This printing machine is offset printing machine , mainly used for printing words, logo and trademarkt on woven bag/ kfraft bag/nonwoven bag as well as carton box , It can finish multicolor printing at one time. The machine structure is simple, easy operation and maintenance, high precision of registering, It has automatic counter, fine adjustment and photoelectric automatic printing function. bag printing machine adopts photo electricity control, electromagnetic regulating, automatic imprinting on-off device, electronic automatic numerating.The power adapts stepless speed control in order to reach stable operation and wide speed control range.

- Product Details

- {{item.text}}

Quick Details

-

Dimensions(L*W*H):

-

2000x1400x1100mm

-

Weight:

-

800 KG

-

Product name:

-

woven bag printing machine

-

Printing material:

-

Paper Bag woven bag

-

Application:

-

Flexible Package Printing

-

Printing speed:

-

10~80m/min

-

Printing length:

-

1200mm

-

Printing Width:

-

650mm

-

Printing colors:

-

2 colors

-

After-sales service:

-

Service Machinery Overseas

-

Paper gsm:

-

250-350gsm

-

Power:

-

3.5kw

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Lukes

-

Voltage:

-

380/220V

-

Dimensions(L*W*H):

-

2000x1400x1100mm

-

Weight:

-

800 KG

-

Product name:

-

woven bag printing machine

-

Printing material:

-

Paper Bag woven bag

-

Application:

-

Flexible Package Printing

-

Printing speed:

-

10~80m/min

-

Printing length:

-

1200mm

-

Printing Width:

-

650mm

-

Printing colors:

-

2 colors

-

After-sales service:

-

Service Machinery Overseas

-

Paper gsm:

-

250-350gsm

-

Power:

-

3.5kw

One Color Flexographic Printer Woven Bag Shopping Bag Printer Paper Bag Printing Machine With Flexo Printing

TWO SIDE WOVEN BAG PRINTING MACHINE

|

Model

|

LKSBP850

|

|

Printing colors number

|

3

|

|

Power

|

1.1 kw

|

|

Printing capacity

|

1000-2000 pcs/h

|

|

Max.input width

|

800 mm

|

|

Max. printing width

|

650 mm

|

|

Max. printing length

|

1200 mm

|

|

Thickness of plastic cylinder

|

4-6 mm

|

|

Roller thickness

|

10 mm

|

|

Dimension

|

2400*1350*1150 mm

|

|

Weight

|

800 kg

|

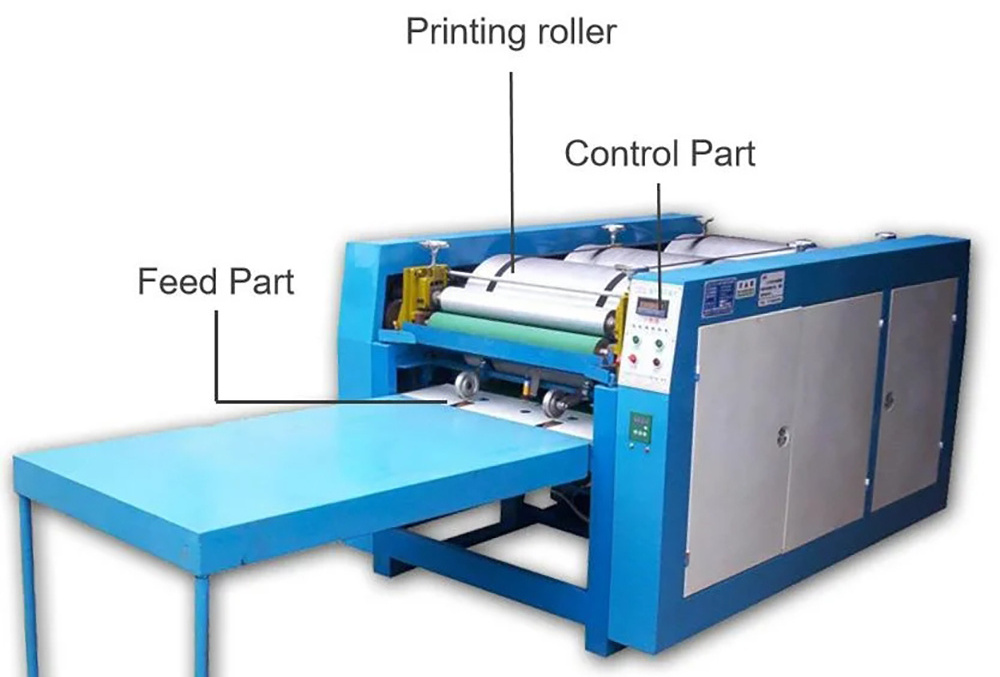

Feed Part

The roller setting of the bags printing machine is convenient for feeding. Smooth and high efficiency.

Control Part

The printer machine is easy to operate, and the printing quantity can be set according to the requirements.

Printing Part

Anilox roller is used to transfer ink, which makes the ink color uniform and enhances the printing smoothness

Machine Material Display

The bags printing machine is made of high-quality materials and is durable. Compared with other brands of machines, the equipment

failure rate is very low.

failure rate is very low.

Hot Searches