- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.4-0.8 mm

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

YUFA

-

Voltage:

-

220V 60Hz 3phases

-

Dimension(L*W*H):

-

5.6 m*1.1m*1.3m

-

Weight:

-

2800 kg

-

Feeding width:

-

as the tile profile

-

Marketing Type:

-

Chile popular used

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr 12 Mov

-

Shaft material:

-

45# Steel Outer Diameter: 50mm

-

Raw material:

-

PPGI PPGL GI GL

-

Control system:

-

PLC(detla) System

-

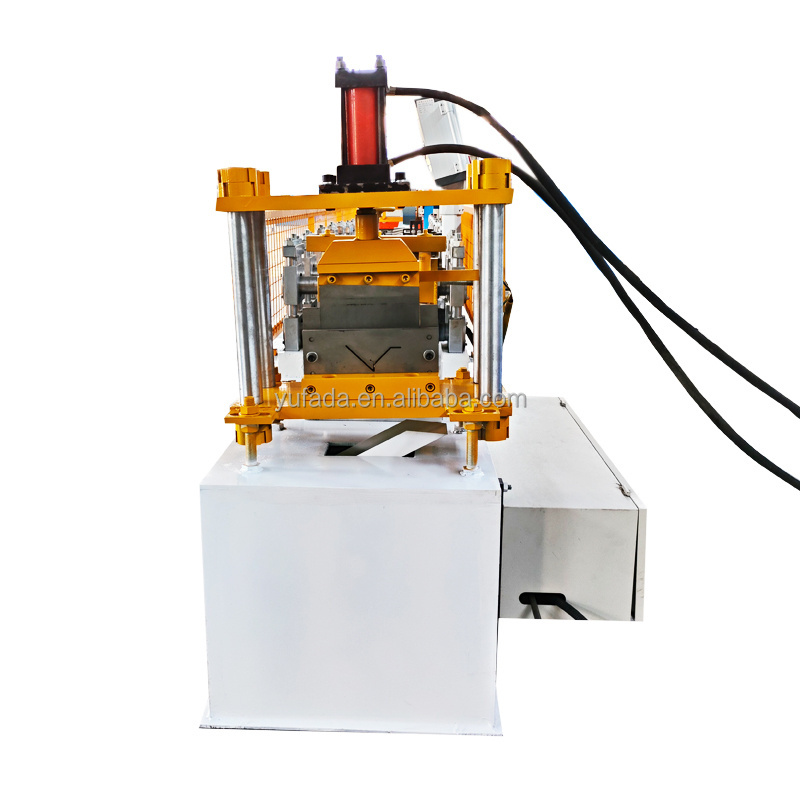

Main frame:

-

Square Tube Welding

-

Thickness:

-

0.85mm

-

Profiles:

-

Furring Channel Machine

-

Motor brand:

-

China Famous Brand

-

Cutting type:

-

Automatic Hydraulic Cutting

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

20-30mm/min

-

Rolling thinckness:

-

0.4-0.8 mm

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

YUFA

-

Voltage:

-

220V 60Hz 3phases

-

Dimension(L*W*H):

-

5.6 m*1.1m*1.3m

-

Weight:

-

2800 kg

-

Feeding width:

-

as the tile profile

-

Marketing Type:

-

Chile popular used

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr 12 Mov

-

Shaft material:

-

45# Steel Outer Diameter: 50mm

-

Raw material:

-

PPGI PPGL GI GL

-

Control system:

-

PLC(detla) System

-

Main frame:

-

Square Tube Welding

-

Thickness:

-

0.85mm

-

Profiles:

-

Furring Channel Machine

-

Motor brand:

-

China Famous Brand

-

Cutting type:

-

Automatic Hydraulic Cutting

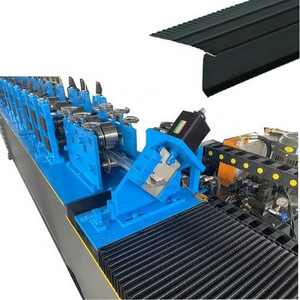

Amercia Mexico popular Custom Drip Edge Machine

A metal drip profile roll forming machine is a piece of industrial equipment used in the manufacturing of metal drip profiles.

Drip profiles, also known as drip edges or gutter profiles, are metal strips or channels typically used in roofing and construction to direct water away from critical areas and prevent water damage.

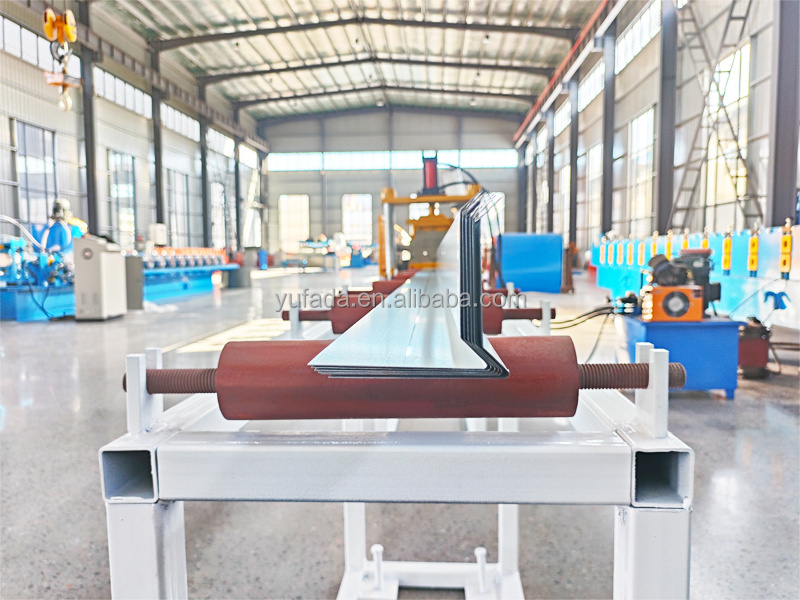

The roll forming process involves feeding a metal coil through a series of rollers and dies that progressively shape the metal into the desired profile.

In the case of a metal drip profile roll forming machine, it is designed specifically to produce drip profiles with a consistent shape and dimensions.

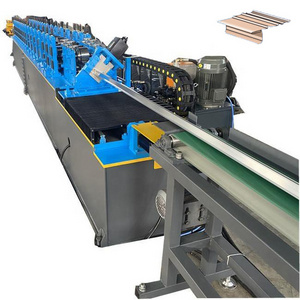

America Popular Used Galvanized Steel Roof Trim Edge Making Machine Drip Edge Roll Forming Machine

Decoiler-roll forming machine-PLC control box-hydraulic cutter-Run out table

| Article No. | Item Name | Specification |

| 1 | Width of feeding material | As the tile profile |

| 2 | Thickness of feeding material | 0.3-0.6 mm coil sheet |

| 3 | Roller station | 11 stations |

| 4 | Shaft Diameter | 60 mm |

| 5 | Productivity | 20-55 m/min |

| 6 | Rollers' material | 45# steel with 0.05mm chrome |

| 7 | Shaft material | 45# steel with 0.05mm chrome |

| 8 | Weight | 2.8 tons |

| 9 | Size | 5.6*1.1*1.3m |

| 10 | Voltage | 220V 60Hz 3phases |

| 11 | Control | PLC |

| 12 | Decoiler | 3 tons |

| 13 | Motor | 5.5 kw |

| 14 | Driving way | Chain transmission |

| 15 | Chain size | 1.2 inch |

| 16 | Cutting system | Hydraulic cutter |

Details pictures of America Popular Used Galvanized Steel Roof Trim Edge Making Machine Drip Edge Roll Forming Machine

These machines are highly automated and can produce drip profiles at a high rate, ensuring uniformity and precision in the final products.

Metal drip profiles are crucial for protecting buildings from water damage by guiding rainwater away from vulnerable areas, such as roof edges, eaves, and corners.

The use of a roll forming machine helps manufacturers produce these profiles efficiently and cost-effectively.

Drip Edge Roll Forming Machines are versatile and can be customized to produce various drip edge profiles to meet different roofing requirements.

They are known for their efficiency, precision, and the ability to produce high-quality drip edges in large quantities, making them essential equipment for roofing and construction companies.

Drip Edge Profiles

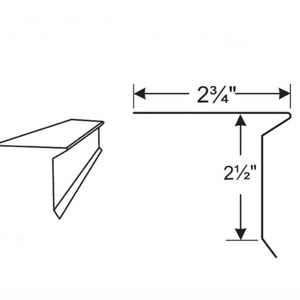

In the context of construction in the USA, a metal drip profile, also known as a drip edge or drip edge flashing, is a type of metal flashing used primarily in roofing applications.

Its main purpose is to direct water away from vulnerable areas of a roof, such as the edges, eaves, and corners, to prevent water from infiltrating the building structure and causing damage.

It's important to note that the specific features and capabilities of a Drip Edge Roll Forming Machine may vary depending on the manufacturer and model, so it's advisable to consult the machine's user manual and the manufacturer's specifications for detailed information about a particular machine

Typically, metal drip profiles are made from materials like galvanized steel, aluminum, or stainless steel, which are known for their durability and resistance to corrosion.

They come in various shapes and sizes, with L-shaped and T-shaped profiles being common options.

The specific design and requirements for drip edges may vary by local building codes and roofing practices.

I'm not sure if it's for you,but this product line has been selling like hot cakes in Philippines, Egypt, Saudi Arabia, Russia, India, Algeria, Middle East and other countries and regions .

You might want to dig into it a little bit. Contact me!!!

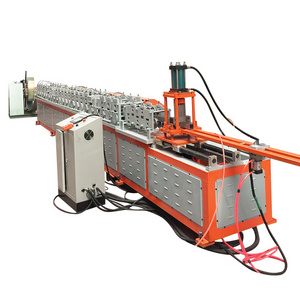

1.CD60/27 & UD27/28 2in 1 channel profile roll forming machine

C Stud and U Track channel 2 in 1 roll forming machine

2 in 1 u stud machine | 2 in 1 metal stud machine | U profile roll forming machine | U stud roll forming machine

To save space and price, some customer like to choose 2 in 1 roll forming machine, it means one machine can produce 2 shapes products. We can customize machine as your need, like

1. Omega profile and u channel 2 in 1 roll forming machine

2. Omega profile and angle bead 2 in 1 roll forming machine

3. Omega profile and C channel 2 in 1 roll forming machine

4. CD and UD 2 in 1 roll forming machine

5. C channel and angel bead 2 in 1 roll forming machine

6. Angle bead and u stud 2 in 1 roll forming machine

Product thickness common between 0.3-0.6 mm, we sell lots of such machine to Iraq, Egypt, UAE, Chile, Zambia, etc.

2.CD50/75/100 3in 1 channel profile roll forming machine

3 in 1 c channel machine | multiple c channel machine | C u channel roll forming machine

Multiple C channel machine popular sell in many countries, common thickness between 0.3-0.6 mm, Common speed 10-20 m/min, with servo motor speed can max reach to 30-50 m/min, we sell lots of such machine to Iraq, Egypt, UAE, Chile, Zambia, etc

3.Angle bead roll forming machine

Angle bead roll forming machine | Corner bead production line | Metal angle bead machine | Corner bead roll forming machine | V shape roll forming machine | Steel wall angle bar roll forming machine

Angle bead roll forming machine popular sell in many countries, size common include 20*20 mm, 25*25 mm, 27*27 mm, 30*30 mm. Product thickness common between 0.3-0.6 mm.

4.Omega furring channel roll forming machine

Omega profile roll forming machine | Omega channel roll forming machine | Omega channel roll forming machine | Top hat roll forming machine

Omega profile roll forming machine popular sell in many countries. Product thickness common between 0.3-0.6 mm, we sell lots of such machine to Iraq, Egypt, UAE, Chile, Zambia, etc

5.Small metal sheet line China disposable film slitting machine for aluminum coil

Its used for Omega , C channel ,Angle bead ,U track , metal stud profile sheet .

Slitting machine | metal slitter | sheet metal slitting machine | cheap sliting machine

Simple slitting machine control by motor, it can slitting to any width as your want, more flexible and easy operate. Price cheap, slitting machine width common include 1m, 1250mm, 1.5m, material use PPGI or GI material, thickness between 0.3-0.8 mm