- Product Details

- {{item.text}}

Quick Details

-

Water Capacity:

-

40L Oxygen Cylinder

-

Working Pressure:

-

150bar

-

Testing Pressure:

-

250bar

-

Outside Diameter:

-

219mm

-

Certification:

-

ISO9809/GB5099 Oxygen Cylinder

-

Wall Thickness:

-

5.7mm

-

Height:

-

About 1320mm without valve and cap

-

Weight:

-

About 47.5kg wihtout valve and cap

-

Color:

-

Customer's Requirement

-

Valve:

-

QF-2

Quick Details

-

Material:

-

Steel

-

Use:

-

Oxygen

-

Place of Origin:

-

Shandong, China

-

Water Capacity:

-

40L Oxygen Cylinder

-

Working Pressure:

-

150bar

-

Testing Pressure:

-

250bar

-

Outside Diameter:

-

219mm

-

Certification:

-

ISO9809/GB5099 Oxygen Cylinder

-

Wall Thickness:

-

5.7mm

-

Height:

-

About 1320mm without valve and cap

-

Weight:

-

About 47.5kg wihtout valve and cap

-

Color:

-

Customer's Requirement

-

Valve:

-

QF-2

JP Marking Seamless Steel Oxygen Cylinder

1.Manufacturer can supply both industrial gas and gas cylinders.

2.Proucts exported to 100countries.

3. Volume: 1.4Liter-80Liter Oxygen Cylinder.

Our Seamless Steel Gas Cylinders are mainly produced conformity with Standard GB5099, ISO9809 and EN1964. The raw material is either Seamless Steel Pipe or Steel Billet.

Seamless Steel Gas Cylinders can be widely used in many fields, such as industry, medical equipment, fire protection and scientific research, for storage and transport of permanent gases and high pressure liquefied gases, such as Oxygen Gas, Carbon Dioxide Gas, Argon Gas and many other pertinent Gases.

1. GB5099 Oxygen Cylinder

| Type |

Diameter(mm) |

Capacity(L) |

Height(mm) |

Weight (kg) |

Working pressure(Mpa) |

Material |

|

WMA108-1.4-15 |

108 |

1.4 |

238 |

2.96 |

15 |

37Mn |

|

WMA108-2-15 |

108 |

2.0 |

320 |

3.75 |

15 |

|

|

WMT108-2-15 |

108 |

2.0 |

317 |

3.72 |

15 |

|

|

WMA121-3.2-15 |

121 |

3.2 |

390 |

5.02 |

15 |

|

|

WMT121-3.2-15 |

121 |

3.2 |

385.8 |

4.98 |

15 |

|

|

WMA121-4-15 |

121 |

4.0 |

485 |

6.16 |

15 |

|

|

WMT121-4-15 |

121 |

4.0 |

470 |

5.95 |

15 |

|

|

WMA140-4-15 |

140 |

4.0 |

372 |

5.77 |

15 |

|

|

WMA140-5-15 |

140 |

5.0 |

458 |

7.52 |

15 |

|

|

WMA140-6.3-15 |

140 |

6.3 |

524 |

8.72 |

15 |

|

|

WMA140-7-15 |

140 |

7.0 |

593 |

9.84 |

15 |

|

|

WMA140-8-15 |

140 |

8.0 |

671 |

10.72 |

15 |

|

|

WMA140-10-15 |

140 |

10 |

845 |

13.4 |

15 |

|

|

WMA152-7-15 |

152 |

7.0 |

528 |

9.57 |

15 |

|

|

WMA152-8-15 |

152 |

8.0 |

600 |

10.66 |

15 |

|

|

WMA152-10-15 |

152 |

10.0 |

726 |

12.6 |

15 |

|

|

WMA159-10-15 |

159 |

10.0 |

685 |

14.15 |

15 |

|

|

WMA159-12-15 |

159 |

12.0 |

800 |

16.34 |

15 |

|

|

WMA159-15-15 |

159 |

15.0 |

975 |

19.66 |

15 |

|

|

WMA219-20-15 |

219 |

20.0 |

730 |

29.00 |

15 |

|

|

WMA219-25-15 |

219 |

25 |

885 |

33.00 |

15 |

|

|

WMA219-32-15 |

219 |

32 |

1080 |

40.00 |

15 |

|

|

WZA232-47-15 |

232 |

47.0 |

1360 |

51.00 |

15 |

|

|

WMA219-50-15 |

219 |

50.0 |

1600 |

57.00 |

15 |

|

|

WMA232-50-15 |

232 |

50.0 |

1380 |

65.00 |

15 |

|

|

WGA232-40-20 |

232 |

40.0 |

1170 |

52.00 |

20 |

34CrMo4 |

|

WGA232-47-20 |

232 |

47.0 |

1360 |

55.00 |

20 |

|

|

WGA232-50-20 |

232 |

50.0 |

1440 |

56.00 |

20 |

2. ISO 9809 Oxygen Cylinder

|

Type |

Material |

Working Pressure(Mpa) |

Test pressure(Mpa) |

Capacity(L)

|

OD (mm) |

Length (mm) |

Weight ( kg) |

Standard |

|

WZA232-50-15 |

37Mn |

15 |

22.5 |

50 |

232 |

1435 |

54 |

GB5099-94 |

|

IWGA232-36-20 |

34CrMo4 |

20 |

30 |

36 |

232 |

1065 |

43 |

ISO9809-1 |

|

IWGA232-40-20 |

34CrMo4 |

20 |

30 |

40 |

232 |

1170 |

47 |

ISO9809-1 |

|

IWGA232-46.7-20 |

34CrMo4 |

20 |

30 |

46.7 |

232 |

1350 |

53 |

ISO9809-1 |

|

IWGA232-47-20 |

34CrMo4 |

20 |

30 |

47 |

232 |

1360 |

53 |

ISO9809-1 |

|

IWGA232-50-20 |

34CrMo4 |

20 |

30 |

50 |

232 |

1440 |

56 |

ISO9809-1 |

|

IWMA219-40-15 |

37Mn |

15 |

22.5 |

40 |

219 |

1315 |

48.5 |

ISO9809-3 |

|

IWMA232-40-15 |

37Mn |

15 |

22.5 |

40 |

232 |

1170 |

45.3 |

ISO9809-3 |

|

IWMA232-46.7-15 |

37Mn |

15 |

22.5 |

46.7 |

232 |

1345 |

51.2 |

ISO9809-3 |

|

IWMA232-47-15 |

37Mn |

15 |

22.5 |

47 |

232 |

1355 |

51.6 |

ISO9809-3 |

|

IWMA232-50-15 |

37Mn |

15 |

22.5 |

50 |

232 |

1435 |

54.3 |

ISO9809-3 |

3. EN 1964-1 Oxygen Cylinder

|

Type |

DO(mm) |

Capacity(L) |

Length (mm) |

Weight (KG) |

WP (bar) |

Wall thickness (mm) |

Material |

|

EN1964 204-40-200 |

204 |

40 |

1510 |

48 |

200 |

4.6 |

34CrMo4 |

|

EN1964 229-40-166.7 |

229 |

40 |

1250 |

50 |

166.7 |

4.8 |

34CrMo4 |

|

EN1964 229-50-166.7 |

229 |

50 |

1510 |

58 |

166.7 |

4.8 |

34CrMo4 |

|

EN1964229-40-200 |

229 |

40 |

1250 |

53 |

200 |

5.2 |

34CrMo4 |

|

EN 1964 229-45-200 |

229 |

45 |

1370 |

57 |

200 |

5.2 |

34CrMo4 |

|

EN1964 229-50-200 |

229 |

50 |

1510 |

59 |

200 |

5.2 |

34CrMo4 |

Packing: Nude Packing with upper and lower protection net or nylon bag for Gas Cylinder .

Delivery time: Within 30 days after the receipt of deposit.

Payment term: 30% T/T deposit, 70% T/T against B/L copy. Or 100% Irrevocable L/C at sight.

Gas Cylinder Production Flow

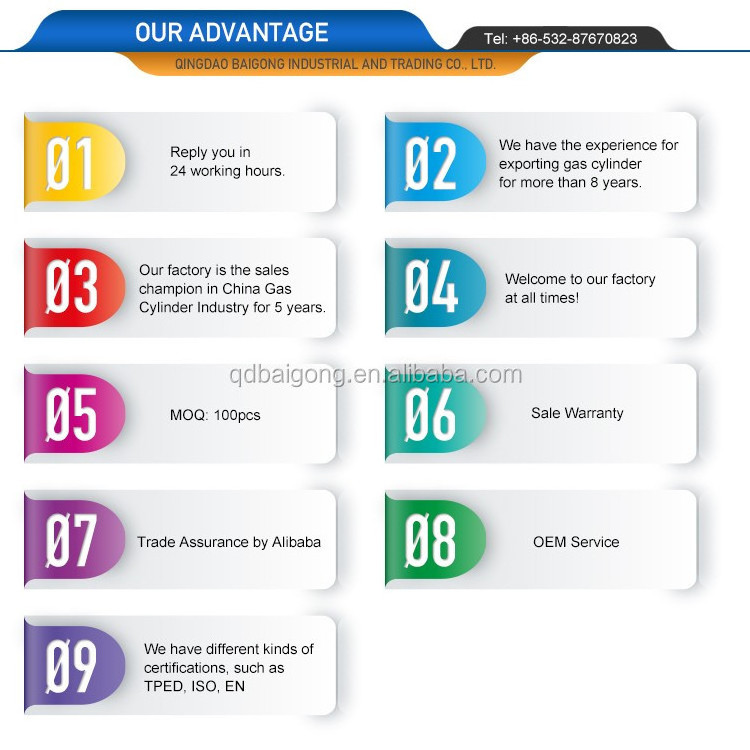

1. Reply your enquiry in 24 working hour.

2. Gas Cylinder Color could be painted according to customer's requirements.

3. Valve of Gas Cylinder could be changed according to customer's requirements.

4. Customer name could be engraved or painted on Gas Cylinder.

1. What is the capacity of the gas cylinder you can provide?

From 2.5Liter to 52Liter

2. What's your gas cylinder manufacture standard?

GB5099, ISO9809-1, ISO9809-3

3. What's your MOQ?

Usually our MOQ is 100pcs cylinders.

4. What's your packing method?

Each cylinder with upper and lower protection plastic nets, or packed by half pp bag

5. What's your delivery time for gas cylinder?

Usually within 25 days after the receipt of confirmed order.

6. What's your payment term?

40% T/T deposit, 60% T/T against B/L copy or 100% Irrevocable L/C at sight

7. Is there any cautions to use gas cylinders?

1) The use and testing of gas cylinder shall be subject to “Safety inspection regulations for gas cylinders” issued by State Bureau of Quality and Technical Supervision. 2) The gas cylinder shall away from heat and sunlight exposure. The distance from fire should be no less than 10 meter. And it is prohibited to hit the cylinders. 3) It is prohibited to use fire to heat the valve if it was frozen. 4) The nozzle of the gas cylinder was strictly prohibited from oil contamination 5) The gas in the cylinder cannot be entirely exhausted, it would be better to remain not less than 0.040 MPa residual pressure 6) The filling pressure of gas cylinder cannot exceed the prescribed pressure.