- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

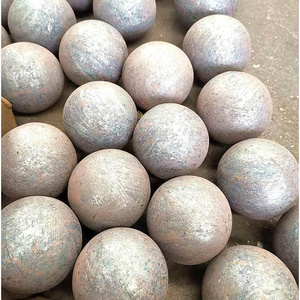

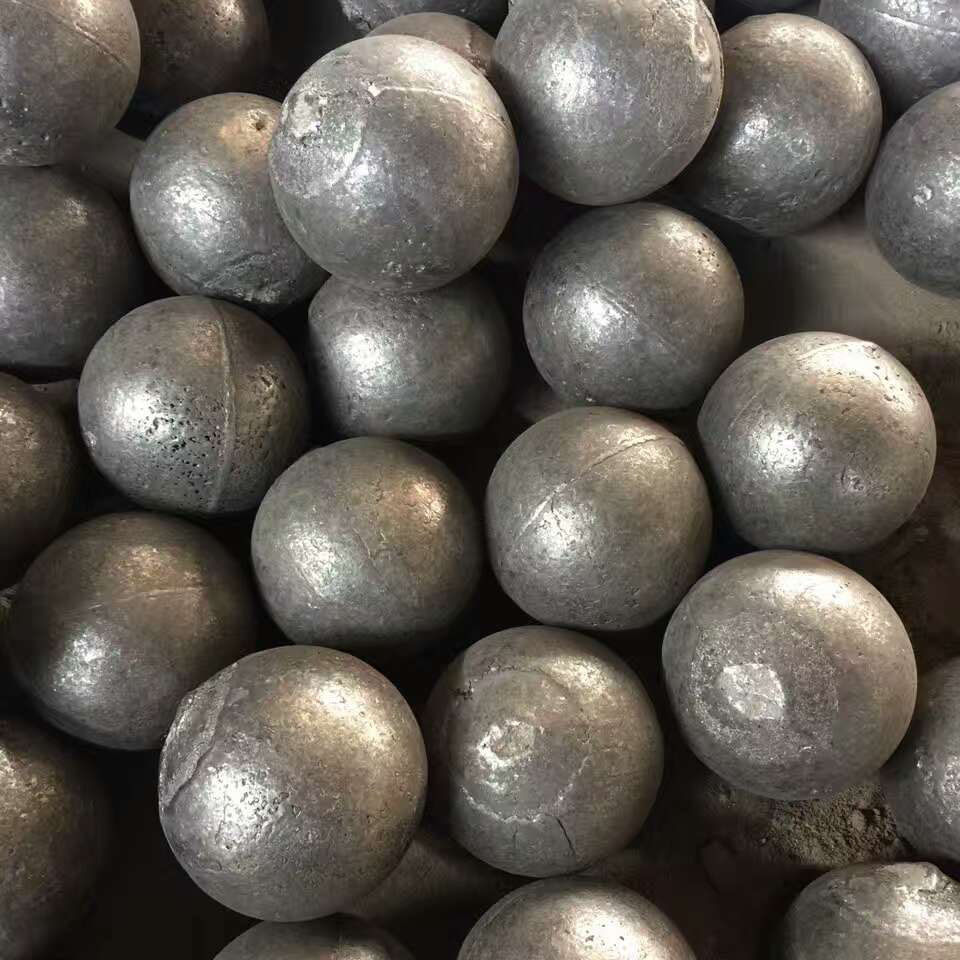

high chrome grinding media steel ball

-

Diameter:

-

8-150mm

-

Breakage rate:

-

<1%

-

Hardness:

-

≥55HRC

-

Impact valve:

-

≥12J/cm^2

-

Drop times:

-

≥12000times

-

Microstructure:

-

M+C

-

Material:

-

iron,Steel

-

Application:

-

Mine And Ball Mill

-

Certificate:

-

ISO9001

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HF

-

Model Number:

-

1/3-6inch

-

Product name:

-

high chrome grinding media steel ball

-

Diameter:

-

8-150mm

-

Breakage rate:

-

<1%

-

Hardness:

-

≥55HRC

-

Impact valve:

-

≥12J/cm^2

-

Drop times:

-

≥12000times

-

Microstructure:

-

M+C

-

Material:

-

iron,Steel

-

Application:

-

Mine And Ball Mill

-

Certificate:

-

ISO9001

Our company mainly produces 8 mm-1 50mm low, middle, high chrome alloy casting iron ball. Huafu chose large angle steel, scrap steel and other raw material, according to different product, needs adding chrome, manganese, vanadium, titanium, rare earth and as so on metal. Products high hardness, low wear, good toughness and less broken, in the process of using sphere will further improve the surface hardness, wear resistance.

Chrome alloy casting iron ball are widely used in cement, buildingmaterials, metal mining, coal slurry thermal power, chemical engineering, ceramic coating, light industry, papermaking, ultrafine powder preparation of magnetic materials and other industries and further processing.

Chemical composition

| Name | Brand | Chemical composition(%) | ||||||||

| C | Si | Mn | Cr | Mo | Cu | Ni | P | S | ||

| Chrome alloy casting iron ball | ZQCr26 | 2.0-3.3 | 1.2max | 0.3-1.5 | >23.0-30.0 | 0-3.0 | 0-1.2 | 0-1.5 | ≤0.10 | ≤0.06 |

| ZQCr20 | 2.0-3.3 | 1.2max | 0.3-1.5 | >18.0-23.0 | 0-3.0 | 0-1.2 | 0-1.5 | ≤0.10 | ≤0.06 | |

| ZQCr15 | 2.0-3.3 | 1.2max | 0.3-1.5 | >14.0-18.0 | 0-3.0 | 0-1.2 | 0-1.5 | ≤0.10 | ≤0.06 | |

| ZQCr12 | 2.0-3.3 | 1.2max | 0.3-1.5 | >10.0-14.0 | 0-3.0 | 0-1.2 | 0-1.5 | ≤0.10 | ≤0.06 | |

| ZQCr8 | 2.1-3.3 | 2.2max | 0.3-1.5 | 7.0-10.0 | 0-1.0 | 0-0.8 | - | ≤0.10 | ≤0.06 | |

| ZQCr5 | 2.1-3.3 | 1.5max | 0.3-1.5 | 4.0-6.0 | 0-1.0 | 0-0.8 | - | ≤0.10 | ≤0.10 | |

| ZQCr2 | 2.1-3.6 | 1.5max | 0.3-1.5 | 1.0-3.0 | 0-1.0 | 0-0.8 | - | ≤0.10 | ≤0.10 | |

Technical specification

| Name | Brand | Diameter(mm) | Hardness(HRC) | Breakage rate | Impact value(J/cm²) | Drop times | Micro structure |

| Chrome alloy casting iron ball | ZQCr26 | 17-150 | >58 | <1% | >7 | ≥12000 | M+C |

| ZQCr20 | 17-150 | >58 | <1% | >6 | ≥12000 | M+C | |

| ZQCr15 | 17-150 | >58 | <1% | >5 | ≥12000 | M+C | |

| ZQCr12 | 17-150 | >58 | <1% | >3.5 | ≥12000 | M+C | |

| ZQCr8 | 17-150 | >58 | <1% | >3 | ≥12000 | M+C | |

| ZQCr5 | 17-150 | >47 | <1% | >2 | ≥10000 | M+C | |

| ZQCr2 | 17-150 | >45 | <1% | >1.5 | ≥8000 | P+C |

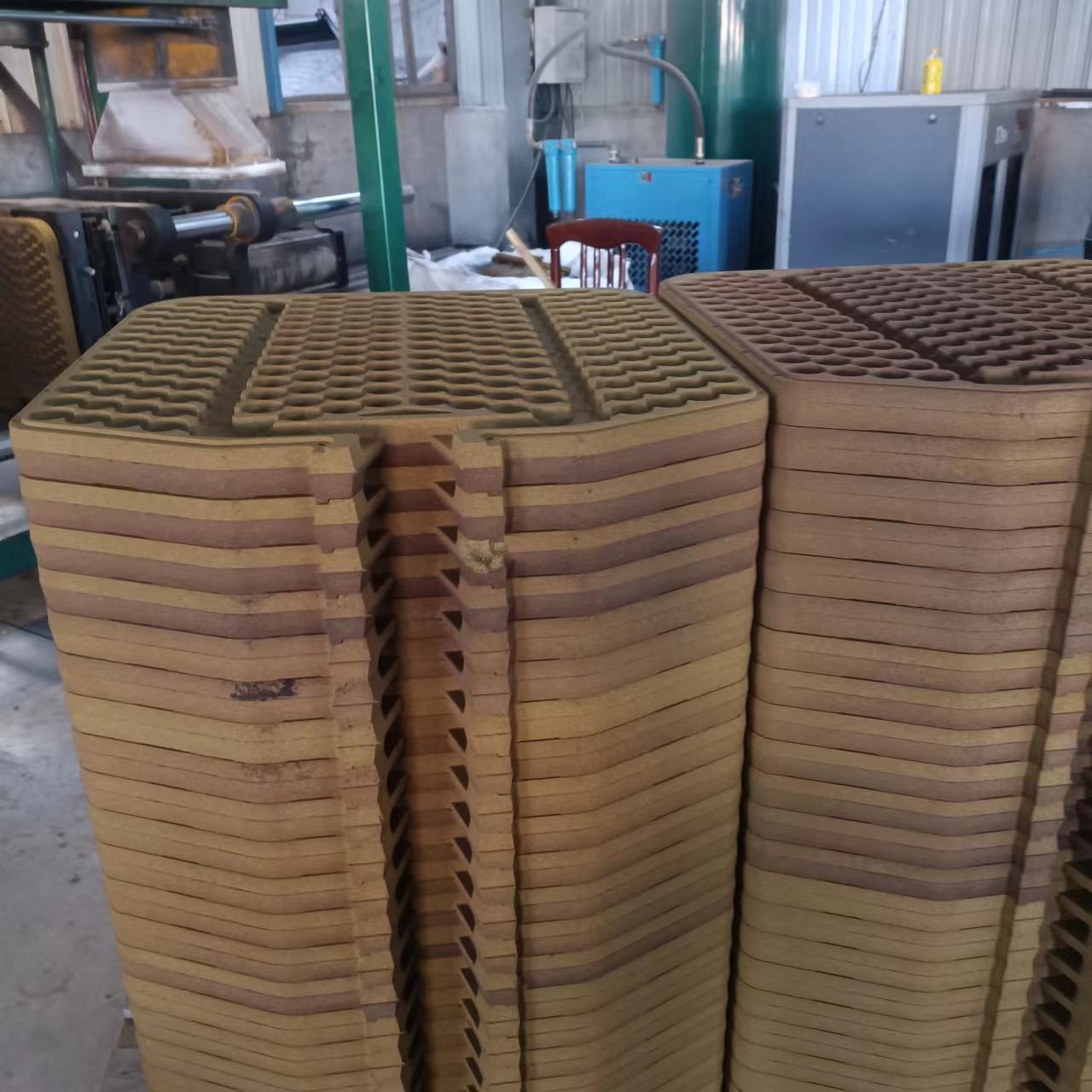

Production process of Chrome alloy casting iron ball:

Raw material→Secientic proportioning→Electric furnace smelting→Assay before furnace→Mould forming→Polishing→Heat treatment→Packing

Packaging & Shipping