- Product Details

- {{item.text}}

Quick Details

-

MF:

-

SiO2

-

EINECS No.:

-

231-545-4

-

Place of Origin:

-

Germany

-

Appearance:

-

white powder, Nano-powder

-

Application:

-

rheology and thixotropy control, Rubber/sealant/Paint/coating/defoaming agents/ink

-

Brand Name:

-

king

-

Model Number:

-

HT-903

-

Feature:

-

high performance

-

Specific surface area:

-

190+20 m2/g

-

PH(4% dispersions):

-

3.8-5.0

-

Carbon content:

-

0.8-1.4 Wt.%

-

Loss on drying:

-

≤0.5 Wt.%

-

Bulk density:

-

40-50 g/l

-

SiO2 content:

-

≥99.8 Wt.%

-

MOQ:

-

500kg

Quick Details

-

CAS No.:

-

112945-52-5

-

Purity:

-

SiO2 content 99.8%min

-

Other Names:

-

fumed silica

-

MF:

-

SiO2

-

EINECS No.:

-

231-545-4

-

Place of Origin:

-

Germany

-

Appearance:

-

white powder, Nano-powder

-

Application:

-

rheology and thixotropy control, Rubber/sealant/Paint/coating/defoaming agents/ink

-

Brand Name:

-

king

-

Model Number:

-

HT-903

-

Feature:

-

high performance

-

Specific surface area:

-

190+20 m2/g

-

PH(4% dispersions):

-

3.8-5.0

-

Carbon content:

-

0.8-1.4 Wt.%

-

Loss on drying:

-

≤0.5 Wt.%

-

Bulk density:

-

40-50 g/l

-

SiO2 content:

-

≥99.8 Wt.%

-

MOQ:

-

500kg

Product Description

hydrophobic fumed silica HT-903 (The performance of HT-903 can substitute straight for DM20S.

HT-903 SiO2 is a hydrophobic silicon dioxide by gas phase method modified by Dimethyl Dichlorosilane (DDS) based on hydrophilic silicon dioxide with a specific surface area of 200 M2/G. It is a kind of high-purity Nano-powder

HT-903 is a hydrophobic silicon dioxide by gas phase method modified by Dimethyl Dichlorosilane (DDS) based on hydrophilic silicon dioxide with a specific surface area of 200 M2/G. It is a kind of high-purity Nano-powder.

HT-903 is a hydrophobic silicon dioxide by gas phase method modified by Dimethyl Dichlorosilane (DDS) based on hydrophilic silicon dioxide with a specific surface area of 200 M2/G. It is a kind of high-purity Nano-powder.

Product Picture

|

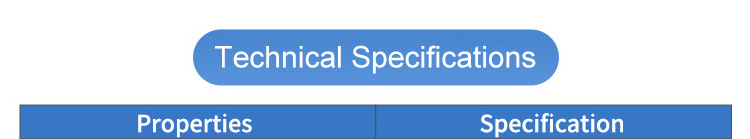

Characteristics

|

Unit

|

190+20

|

|

Specific surface area

|

m2/g

|

190+20

|

|

PH(4% dispersions)

|

|

3.8-5.0

|

|

Carbon content

|

Wt.%

|

0.8-1.4

|

|

Loss on drying(for 2h at 105℃)

|

Wt.%

|

≤0.5

|

|

Loss on heating(Heating for 2h at 1000℃,based on the article after drying for 2h at 105 ℃)

|

Wt.%

|

≤2.0

|

|

Bulk density

|

g/l

|

40-50

|

|

SiO2 content (based on the article after heating)

|

Wt.%

|

≥99.8

|

Application

Organo-silicon rubber, organo-silicon sealant, coating, ink, paint, resin, printer Toner, powder coatings.

Hot Searches