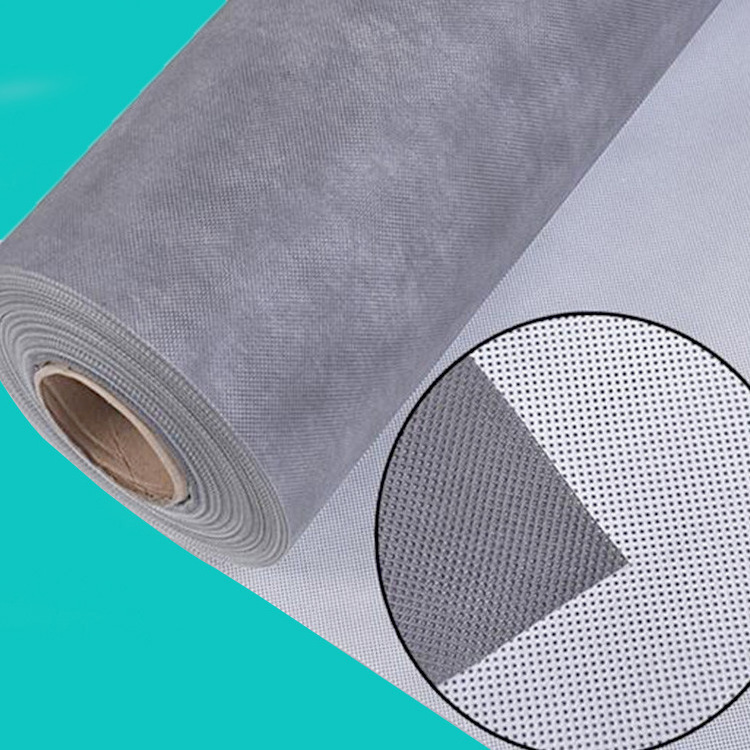

PVC waterproof coil is a thermoplastic PVC coil. The polymer coil is made of polyester fiber fabric as reinforcement, and the

polyvinyl plastic layer on both sides is combined with the polyester reinforcement in the middle by a special extrusion coating

process

- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Office Building

-

Design Style:

-

Contemporary

-

Place of Origin:

-

Yun Nan

-

Brand Name:

-

XINC

-

Model Number:

-

FG360+

-

Type:

-

waterproof coil membrane

-

Product Name:

-

PVC waterproofing membrane

-

Material:

-

poly vinyl chloride

-

Keyword:

-

PVC Waterproof Mambrane

-

Thickness:

-

1.2mm 1.5mm 1.8mm 2.0mm

-

Function:

-

waterproof

-

Standard:

-

GB 12952-2011

-

Advantage:

-

Weather resistance,corrosion resistance

-

Surface material:

-

woven fabric

-

Certificate:

-

CE

-

life time:

-

10

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Online technical support, Onsite Installation, Onsite Training, Onsite Inspection, Free spare parts, Return and Replacement, Other

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation, NONE

-

Application:

-

Office Building

-

Design Style:

-

Contemporary

-

Place of Origin:

-

Yun Nan

-

Brand Name:

-

XINC

-

Model Number:

-

FG360+

-

Type:

-

waterproof coil membrane

-

Product Name:

-

PVC waterproofing membrane

-

Material:

-

poly vinyl chloride

-

Keyword:

-

PVC Waterproof Mambrane

-

Thickness:

-

1.2mm 1.5mm 1.8mm 2.0mm

-

Function:

-

waterproof

-

Standard:

-

GB 12952-2011

-

Advantage:

-

Weather resistance,corrosion resistance

-

Surface material:

-

woven fabric

-

Certificate:

-

CE

-

life time:

-

10

Product Description

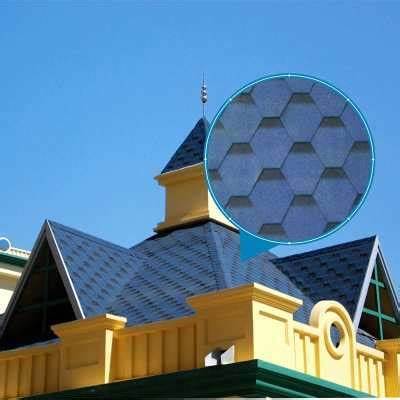

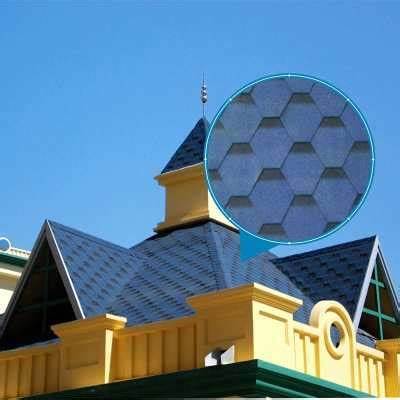

XINC corrosion resistant Fibre-reinforced Version PVC L waterproofing membrane for pool/flat roof

Recommended reasons: weather resistance, corrosion resistance

Features of

XINC corrosion resistant Fibre-reinforced Version PVC Waterproof Roofing Membrane for pool/flat roof

* PVC waterproof coil has high tensile strength, good elongation and small thermal size change rate

* With good weldability, the joint becomes one with the base material after hot air welding

* With good water vapor diffusion, condensate is easy to release, moisture left to the base, moisture is easy to discharge

* Aging resistance, UV resistance, chemical corrosion resistance, root penetration resistance

* Good flexibility at low temperature (-20℃). Long service life and no environmental pollution

* The surface of the color reflects ultraviolet radiation, and the surface of the PVC waterproof coil absorbs less heat and has low temperature

* Excellent flexibility and extensibility, high tensile strength, excellent dimensional stability, high mechanical strength, corrosion resistance, root penetration resistance, weather resistance and UV resistance linear, hail resistance

* With good weldability, the joint becomes one with the base material after hot air welding

* With good water vapor diffusion, condensate is easy to release, moisture left to the base, moisture is easy to discharge

* Aging resistance, UV resistance, chemical corrosion resistance, root penetration resistance

* Good flexibility at low temperature (-20℃). Long service life and no environmental pollution

* The surface of the color reflects ultraviolet radiation, and the surface of the PVC waterproof coil absorbs less heat and has low temperature

* Excellent flexibility and extensibility, high tensile strength, excellent dimensional stability, high mechanical strength, corrosion resistance, root penetration resistance, weather resistance and UV resistance linear, hail resistance

Application

1,Waterproofing of industrial and civil building surfaces and side walls;

2,Planting roof waterproofing works

3,Underground structures, subway stations, tunnels and other waterproofing works

4,Roads, Bridges, railways and other waterproofing projects, DAMS, water conservancy facilities and other waterproofing projects

2,Planting roof waterproofing works

3,Underground structures, subway stations, tunnels and other waterproofing works

4,Roads, Bridges, railways and other waterproofing projects, DAMS, water conservancy facilities and other waterproofing projects

key points of construction

1, full adhesive method: Before the construction of waterproof coil, first lay the coil on the base surface, respectively, brush the adhesive on the fold of the substrate surface, and so on, when the adhesive is not sticky to the hand, the pre-laid waterproof coil surfaceCarry out adhesive compaction, and then carry out joint welding construction. The surface is closed and glued and

compacted with a press roll. Fold the unfolded part, continue to use the above method for full bonding, and weld the lap joint.

compacted with a press roll. Fold the unfolded part, continue to use the above method for full bonding, and weld the lap joint.

2,Empty paving method: First lay in accordance with the laying method of the full adhesion method, and then the overall waterproof

project around the coil for full adhesion, and welded lap joints

project around the coil for full adhesion, and welded lap joints

Specification

|

item

|

value

|

|

Warranty

|

1 Year

|

|

After-sale Service

|

Online technical support, Onsite Installation, Onsite Training, Onsite Inspection, Free spare parts, Return and Replacement, Other

|

|

Project Solution Capability

|

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation, NONE

|

|

Application

|

Office Building

|

|

Design Style

|

Contemporary

|

|

Place of Origin

|

Yun Nan

|

|

Brand Name

|

XINC

|

|

Model Number

|

FG360+

|

|

Type

|

waterproof coil membrane

|

|

Product Name

|

PVC waterproofing membrane

|

|

Material

|

poly vinyl chloride

|

|

Keyword

|

PVC Waterproof Mambrane

|

|

Thickness

|

1.2mm 1.5mm 1.8mm 2.0mm

|

|

Function

|

waterproof

|

|

Standard

|

GB 12952-2011

|

|

Advantage

|

Weather resistance,corrosion resistance

|

|

Surface material

|

woven fabric

|

|

Certificate

|

CE

|

|

life time

|

10

|

|

No.

|

Item ( FG360PVC waterproof coil (innovative material )

|

|

Indictor

|

|

|

|

|

|||||

|

|

|

|

H

|

L

|

P

|

G

|

GL

|

|||||

|

1

|

Thickness of working layer above intermediate fetal base/mm

|

|

|

|

0.4

|

|

|

|||||

|

2

|

tensile property

|

maximum tension(N/cm)≥

|

|

120

|

250

|

|

120

|

|||||

|

|

|

tensile strength/Mpa≥

|

10

|

|

|

10

|

|

|||||

|

|

|

Elongation at maximum tension/%

|

|

15

|

|

|

|

|||||

|

|

|

elongation at break/%≥

|

200

|

150

|

|

200

|

100

|

|||||

|

3

|

Heat treatment size change rate/%≤

|

|

2

|

1

|

0.5

|

0.1

|

0.1

|

|||||

|

4

|

Low temperature flexability

|

|

﹣25℃ no crack

|

|

|

|

|

|||||

|

5

|

unpermeability

|

|

0.3MPa,2h no leak water

|

|

|

|

|

|||||

|

6

|

impact resistance

|

|

0.5kg.m no leak water

|

|

|

|

|

|||||

|

7

|

Antistatic load/a

|

|

|

|

20kg water no leakage

|

|

|

|||||

|

8

|

Direct peel strength(N/mm)≥

|

|

4.0 or coild damaged

|

|

3

|

|

|

|||||

|

9

|

Right-angle tearing strength(N/mm)≥

|

|

50

|

|

50

|

|

|

|||||

|

10

|

Trapezoidal tearing strength /N ≥

|

|

|

150

|

250

|

|

220

|

|||||

|

11

|

water absorption(70℃,168h)/%

|

After soaking

|

4

|

|

|

|

|

|||||

|

|

|

After airing

|

﹣0.4

|

|

|

|

|

|||||

|

12

|

thermal ageing (80℃)

|

time/h

|

672

|

|

|

|

|

|||||

|

|

|

appearance

|

No bubbles, cracks, delamination, bonding and holes

|

|

|

|

|

|||||

|

|

|

Maxi. tensile retention/%≥

|

|

85

|

85

|

|

85

|

|||||

|

|

|

Tensile strength retention rate/%≥

|

85

|

|

|

85

|

|

|||||

|

|

|

Elongation retention rate at maxi. tension/%≥

|

|

|

80

|

|

|

|||||

|

|

|

Elongation at break retention rate/%≥

|

80

|

80

|

|

80

|

80

|

|||||

|

|

|

Low temperature flexability

|

﹣20℃no crack

|

|

|

|

|

|||||

|

13

|

chemical resistance

|

appearance

|

No bubbles, cracks, delamination, bonding and holes

|

|

|

|

|

|||||

|

|

|

Maxi. tensile retention/%≥

|

|

85

|

85

|

|

85

|

|||||

|

|

|

Tensile strength retention rate/%≥

|

85

|

|

85

|

|

|

|||||

|

|

|

Elongation retention rate at maxi. tension/%≥

|

|

|

80

|

|

|

|||||

|

|

|

Elongation at break retention rate/%≥

|

80

|

80

|

|

80

|

80

|

|||||

|

|

|

Low temperature flexability

|

﹣20℃ no crack

|

|

|

|

|

|||||

|

14

|

artificial weathering test

|

time/h

|

1500/b

|

|

|

|

|

|||||

|

|

|

appearance

|

No bubbles, cracks, delamination, bonding and holes

|

|

|

|

|

|||||

|

|

|

Maxi. tensile retention/%≥

|

|

85

|

85

|

|

85

|

|||||

|

|

|

Tensile strength retention rate/%≥

|

85

|

|

85

|

|

|

|||||

|

|

|

Elongation retention rate at maxi. tension/%≥

|

|

|

80

|

|

|

|||||

|

|

|

Elongation at break retention rate/%≥

|

80

|

80

|

|

80

|

80

|

|||||

|

|

|

Low temperature flexability

|

﹣20℃ no crack

|

|

|

|

|

|||||

Packing & Delivery

10 Square Meters Packed in 1 Roll

Packaging and storage:

* Storage: Coil should be placed in a cool and dry warehouse, avoid direct sunlight, away from the fire source. The coil should not exceed 5 layers when placed horizontally, and should be stacked in a single layer when placed vertically. Contact with acids, alkalis, oils and organic solvents is prohibited. The storage temperature should not be higher than 45℃. Under normal conditions, the storage time is 1 year

* Transport: prevent tilt or transverse pressure, and do external protection

* Storage: Coil should be placed in a cool and dry warehouse, avoid direct sunlight, away from the fire source. The coil should not exceed 5 layers when placed horizontally, and should be stacked in a single layer when placed vertically. Contact with acids, alkalis, oils and organic solvents is prohibited. The storage temperature should not be higher than 45℃. Under normal conditions, the storage time is 1 year

* Transport: prevent tilt or transverse pressure, and do external protection

Hot Searches