- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

CHOVYTING

-

Model Number:

-

CW500V

-

Voltage:

-

380/220V 50/60HZ

-

Dimension(L*W*H):

-

9000*1350*1800mm

-

Weight:

-

2900 KG

-

Product name:

-

Polythene used plastic shopping bag making machine

-

Servo motor:

-

Yaskawa Japan

-

Inverter:

-

Yaskawa Japan

-

PLC:

-

PANASONC JAPAN

-

Touch screen:

-

Taiwan

-

Photocell:

-

SICK Germany

-

Switch and button:

-

IDEC Japan

-

Cylinder:

-

SHAKO Taiwan

-

Operation Language:

-

English/Russia/Arabic/Spanish /Chinese

-

Certification:

-

CE/SGS/ISO9001

Quick Details

-

Machine Type:

-

Bag Forming Machine

-

Bag Type:

-

T-shirt Bag

-

Material:

-

Plastic

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

CHOVYTING

-

Model Number:

-

CW500V

-

Voltage:

-

380/220V 50/60HZ

-

Dimension(L*W*H):

-

9000*1350*1800mm

-

Weight:

-

2900 KG

-

Product name:

-

Polythene used plastic shopping bag making machine

-

Servo motor:

-

Yaskawa Japan

-

Inverter:

-

Yaskawa Japan

-

PLC:

-

PANASONC JAPAN

-

Touch screen:

-

Taiwan

-

Photocell:

-

SICK Germany

-

Switch and button:

-

IDEC Japan

-

Cylinder:

-

SHAKO Taiwan

-

Operation Language:

-

English/Russia/Arabic/Spanish /Chinese

-

Certification:

-

CE/SGS/ISO9001

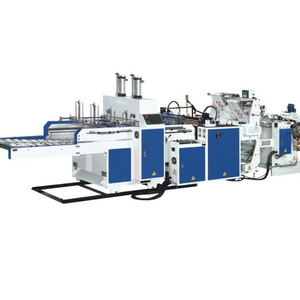

Brief Introduction

This is a practical high yield single line T-shirt bag making machine.Fully automatic operation,customers can effectively reduce the cost of investment and labor workforce.

Main Features

1)Single line width range practical design.

2)Unwinding tension adopts fully automatic tension control.

3)Unwinding roll with big diameter option save material changing time.

4)With feeding automatic correction design.

5)New design of punch device,able to adapt to a longer length of t-shirt bag.

Optional

1.Single sheet film folding unit(hydraulic auto loading device)

2.Double sealing knife device

3.Bottom sealing knife device

|

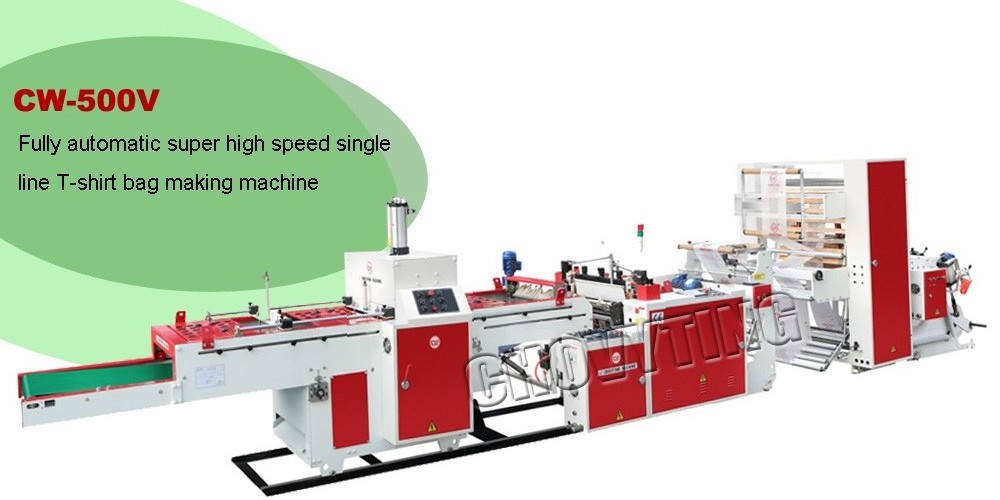

Model

|

CW-500V

|

CW-600V

|

|

Bag length

|

370-1200mm

|

370-1200mm

|

|

Bag width

|

500mm

|

600mm

|

|

Line speed

|

100m/min

|

100m/min

|

|

Speed of bag-making

|

220pcs/min

|

200pcs/min

|

|

Total power

|

about9.8KW

|

about10.5KW

|

|

Machine weight

|

2900kg

|

3100kg

|

|

Overall dimension (LXWXH)

|

9000*1350*1800mm

|

9000*1450*1800mm

|

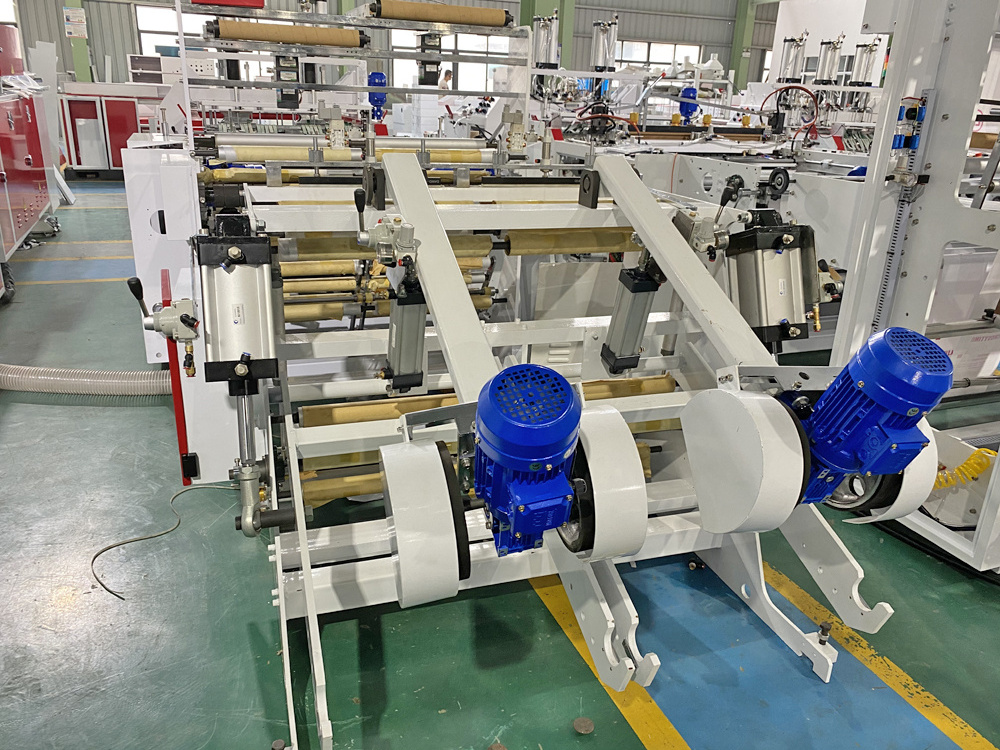

1.Unwinder adopts air cylinder automatic load design.

2.Unwinding shaft adopts heavy-chain air shaft.

3.Adopts AC frequency motor driving constant tension control,feeding speed is according to the producing speed.

4.Unwinder part has the EPC and automatic tension control.

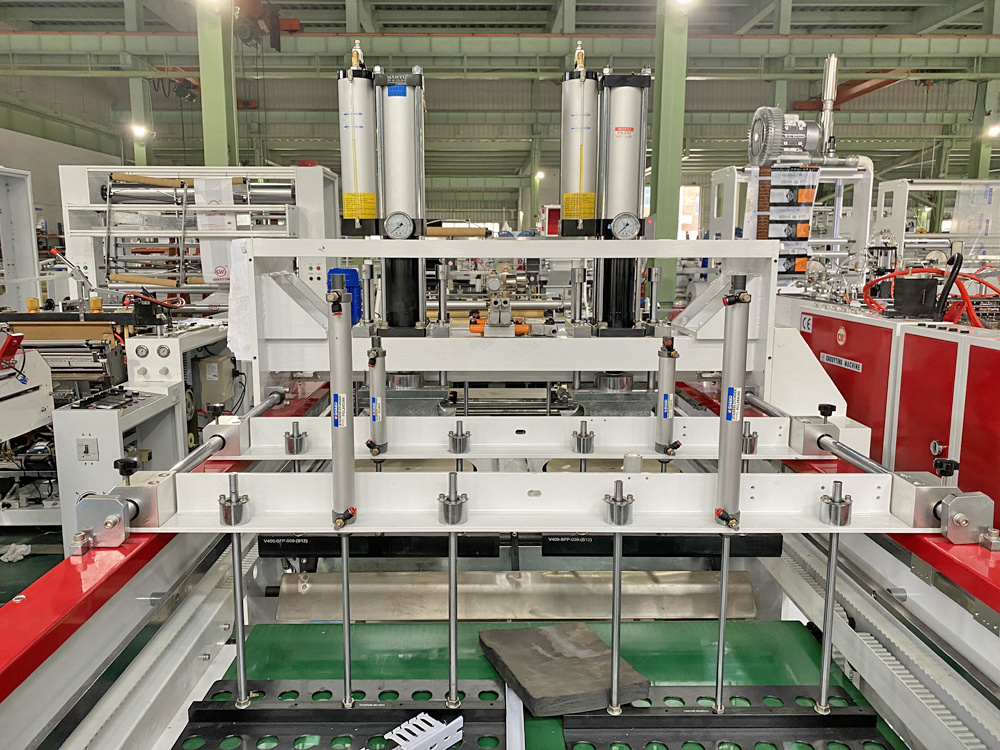

1.With 5tons hydraulic air cylinder punch from Taiwan.

2.The motor of clip for clamp the bag is Ac inverter motor control 1.5KW,which makes much more tidy.

3.Automatic collect bags and finish stack bags with double fold device.

1.This device special for this high speed model.

2.When roll film feeding so fast that the film will move little left and right, with this EPC device to be control the film feeding corrected to the right position.

3.This EPC system will enhance the productivity of machine.

4.One set EPC system to control two lines.

1.Sealing knife "turnover" device ,which easy to clean the knife ,which is better to keep the maintenance easy.

2.The whole set of bags has design of swaying ,no paste between two bags mouth.