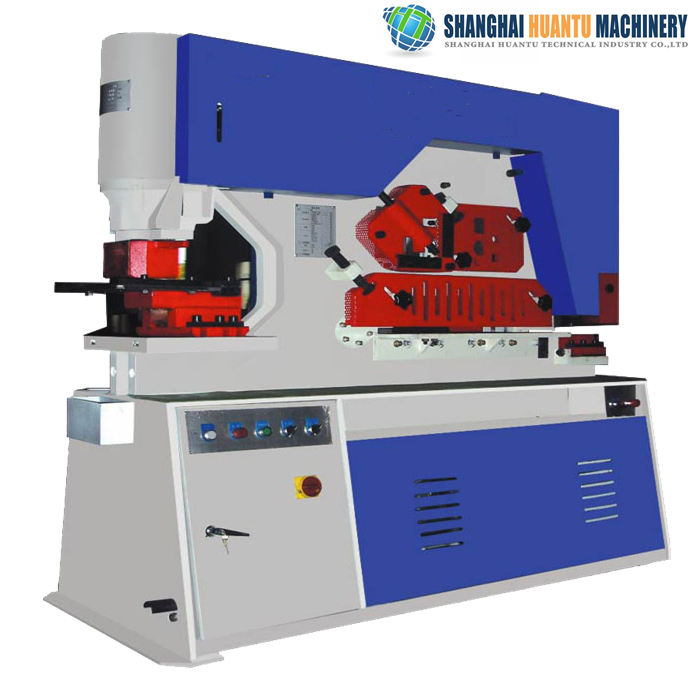

- Product Details

- {{item.text}}

Quick Details

-

Machine Color:

-

OEM

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Model Number:

-

Q35Y

-

Weight (T):

-

3

-

Machine Color:

-

OEM

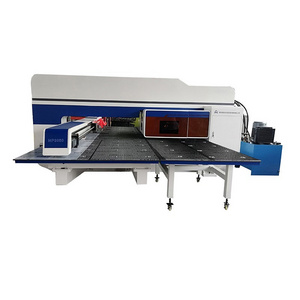

Hydraulic amada turret punch press , CNC amada turret punch press , amada turret punch press machine

1. Our steelworker has Robust and accurate steel frame

2. Our steelworker has Large punch table with scales

3. Our steelworker has Removable bolster for punching flanges and channel and beam

4. Our steelworker has 2 independent hydraulic cylinders

5. Our steelworker has 2 shielded foot controls

6. Our steelworker has 2 Separate Die Openings for oversized punching

7. Our steelworker has 5 working stations for wide applications

8. Our steelworker has power inching on all 5 work stations cutting machine

9. Our steelworker has plate shear support/table and notching table

10. Our steelworker has adjustable stroke controls with indicators on both cylinders

11. Our steelworker has punching machine: Movable work light

12. Our steelworker has overload protection on hydraulic system

13. Our steelworker has electric back gauge punching machine

14. Our steelworker has optional bending attachment cutting machine

15. Our steelworker has optional 5 sets punches and dies

|

Model |

Q35Y-16 ( IW-60 ) |

Q35Y-20 ( IW-90) |

Q35Y-25 (IW-110) |

Q35Y-30 ( IW-140) |

|

Working pressure(KN) |

600 |

900 |

1100 |

1400 |

|

Maxcutting thickness(mm) |

16 |

20 |

25 |

26 |

|

Maxcutting length(mm) |

400 |

480 |

600 |

600 |

|

Tensile strength of sheet metal (N/mm²) |

≤450 |

≤450 |

≤450 |

≤450 |

|

Shear angle(deg) |

7 |

8 |

8 |

8 |

|

Stroke of ram(mm) |

80 |

80 |

80 |

80 |

|

stroke times(min) |

8 |

8 |

8 |

8 |

|

Depth of throat(mm) |

300 |

355 |

400 |

600 |

|

Max Capacities(mm) |

25×16 |

30×20 |

35×25 |

38×28 |

|

Main motor(KW) |

4 |

5.5 |

7.5 |

11 |

|

Length of tool(mm) |

1650 |

1950 |

2355 |

2680 |

|

Width of tool(mm) |

800 |

900 |

980 |

1060 |

|

Height of tool(mm) |

1780 |

1930 |

2100 |

2350 |

|

Weight of tool(kg) |

1900 |

2600 |

4800 |

6800 |

|

PUNCHING METRIC(mm) |

||||

|

Max Capacities |

25×16 |

30×20 |

35×25 |

38×26 |

|

Max Stroke Length |

80 |

80 |

80 |

80 |

|

Throat Depth Standard |

305 |

355 |

400 |

600 |

|

Working Height |

1030 |

1084 |

1142 |

1209 |

|

SHEARING |

||||

|

Flat Bar |

250×16 |

330×20 |

300×25 |

355×30 |

|

Alternative |

400×8 |

480×10 |

600×16 |

600×20 |

|

Blade Length |

410 |

485 |

620 |

610 |

|

Working Height |

890 |

894 |

891 |

897 |

|

ANGEL CUTTING |

||||

|

At 90°cut |

125x125×12 |

140x140×12 |

160×160x14 |

200x200×12 |

|

At 45°Mitre |

70×10 |

70×10 |

70×10 |

70×10 |

|

Working Height |

1130 |

1139 |

1200 |

1220 |

|

SECTION CUTTING |

||||

|

Round/Square Bar |

45 |

50 |

60 |

65 |

|

Channel/I bar |

130×65 |

160×88 |

200x100 |

280×122 |

|

T bar |

90×12 |

90×12 |

90×12 |

90×12 |

|

NOTCHING |

||||

|

Material Thickness |

10 |

13 |

14 |

16 |

|

Width |

57 |

57 |

57 |

57 |

|

Depth: Vee -Rect. |

60-90 |

60-90 |

60-90 |

60-90 |

|

Working Height |

890 |

883 |

886 |

898 |

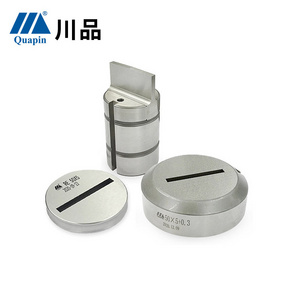

Components Options

Dies