- Product Details

- {{item.text}}

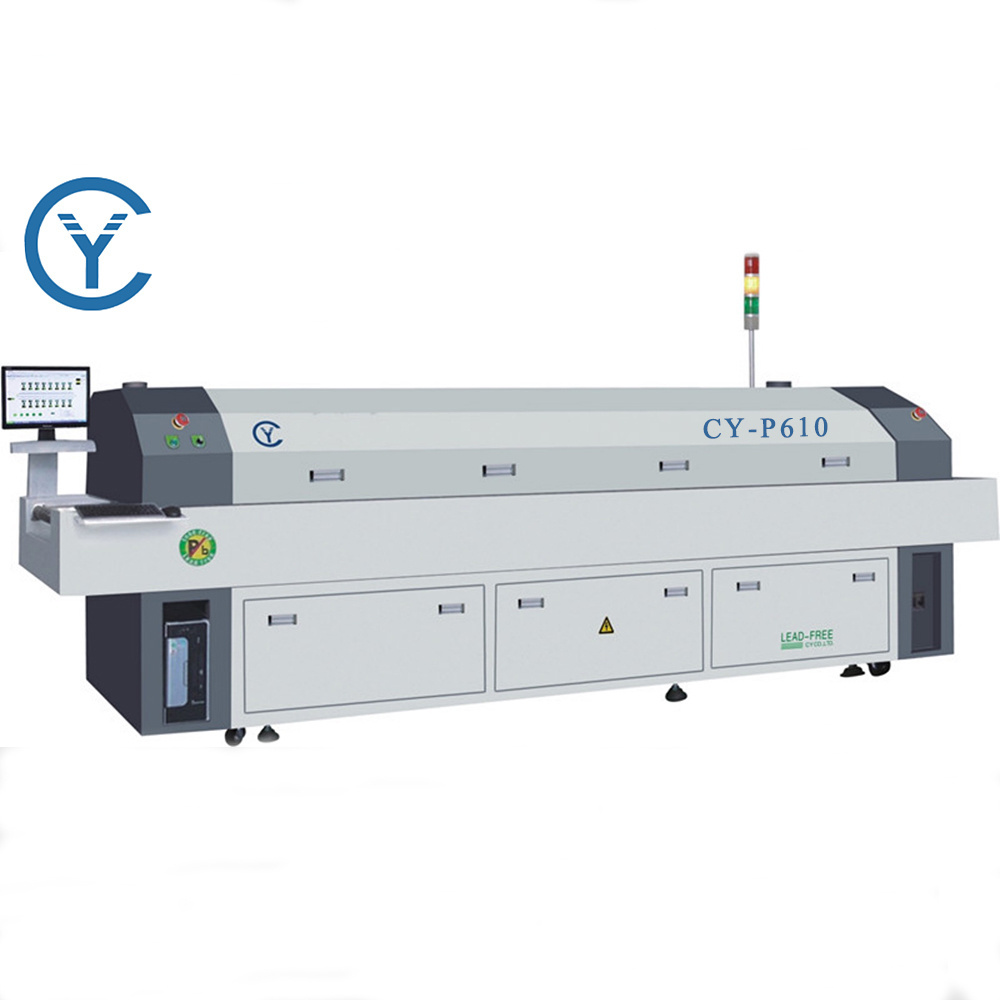

Quick Details

-

Brand Name:

-

CY

-

Use:

-

Soldering

-

Voltage:

-

110-240V

-

Dimensions:

-

L5050mm*W1200mm*H1450mm

-

Current:

-

60A

-

Weight (KG):

-

1600 KG

-

Number of Heating Zones:

-

Up 8/Bottom 8

-

Exhaust Volume:

-

10M3/minx2 Exhausts

-

Control System:

-

PLC+Computer

-

Temperature Control Method:

-

PID + SSR

-

Transmission Agent:

-

Chain + Mesh

-

Electric Supply Required:

-

3 phase,380V 50/60Hz

-

Power For Warm Up:

-

48 KW

-

Power Consumption:

-

Approx.7.5Kw

-

Warming Time:

-

20Min

-

Temp. Setting Range:

-

Room Temp.-- 350°C

Quick Details

-

Applicable Industries:

-

SMT, LED, PCB, Industry

-

Marketing Type:

-

New Product 2024

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

CY

-

Use:

-

Soldering

-

Voltage:

-

110-240V

-

Dimensions:

-

L5050mm*W1200mm*H1450mm

-

Current:

-

60A

-

Weight (KG):

-

1600 KG

-

Number of Heating Zones:

-

Up 8/Bottom 8

-

Exhaust Volume:

-

10M3/minx2 Exhausts

-

Control System:

-

PLC+Computer

-

Temperature Control Method:

-

PID + SSR

-

Transmission Agent:

-

Chain + Mesh

-

Electric Supply Required:

-

3 phase,380V 50/60Hz

-

Power For Warm Up:

-

48 KW

-

Power Consumption:

-

Approx.7.5Kw

-

Warming Time:

-

20Min

-

Temp. Setting Range:

-

Room Temp.-- 350°C

Products Description

Hot selling CY series lead-free SMT reflow soldering machine

|

F series double rail Reflow soldering technology parameters

|

|

|

|

|||

|

Series

|

F series double rail

|

|

|

|||

|

Model

|

CY-F820

|

CY-F1020

|

CY-F1220

|

|||

|

Heating zones

|

UP 8 / down 8

|

Up 10 / down 10

|

Up 12 / down 12

|

|||

|

Cooling zones

|

Up 2 /down 2 or UP 3 / down 3(optional)

|

|

|

|||

|

Heating zone length

|

2900mm

|

3600mm

|

4400mm

|

|||

|

PCB maximum width

|

Rail type:400mm Belt type: 550mm

|

|

|

|||

|

Rail wide adjust range

|

50-400mm

|

|

|

|||

|

Transport direction

|

L→R(R→L)

|

|

|

|||

|

Fixing method of transport guide rail

|

Front ( optional : back end ) |

|

|

|||

|

Conveyor height

|

Belt:900±20mm,Chain:900±20mm

|

|

|

|||

|

Transmission way

|

Chain+ belt

|

|

|

|||

|

Conveyor speed

|

300-2000mm/Min

|

|

|

|||

|

The power supply

|

3-phase 380V 50 / 60Hz

|

|

|

|||

|

Starting power

|

35Kw

|

48Kw

|

68Kw

|

|||

|

Normal work consumed power

|

Approx.7.5Kw

|

Approx.8.5Kw

|

Approx.10Kw

|

|||

|

Heating up time

|

About 15-20minutes

|

|

|

|||

|

The temperature control range

|

Room Temperature-350℃

|

|

|

|||

|

Temperature control mode

|

Full computer PID closed loop control, SSR drive

|

|

|

|||

|

The whole machine control mode

|

Computer +PLC

|

|

|

|||

|

The temperature control precision

|

±1℃

|

|

|

|||

|

The deviation of PCB temperature distribution

|

±1-2℃

|

|

|

|||

|

Cooling way

|

Air machine: air cooling, nitrogen machine: water cooling

|

|

|

|||

|

Abnormal alarm

|

Abnormal temperature (ultra high or ultra low after constant temperature)

|

|

|

|||

|

Three color light

|

Yellow - temperature rise; Green - constant temperature; Red anomaly

|

|

|

|||

|

Weight

|

Approx.1700Kg

|

Approx.1900Kg

|

Approx.1900Kg

|

|||

|

Dimensions(mm)

|

5050×1400×1450

|

5750×1400×H450

|

6480×1400×H450

|

|||

|

Exhaust air requirements

|

10 cubic / min 2 channel ∮ 200mm

|

|

|

|||

Exhibition

Certifications

FAQ

Q: What's your main service? A: We provide total SMT machines and soluton service, professional technology support and after

sales. Q: Are you a trade company or a manufacture? A: We are an experienced manufacturer of SMT and PCBA equipment, OEM & ODM

service are available. Q: What is your delivery date? A: The delivery date is about 35 days after receipt of payment. Q: What is

your payment terms? A: 30% deposit in advance and 70% balance before shipment. Q: Can you provide a whole line solution? A: Yes,

We can supply SMT line, Coating line, DIP line and LED production line.

sales. Q: Are you a trade company or a manufacture? A: We are an experienced manufacturer of SMT and PCBA equipment, OEM & ODM

service are available. Q: What is your delivery date? A: The delivery date is about 35 days after receipt of payment. Q: What is

your payment terms? A: 30% deposit in advance and 70% balance before shipment. Q: Can you provide a whole line solution? A: Yes,

We can supply SMT line, Coating line, DIP line and LED production line.

Product packaging

Recommend Products

Hot Searches