- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Name:

-

mold

-

Raw material:

-

steel

-

Certification:

-

ISO9001

-

Feature:

-

Fast Construction

-

Commom use:

-

Choose One Profile)

-

Tile Type:

-

Steel Coil

-

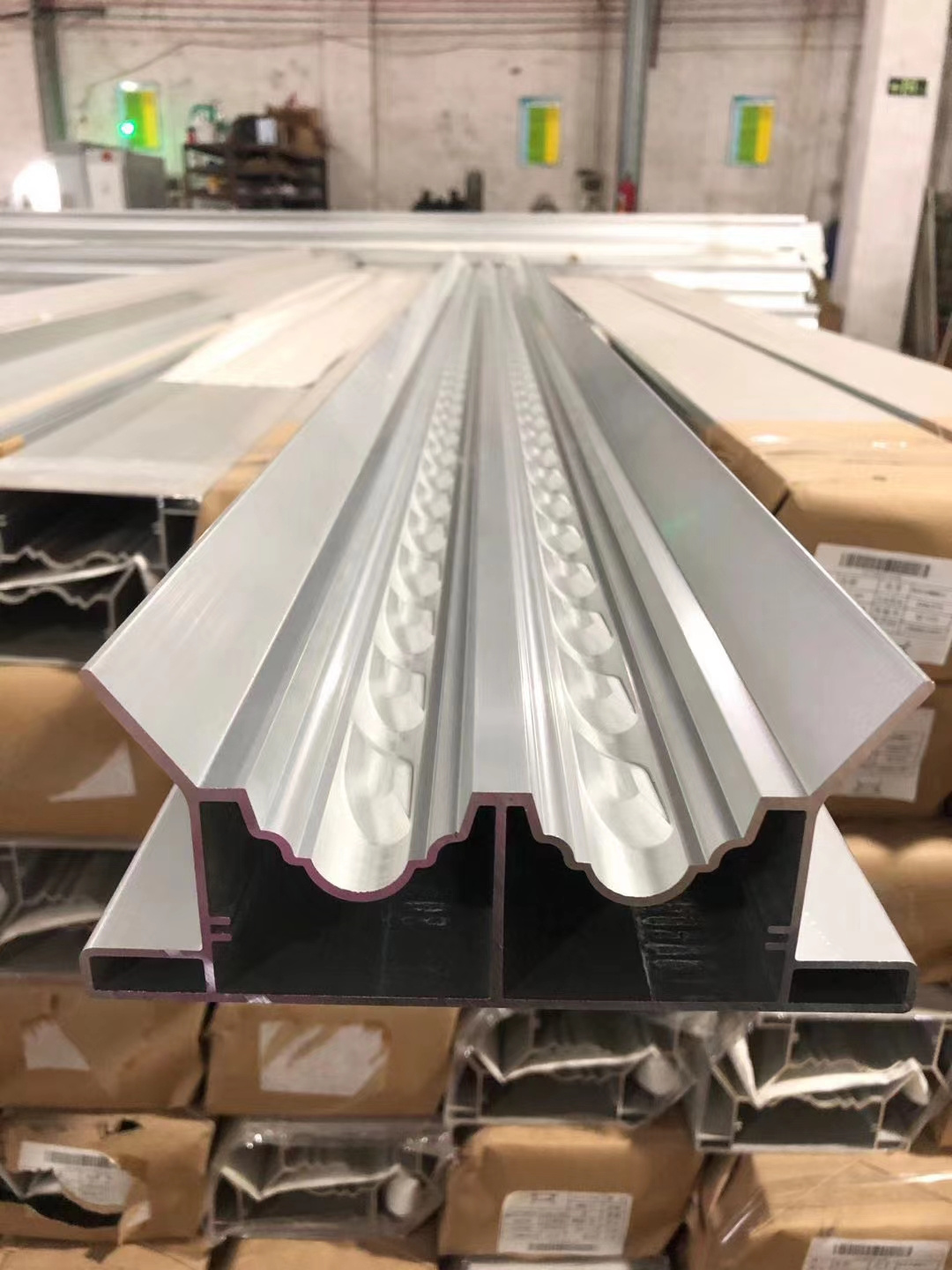

mould cornice Width:

-

90MM 110MM 130MM 1500MM

-

Pattern:

-

100% clear

-

Function:

-

Makeing Gypsum Moulding

Quick Details

-

After-sale Service:

-

Online technical support, Onsite Installation, Onsite Training, Onsite Inspection, Free spare parts, Return and Replacement

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation, NONE

-

Application:

-

Hotel, Villa, Apartment, Office Building, Hospital, School, Mall, Sports Venues, Leisure Facilities, Supermarket, Warehouse, Workshop, Farmhouse, Courtyard

-

Place of Origin:

-

China

-

Name:

-

mold

-

Raw material:

-

steel

-

Certification:

-

ISO9001

-

Feature:

-

Fast Construction

-

Commom use:

-

Choose One Profile)

-

Tile Type:

-

Steel Coil

-

mould cornice Width:

-

90MM 110MM 130MM 1500MM

-

Pattern:

-

100% clear

-

Function:

-

Makeing Gypsum Moulding

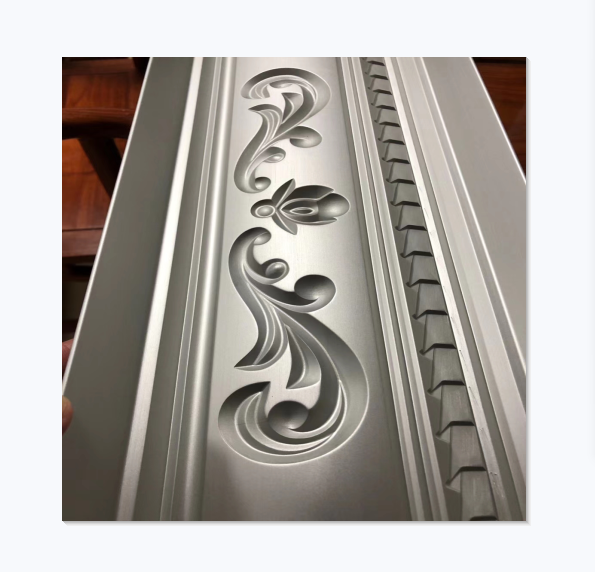

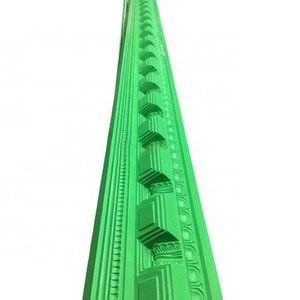

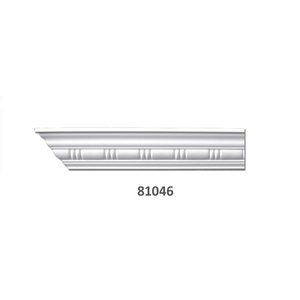

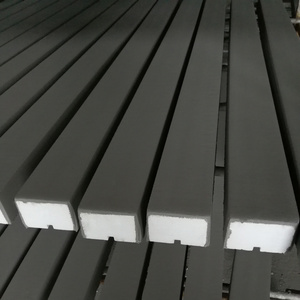

2020 high quality aluminum cornice moulding to make gypsum cornice for sale

Gypsum cornice is a kind of building decoration material for house, maily for indoor ceiling. It can be with various decorative design,which is artistic with cheap price. Except the function of fire-proof, moisture-proof,sound-proof and heat-isolated, gypsum cornice can reach luxurious decoration effect.

|

Machine Name |

Automatic Gypsum Cornices Making Machine |

|

WEIGHT |

12 tons |

|

Speed |

20-25 m/min |

|

Drive |

Belt transmission ,chain and mechanical telex |

|

Perimeter |

73.6M to 128M |

|

Type |

Automatic |

|

Customized |

Yes |

|

Installed capacity |

30 KW |

|

Excitation Frequency |

2800 /min |

|

Production capacity |

1500pcs-6000pcs per day |

|

SKU |

XTJ-2460 |

|

SIZE |

Length : 30 m -60m Width :3.8 meter |

|

Container |

1*40HQ , 68 CBM Size : 12m*2.35m*2.69m |

|

Machinery Color |

White & Red |

|

Molding cycle |

10min |

1. Mature technology. We are professional gypsum equipment manufacturer. The automatic gypsum line production equipment inherits from mature technology, experience of paper faced gypsum board production line.

2. Good quality. Because of professional gypsum slurry treatment technology, there is no bubble in the process of production and has character of high strength ,large density. Ordinary gypsum powder can achieve good effect as well as high strength gypsum powder dose .

3. High degree of automation. Only 3-6 workers needed .

4. Made from premium materials. The design, texture, thickness of material meet the national standards. The main frame deformation could be used for 13 years. Accessories selection criteria is that the key components used imported brand meanwhile other fittings choose domestic big brand .

5. A strong sense of security, after-sales service we have s professional team.

Packing :exported standard carton packing

Delivery :7-15 days after the order confirmed

The company always adhere to the "innovation, quality, service, Thanksgiving" concept of development. Independent innovation unceasingly, the strict with product quality, a full range of tracking services to our clients and insist to do high quality products. Quality is the life of enterprise .After more than 10 years of continuous efforts to continue to grow and developing , the current staff of 300 people.Now the company has a group of lean management, and high-quality professional and technical team, including 2 male, Dr. Engineers for four engineers in the undergraduate course.Elega nt and comfortable office environment,and have built a 20000 square meters of new standardized plant.

Main Products :

The factory professional produce automatic PVC gypsum ceiling making machine ,the automatic gypsum cornice making machine automatic punching machine ,and all kinds of packing machine and hot shrinking machine,”LUOTAIDINA” PVC gypsum ceiling ,various gypsum cornice ,gypsum cornice molds .The PVC gypsum ceiling we produce has the quality of the .fireproof, moisture-proof, dust-proof, insulative, easy installation, artistic appearance, high quality and environmental friendly, fashion etc., widely used in commercial buildings, hotels, hospitals, factories, shopping centers, and other senior public buildings and home decoration.Have signed the supply agreement with the world famous brand "Armstrong" , and exported to the America and Britain market etc.

The factory independent research and develop a of new high quality automatic gypsum cornice making machine .Adopting PLC numerical control computer operation,it could achieve automatically feeding, automatic grouting, automatic lapping, automatic glass fiber line laying, automatic flattening, automatic mold cleaning , automatic release agent spraying, automatic output speed controlling.The whole mechanical equipment with high performance, low energy consumption, easy to operate features.The gypsum cornice it produce, compact patterns, with green, fire beautiful, high quality and other advantages.At the meantime, for the sixty meters standard machine ,the daily output could reach 8000 pieces one day,which can significantly reduce production costs .The equipment can be customized according to customer site and production needs.to help the customers to occupy the market .

Linyi Zhouxing Building Materials co., LTD will hold thoughtful and considerate, good at serving customers ’ development concept. with professional technical innovation, from customers ’ system configuration consultation to equipment installation, debugging and after-sales maintenance and so on, we will provide the high quality service in the whole processes. In the future road of development, we will continue to keep leading position in the industry, strive to produce excellence products, pursuit perfect, and reward our customers with high quality service. Linyi Zhouxing Building Materials co., LTD will wholeheartedly join hands with the vast number of old and new customers to create brilliant!

1.Q: Are you factory or trading company?

A: We are a factory and manufacturer in Linyi city Shandong China

2. Q: Do you make test before shipment?

A: we always test machine run perfectly fully Before shipment

3. Q: Can you guarantee your quality?

A: Of course. We are the professional manufacture factory. Professional design team and QC online to check each part. Best quality is our principle all the time.

4.Q: How do you make your price?

A: We make the price according to our comprehensive costing. And our price will lower than the trade company because we are manufacture.

5. Q:Service and Payment Terms?

A. We usually accept T/T, L/C;

B. T/T: 30% in advance as down payment, the balance before delivery;

C. We take pictures of finished products before delivery.