

Feature:

-

High Efficiency Easy Operation

-

Material:

-

SUS 304

Quick Details

-

Marketing Type:

-

Hot Product

-

Place of Origin:

-

China

-

Voltage:

-

220/380v

-

Power:

-

1500

-

Dimension(L*W*H):

-

520*250*555mm

-

Weight:

-

50 KG

-

Output product name:

-

butter

-

Type:

-

peanut butter machine

-

Application:

-

Process Sauce

-

Speed:

-

2930r/min

-

Production Capacity:

-

10-15kg/h

-

Advantage:

-

High Effieciency

-

MOQ:

-

1set

-

Usage:

-

Nut Paste Grinding

-

Function:

-

Grinding Sesame

-

Feature:

-

High Efficiency Easy Operation

-

Material:

-

SUS 304

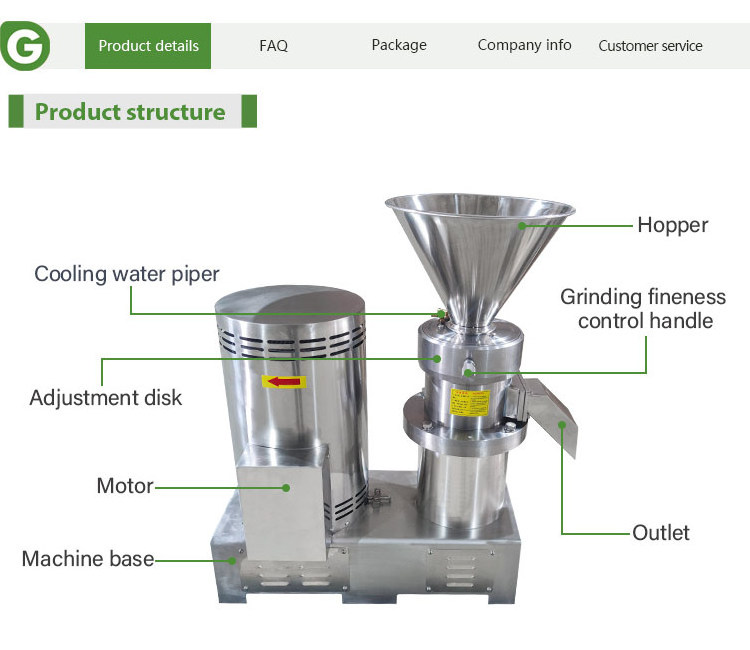

Introduction

Through the relative motion of stators and rotors of different geometric shapes under high-speed rotation, the processed materials are subjected to strong shearing force, frictional force and impact force when passing through their annular variable gap under the action of self-weight, air pressure and centrifugal force. , high-frequency vibration and other compound forces, the material is effectively dispersed, broken, emulsified, mixed, so as to obtain the ideal product.

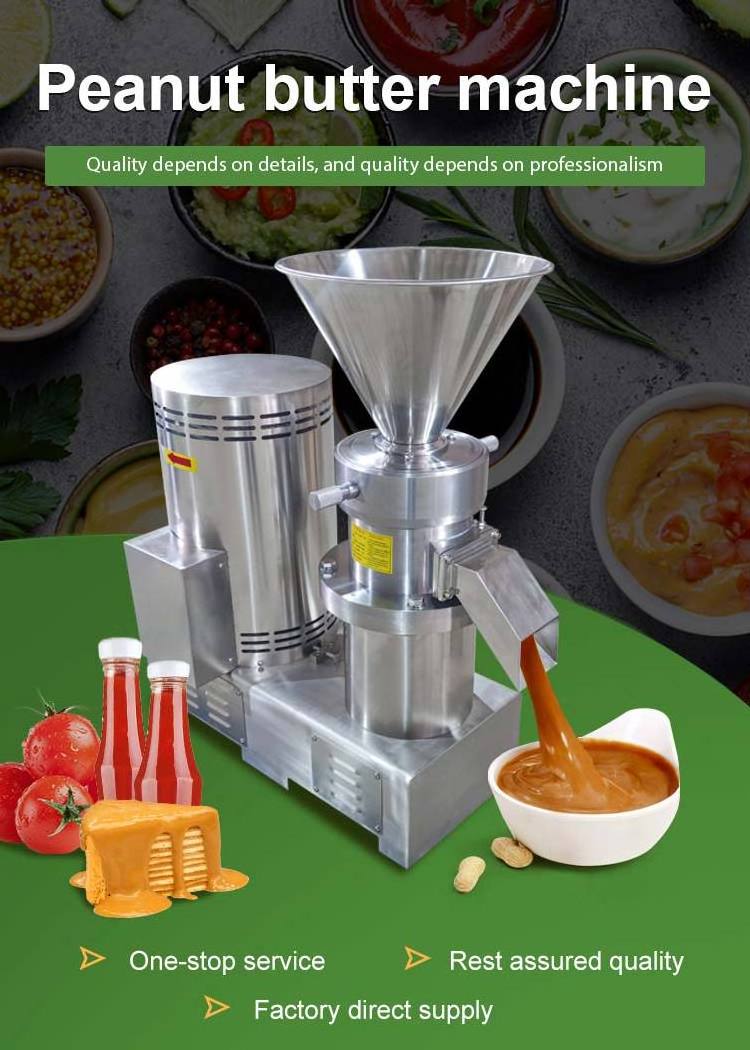

Application

The main technical indicators have reached the excellent level of domestic similar products. This machine has excellent superfine grinding, dispersing, emulsifying, mixing and other performance. After the material is processed by this mill, the particle size can reach 2-60 microns, and the homogeneity can reach more than 95%. It is an ideal equipment for ultrafine processing. It integrates various properties of machines such as homogenizer, ball mill, three-roller, mixer, etc., and its efficiency is several times that of the above machines.

Features

1. This machine keeps the traditional colloid mill with reasonable structure, simple operation, small size, light weight, wide adaptability, simple speed change, and can change different types of motors for different objects.

2. The main working parts of this machine are stator and rotor. The gap between the stator and rotor can be adjusted slightly through the positioning plate, and it is equipped with a dial, which is easy to control and ensures the processing quality of the product.

3. According to different purposes, the stator and rotor of different materials can be selected, which is convenient for disassembly and assembly.

4. The speed of the machine can be adjusted, and the user can order the appropriate speed from our unit according to the material processing situation.

Parameter

| Model | GD-J50 | GD-J80 | GD-J110 | GD-J130 | GD-J160 | GD-J180 | GD-J210 | GD-J240 | GD-J300 |

| Capacity(t/h) | 0.005-0.03 | 0.1-0.5 | 0.3-1.2 | 0.4-2 | 0.6-4 | 0.8-6 | 1.5-8 | 4.0-12 | 6.0-25 |

|

Motor Speed(m/min) |

2820 | 2890 | 2900 | 2930 | 2930 | 2930 | 2950 | 2970 | 2970 |

| Rotor Dia (mm) | 50 | 80 | 110 | 130 | 160 | 180 | 210 | 240 | 300 |

Q1 How long is it fried? What is the temperature for frying?

Generally fried for 40-60s, the oil temperature is controlled at 160-180 ℃.

Q2 How long does it take for dewater and deoiling?

About 2 minutes.

Q3 What material is the machine?

The whole machine is made of 304 stainless steel.

Q4 How many finished products can be produced from 1kg of potatoes?

Can produce 0.6-0.7kg French fries, 0.3kg potato chips.

Q5 Can the temperature of the blanching and frying machine be adjusted?

Temperature adjustable.

Install waterproof membrane to reduce dust and water pollution

Standard wooden boxes are used as outer packaging to reduce bumps in international transportation

Delivery Time

For stock type, we can send within 48hrs after confirming order.

For customized type , delivery date need to be negotiated before taking order.