- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HONGXING

-

Dimension(L*W*H):

-

Varies

-

Weight:

-

20000 KG

-

Marketing Type:

-

Hot Product

Quick Details

-

Application:

-

rocks or ores, rocks or ores

-

Capacity(t/h):

-

90-524

-

Place of Origin:

-

HEN

-

Brand Name:

-

HONGXING

-

Dimension(L*W*H):

-

Varies

-

Weight:

-

20000 KG

-

Marketing Type:

-

Hot Product

Product Description

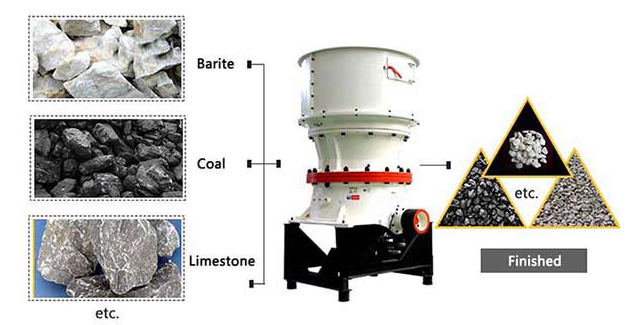

Product Application

1. Single-cylinder cone crusher is a highly efficient crusher designed by our company on the basis of introducing American

technology and combing with the performance of the metal materials in China to satisfy the needs of developing countries.

2. The external form of this crusher is very concise and compact because the unique design structure of the bottom cylinder

completes three important functions of directly adjusting the discharging mouth, preventing iron from going through the crushing

chamber and cleaning the chamber.

3. Single-cylinder cone crusher is divided into standard type and short-headed type which are used for medium crushing and fine

crushing respectively.

4. It is suitable for crushing all kinds of ores and rocks with high and over-medium hardness in medium, construction, water and

electricity, transportation, chemistry and building material industry.

1. Single-cylinder cone crusher is a highly efficient crusher designed by our company on the basis of introducing American

technology and combing with the performance of the metal materials in China to satisfy the needs of developing countries.

2. The external form of this crusher is very concise and compact because the unique design structure of the bottom cylinder

completes three important functions of directly adjusting the discharging mouth, preventing iron from going through the crushing

chamber and cleaning the chamber.

3. Single-cylinder cone crusher is divided into standard type and short-headed type which are used for medium crushing and fine

crushing respectively.

4. It is suitable for crushing all kinds of ores and rocks with high and over-medium hardness in medium, construction, water and

electricity, transportation, chemistry and building material industry.

Advantage

Constant crushing chamber type

In the whole lining wear life cycle, the discharge particle size and productivity remain basically unchanged.

Positive pressure dustproofsystem

Effectively prevent dust and other sundries from entering the equipment and oil tank to avoid lubricating oil pollution.

No glue packing lining plate installation, easy replacement

No glue packing structure can reduce the replacement time of lining board, save the replacement cost Improve equipment uptime.

Intelligent control system

The human-machine interaction interface is easy to understand, easy to use and efficient, making the operation and maintenance

simple, maximize productivity.

simple, maximize productivity.

Working Principle

Cone Crusher working principle

When single-cylinder hydraulic cone crusher works, the electro motor drives the pinion of the crusher, the pinion drives the rack

wheel, the rack wheel assembly including rack wheel, rack wheel brace and eccentric steel bushing drives the eccentric bushing

assembly including eccentric cylinder liner and eccentric copper bushing and the spindle unit including principal axis, inner cone

and inner cone lining plate to revolves around the theoretical perpendicular line inside the copper bushing and the spindle unit

can realize rotation around the central line of the principal axis inside the eccentric copper bushing.

When single-cylinder hydraulic cone crusher works, the electro motor drives the pinion of the crusher, the pinion drives the rack

wheel, the rack wheel assembly including rack wheel, rack wheel brace and eccentric steel bushing drives the eccentric bushing

assembly including eccentric cylinder liner and eccentric copper bushing and the spindle unit including principal axis, inner cone

and inner cone lining plate to revolves around the theoretical perpendicular line inside the copper bushing and the spindle unit

can realize rotation around the central line of the principal axis inside the eccentric copper bushing.

Specifications

|

Model

|

cavities

|

Maximum Feeding Size(mm)

|

Minimum Discharging Size(mm)

|

install Power(kw)

|

capacity(t/h)

|

|

SC(S)100

|

C1

|

250

|

22

|

90

|

85-170

|

|

|

C2

|

200

|

19

|

90

|

70-130

|

|

SC(S)160

|

C1

|

360

|

25

|

160

|

125-345

|

|

|

C2

|

300

|

22

|

160

|

108-305

|

|

SC(S)250

|

C1

|

450

|

35

|

250

|

267-605

|

|

|

C2

|

400

|

29

|

250

|

225-515

|

|

SC(S)315

|

C1

|

560

|

41

|

315

|

349-1050

|

|

|

C2

|

500

|

38

|

315

|

318-892

|

Machine Details

Packing & Delivery

|

Packaging

|

|

|

|

Size

|

3180*2720*2620MM

|

|

|

Weight

|

20t

|

|

|

Packaging Details |

1.The motor will be packed in wooden case. 2.If export to european countries,the wooden box will be fumigated.If container is too

tigher,we will use pe film for packing or pack it according to customers special request. |

|

|

Packaging

|

|

|

|

Size

|

2680*2160*2800

|

|

|

Weight

|

23t

|

|

|

Packaging Details |

1.The motor will be packed in wooden case. 2.If export to european countries,the wooden box will be fumigated.If container is too

tigher,we will use pe film for packing or pack it according to customers special request. 3. It will be separated to put into one container. |

|

Hot Searches