- Product Details

- {{item.text}}

Quick Details

-

Seamless tube:

-

20G, A106B,A106C etc.

-

Longitudinally welded pipes:

-

235B,345B,X42,X52,X60,X70,X80 etc.

-

Alloy steel:

-

335P12,P22,P91,12Cr1MoVG, WB36 etc.

-

Color&Language:

-

Customized is available

-

Certification:

-

ISO9001:2015,CE

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

South Africa, Germany, Brazil, Pakistan, India, Russia, Thailand

Quick Details

-

Place of Origin:

-

Sichuan, China

-

Brand Name:

-

DUOLIN

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Field maintenance and repair service, Video technical support

-

Seamless tube:

-

20G, A106B,A106C etc.

-

Longitudinally welded pipes:

-

235B,345B,X42,X52,X60,X70,X80 etc.

-

Alloy steel:

-

335P12,P22,P91,12Cr1MoVG, WB36 etc.

-

Color&Language:

-

Customized is available

-

Certification:

-

ISO9001:2015,CE

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

South Africa, Germany, Brazil, Pakistan, India, Russia, Thailand

Pipe elbow induction bending machine

Detail

Technique P arameters:

|

Model |

MFP-100 |

MFP-160 |

MFP-200 |

MFP-300 |

MFP-400 |

MFP-600 |

|

Maximum Bending Angel |

180degree |

|||||

|

Bending Radius |

2D-6D/10D |

|||||

|

Bending Pipe Diameter |

159mm -219mm |

131mm -273mm |

159mm -325mm |

159mm -426mm |

168mm -610mm |

325mm -762mm |

|

Bending Pipe Wall Thickness |

5mm -20mm |

5mm -20mm |

5mm -25mm |

5mm -30mm |

5mm -30mm |

5mm -35mm |

|

Rated. Power Output |

100KW |

160KW |

200KW |

300KW |

400KW |

600KW |

|

Frequency |

1~5KHz |

1~5KHz |

1~5KHz |

1~8KHz |

1~4KHz |

1~4KHz |

|

Capacity of Power Source |

125KVA |

200KVA |

250KVA |

380KVA |

500KVA |

750KVA |

|

Power Input |

380V/50Hz 3-AC line |

|||||

|

Working Voltage |

340V-430V |

|||||

|

Input Current |

160A |

260A |

330A |

500A |

650A |

1000A |

|

Transformer |

800KVA |

1500KVA |

1500KVA |

3000KVA |

3000KVA |

5000KVA |

Feature:

1.All functions electrically controlled.

2.Keep temperature consistent inside the inductor during the bending process.

3.IGBT inversion technology & LC series circuit design achieve energy saving.

4.Diode rectification technology ensure high power factor –more than 0.95

5.Phase locking is employed to track frequency so that inverter operates safely and efficiently.

Application:

induction pipe bending machinery is perfect for these industries:

1. Highway billboards

2.Structure construction

3. Oil and gas (onshore and offshore) pipelines

4.Chemical and petrochemical

5.. Power generation

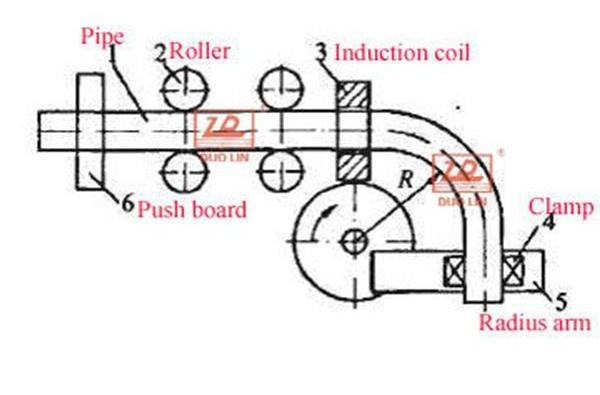

Advantage of induction bending:

induction pipe bending machinery provides highly accurate bends, good quality and cost savings.

1. Uniform temperature during induction heating and cooling ensures that the pipe's physical properties are maintained or improved.

2. Not require sand filling and internal mandrels

3. Bending times do not take as long as other processes, making induction bending more cost effective.

4. Can produce multiple bends

5. Lower installation cost, improved flow and reduced operating cost.

6. Superior quality at ovality and wall thinning

1. Reply the email within 24hours. 6 staffs work for Export Department,

2. Two of them who have experience in sales, installing and after-service more than 7 years.

3. on-site engineering service

4. 12 months warranty

5. Color, language and logo can be printed according to your demands.

6. Plywood cases customized for sea transport.