- Product Details

- {{item.text}}

Quick Details

-

Design Style:

-

Modern

-

Product Type:

-

Vinyl Flooring

-

Place of Origin:

-

China

-

Brand Name:

-

TITAN

-

Model Number:

-

LVT Flooring

-

Surface Treatment:

-

Simple Color, UV Coating

-

Product Name:

-

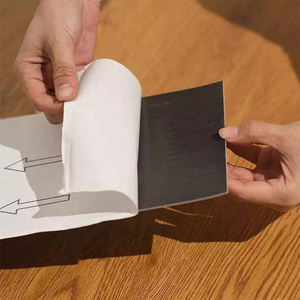

Self Adhesive LVT Flooring

-

Surface:

-

UV coating

-

Raw material:

-

Stone Plastic Vinyl, Stone Plastic Vinyl

-

Size:

-

7''x48''

-

Thickness:

-

3.5/4/5/6/7/8mm

-

Wear Layer:

-

0.3mm/0.5mm

-

Pattern:

-

Wood Grain, Stone and Carpet Look

-

Shrinkage Rate:

-

1‰

-

Feature:

-

Waterproof Wear Resistant Anti-slip

-

Certificate:

-

CE / SGS / ISO9001

Quick Details

-

After-sale Service:

-

Online technical support, Onsite Installation, Onsite Training, Onsite Inspection, Return and Replacement

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects

-

Application:

-

Hotel

-

Design Style:

-

Modern

-

Product Type:

-

Vinyl Flooring

-

Place of Origin:

-

China

-

Brand Name:

-

TITAN

-

Model Number:

-

LVT Flooring

-

Surface Treatment:

-

Simple Color, UV Coating

-

Product Name:

-

Self Adhesive LVT Flooring

-

Surface:

-

UV coating

-

Raw material:

-

Stone Plastic Vinyl, Stone Plastic Vinyl

-

Size:

-

7''x48''

-

Thickness:

-

3.5/4/5/6/7/8mm

-

Wear Layer:

-

0.3mm/0.5mm

-

Pattern:

-

Wood Grain, Stone and Carpet Look

-

Shrinkage Rate:

-

1‰

-

Feature:

-

Waterproof Wear Resistant Anti-slip

-

Certificate:

-

CE / SGS / ISO9001

Product Description

About TITAN SPC FLOORING

1, What is TITAN SPC Floor?

TITAN SPC Floor

is made of PVC resin, calcium powder, extruded by high temperature plasticizing, four roll calender, hot compress, color film decorative layer and wear-resistant layer, and water-cooled UV spray paint production line. It does not contain heavy metal formaldehyde and harmful substances.

2, Why do you choose

TITAN SPC Floor

?

TITAN SPC Floor

is more waterproof, environmental protection, Wear resistant, fire resistant and so on; Zero formaldehyde; High-strength click lock system for easy installation.

3.The application of

TITAN SPC Floor

?

It is widely used in family, hotels, shopping malls, schools, hospitals, office buildings, and other places' requirements.

|

Description

|

Vinyl FLOORING

|

|

Construction

|

SPC core(Limestone+Virgin PVC composite,not contain plasticizer) 2050 kgs/m3 density

|

|

Finish

|

Deep embossed,Hand scraped,Embossed in register,Marble

|

|

Wear Layer

|

0.3mm/0.5mm wear-layer for residential,light commercial&heavy commercial

|

|

Gloss Level

|

5%-7%

|

|

Profile

|

Angle installation,Drop and Lock

|

|

Edge

|

Micro-bevel edge,Painted bevel edge

|

|

Installation

|

Valinge,Unilin,Glue free

|

|

Warranty

|

15-20years

|

Production Process

Installation

Installation

Installation should begin with a corner and proceed from the wall with the tongue facing away from the wall. Allow a minimum gap of 3/8” (10mm) for product expansion. Transition moldings or baseboards will cover the gap.

When laying the first row in a straight line interlock the short ends by inserting the tongue into the grooves at an angle of about 15 to 20 degrees. Install sequential plank on the short end (5.75”) and be sure to line up evenly. Place this first row along the chosen wall respecting the minimum gap by using spacers.

Keep the seams tight between planks. You will feel and hear the click when locking the planks together to create a tight seam. There should be no visible gap between planks. If seams do not appear tight, pull the planks apart immediately and try again.

When installing our SPC, it is strongly suggested to stagger the rows so that the short edge seams are not in a straight uniform line.

To start the second row, measure and mark the plank, then using a straight edge and utility knife, score the plank and snap it.

Interlock the first plank of the second row again at a 15-20 degree angle. For the next planks, interlock the short side first, leaving it slightly away from the long side and then slide it into the long side in the same manner. Start the third row with the last plank remaining from the previous row.

Fitting around irregular objects is very easy with our SPC. Simply make a pattern out of heavy paper to fit around pipes or irregular objects. Place the pattern on the plank and trace. Cut along trace lines using a utility knife or heavy-duty scissors, and lay plank. Allow for expansion gaps along each wall. The humidity of a room can vary due to differences between the seasons. Therefore your SPC floor must be able to expand and contract in all directions. This expansion can amount to 2mm per meter (1/12 in. per 3.28 ft.), so the greater the surface area, the greater the room for expansion required. To allow for this variation, an 8-12 mm (5/16 in. -3/8in.) expansion gap is provided at all walls. A gap must also be provided around pipes or at thresholds or obstacle

Application

Related Products

Packing&Shipping

Company Introduction

FAQ

1. Q: What is your pvc vinyl floor warranty?

A: Our pvc vinyl floor is based on 100% virgin pvc material.

If you use for residential, we recommend 0.3 mm wear layer and the guaranty is 25 years.

If you use for commercial, we recommend 0.5 mm wear layer and the guaranty is 15 years.

2. Q: How can I know your flooring is consistent with your description?

A: Our principle is that Quality is first and free sample is available for your evaluation.

Before the production, we will also send you the production details sheet for your confirmation.

During the production, each step is strictly controlled by the QC team, and the Floor Score, CE Certificates and SGS can be send for your reference.

3. Q: What’s your MOQ? How many color I can choose?

The MOQ is one 20’ container with 4-6 colors from the E- catalog.

If your quantity is less than one container, you can also choose 500sqm per color from our stock color or 1000sqm from the E-catalog.

4. Q: Can you provide the floor accessories?

A: Yes. we also provide matching profiles such as skirting, EVA sheet or cork etc. We promise to offer you the one-stop services.

6. Q: Are samples available?

A: Of course. Free sample is available. You can choose the samples directly from our stock, or we can do the sample according to your required color design.

7. Q: What is the average production time? How can I get the flooring in time?

A: Our average production time is around 20~25 days. We have 4 modern lines to ensure your delivery time.

8. Q: Can you offer packing designs as per customers’ requests?

A: Of course. We can printed the package boxes as you required. If you need, we can send the popular designs for your reference.

9. Q: Can you OEM or ODM?

A: Yes, the products can be made according to your request.

10.Q: What kinds of payment methods do you accept? And how do you guarantee that I will get your PVC vinyl flooring after I pay?

A: Our payment term is 30% deposit and the balance will be received before shipping for FOB.

11.Q: How can I know the shipping cost and custom tax rate?

A: We keep collaborating with the well-known shipping company with rich clearance experience, we can show the detailed charge fee for you. And we also can offer the customer clearance service if you need.

12. Q: How I install your pvc vinyl floor?

A: The installation guide books and installation video can be sent to you.

13. Q: Can you provide the sample books to help my promotion?

A: Yes, we can design and offer the sample books to help your promotion. We believe that if you sell well, and then we sell well.

Hot Searches