- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

Hot Product

-

Core Components:

-

Machine tool, Electric machine, Rack drive dual drive

-

Application:

-

cotton, linen

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

Perfect Laser

-

Dimension(L*W*H):

-

3100mm*7800mm *2400mm

-

Weight:

-

3000 KG

-

Features:

-

Cloth Cutting

-

Cutting method:

-

Tool repeating up and down cutting

-

Cutting speed (mm/min):

-

15-40 m/min

-

Machine running speed (mm/min):

-

50-60000 mm/min

-

Set speed error (%):

-

≤±5%

-

Cutting accuracy:

-

≤±1.0 mm

-

Straightness:

-

0.5 mm

-

Machine Draw-line accuracy:

-

≤0.5 mm

-

Surrounding environment:

-

Ventilation, no big impact

-

Power Supply:

-

220V / 380V±10%

-

Input power:

-

<30KW

Quick Details

-

Production Capacity:

-

30sets/month

-

Voltage:

-

380V/220V

-

Machinery Test Report:

-

Provided CE Certificate

-

Marketing Type:

-

Hot Product

-

Core Components:

-

Machine tool, Electric machine, Rack drive dual drive

-

Application:

-

cotton, linen

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

Perfect Laser

-

Dimension(L*W*H):

-

3100mm*7800mm *2400mm

-

Weight:

-

3000 KG

-

Features:

-

Cloth Cutting

-

Cutting method:

-

Tool repeating up and down cutting

-

Cutting speed (mm/min):

-

15-40 m/min

-

Machine running speed (mm/min):

-

50-60000 mm/min

-

Set speed error (%):

-

≤±5%

-

Cutting accuracy:

-

≤±1.0 mm

-

Straightness:

-

0.5 mm

-

Machine Draw-line accuracy:

-

≤0.5 mm

-

Surrounding environment:

-

Ventilation, no big impact

-

Power Supply:

-

220V / 380V±10%

-

Input power:

-

<30KW

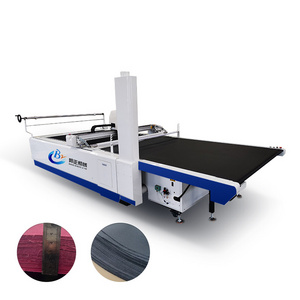

Perfect Laser- fully Automatic fabric cutting machine Vibrating knife automatic multi-layer cloth cutting machine

Model:(

PE-B2033

)

Contact: Sara +8613971657490 Email:sales021(@)perfectlaser.net

Product Introduction

Perfect laser has been specialized in various types of industrial equipment research and development for many years and accumulated much industry experience. Perfect laser is always devoting to offer cost-effective products to our dear customers.

This newly developed automatic fabric cutting machine PEMB-2033 is an intelligent automatic fabric cutting machine, which replace the traditional cutting (hand scissors, electric clippers) successfully solving problems such as high labor cost, large material

waste, low productivity. Typesetting automatically, material saving, high cutting precision, high production efficiency.

This newly developed automatic fabric cutting machine PEMB-2033 is an intelligent automatic fabric cutting machine, which replace the traditional cutting (hand scissors, electric clippers) successfully solving problems such as high labor cost, large material

waste, low productivity. Typesetting automatically, material saving, high cutting precision, high production efficiency.

Machine Details

The Features of

CNC Multi-Layer Auto Fabric Cutter

1. The material discharging system is designed by the computer, manual and computer automatically and effectively combined to improve the efficiency of discharge, ordinary personnel as long as they are familiar with computer operation. As long as the ordinary personnel are familiar with the computer operation, they can master the material discharging skills skillfully.

2. Automatic fabric cutting machine can realize zero-spacing cutting and effectively save raw materials; Automatic cutting controlled by computer, instead of a large number of cutting workers, to achieve mass production;

3. The cutting precision is high, the lathe can directly sew the seam without trimming the pieces, effectively improving the sewing efficiency of the lathe;

4. The cutting bed control software supports multi-source data format: user can directly receive common clothing design and type setting the software;

5. The unique algorithm and motion control technology can realize the seamless connection between the straight line and the arc line, with high cutting precision;

6. A utomatic fabric cutting machine adopts automatic knife sharpening technology, the sharpening time can be designed according to the characteristics of the fabric, therefore, it effectively extends the service life of the cutting knife;

7. New high-efficiency energy-saving pump design, can reduce working noise. In the same performance situation, reducing power and saving energy;

8. Adopts long-life mane brick cutting platform design, the cutting knife can penetrate the surface without damage;

9. For picking area, the conveyors can be operated independently or synchronously.

2. Automatic fabric cutting machine can realize zero-spacing cutting and effectively save raw materials; Automatic cutting controlled by computer, instead of a large number of cutting workers, to achieve mass production;

3. The cutting precision is high, the lathe can directly sew the seam without trimming the pieces, effectively improving the sewing efficiency of the lathe;

4. The cutting bed control software supports multi-source data format: user can directly receive common clothing design and type setting the software;

5. The unique algorithm and motion control technology can realize the seamless connection between the straight line and the arc line, with high cutting precision;

6. A utomatic fabric cutting machine adopts automatic knife sharpening technology, the sharpening time can be designed according to the characteristics of the fabric, therefore, it effectively extends the service life of the cutting knife;

7. New high-efficiency energy-saving pump design, can reduce working noise. In the same performance situation, reducing power and saving energy;

8. Adopts long-life mane brick cutting platform design, the cutting knife can penetrate the surface without damage;

9. For picking area, the conveyors can be operated independently or synchronously.

Specification

|

Model

|

PE-B2033

|

|

Effective cutting width (mm)

|

2000

|

|

Effective cutting length (mm)

|

3300

|

|

Fabric cutting thickness (after vacuum adsorption) (mm)

|

70 mm

|

|

Cutting method

|

Tool repeating up and down cutting

|

|

Cutting speed (mm/min)

|

15-40 m/min

|

|

Machine running speed (mm/min)

|

50-60000 mm/min

|

|

Set speed error (%)

|

≤±5%

|

|

Cutting accuracy

|

≤±1.0 mm

|

|

Intersection offset

|

1.0 mm

|

|

Straightness

|

0.5 mm

|

|

Roundness

|

1.0 mm

|

|

Diagonal difference

|

1.0 mm

|

|

Repeat Accuracy

|

0.5 mm

|

|

Machine Draw-line accuracy

|

≤0.5 mm

|

QC & Delivery

Hot Searches