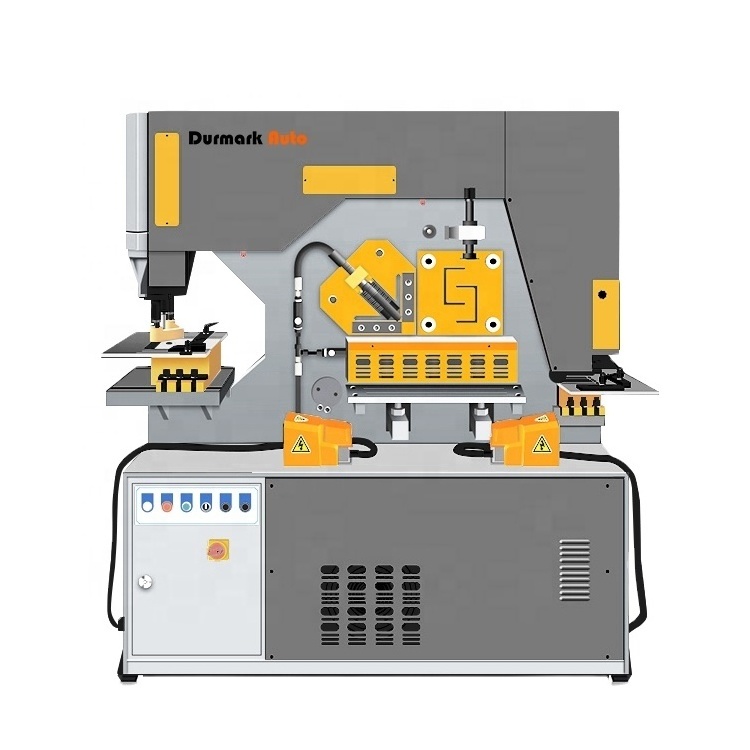

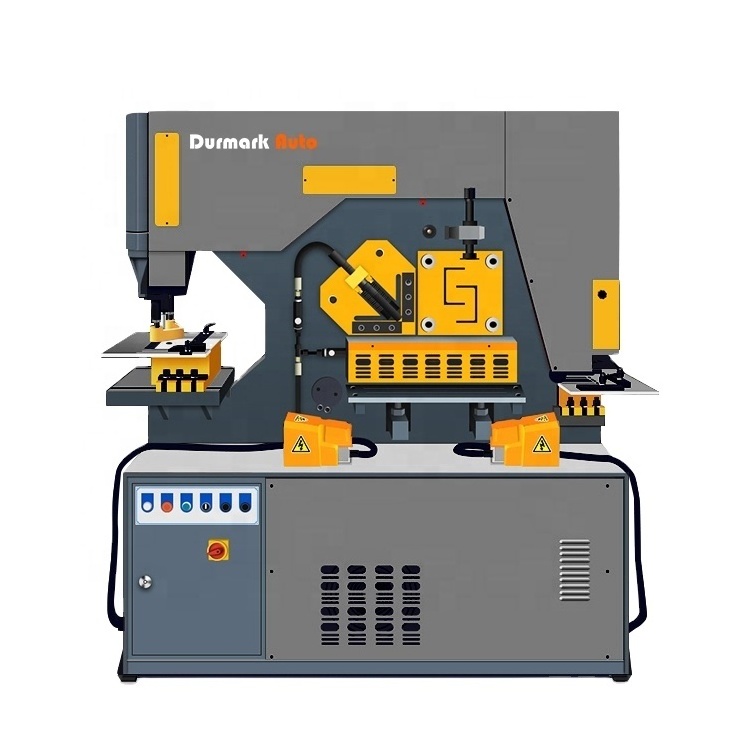

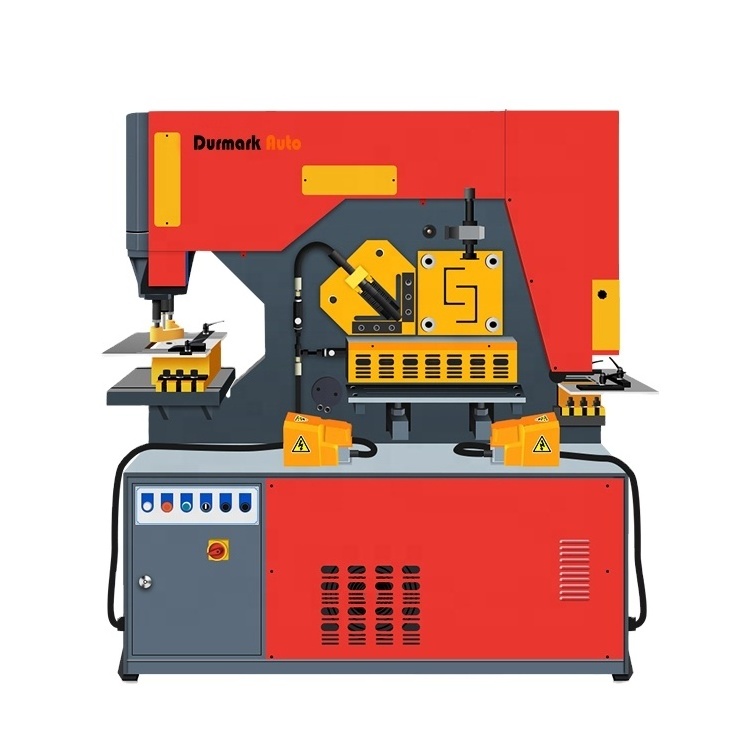

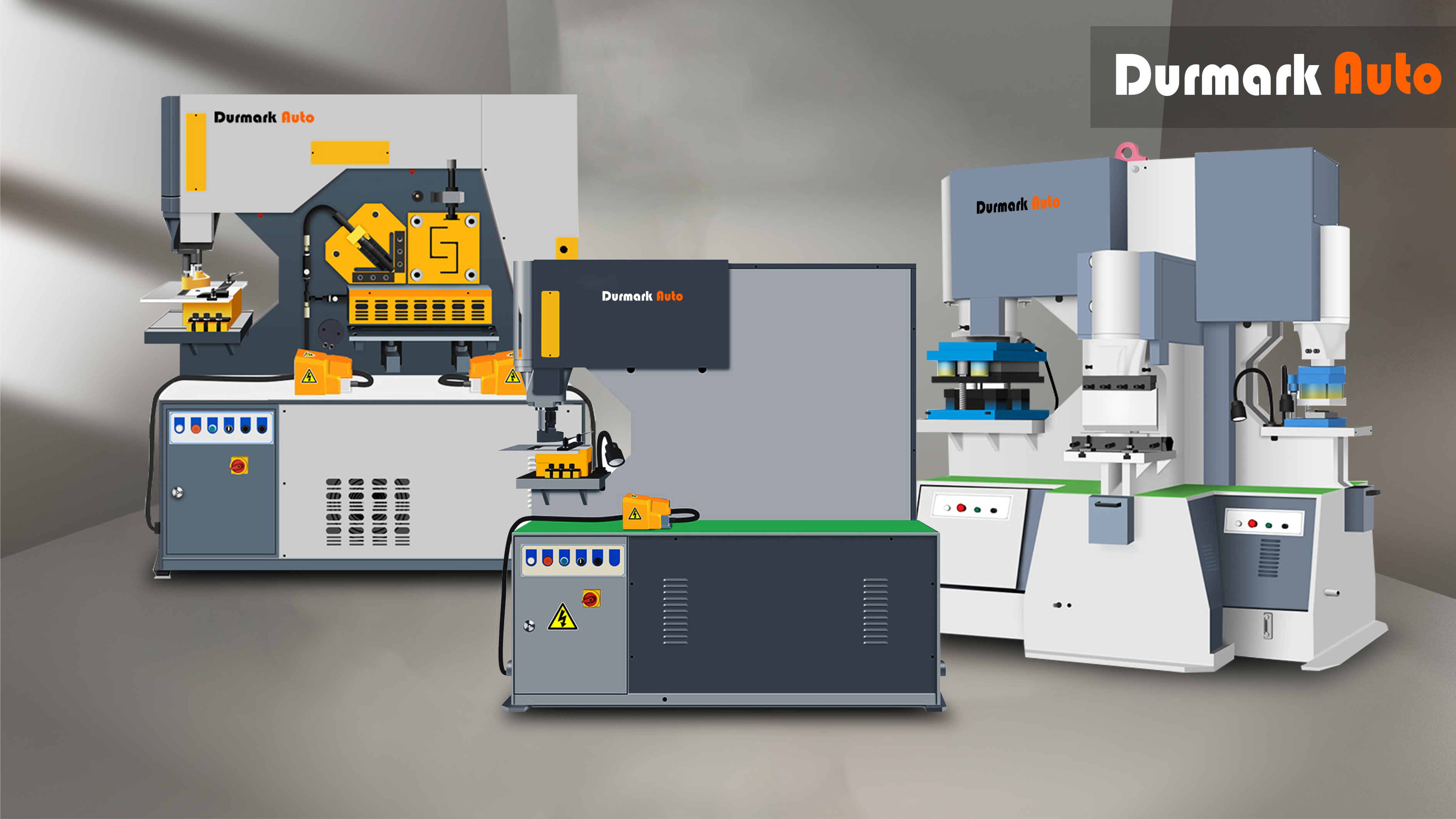

hydraulic Ironworker is a combination of functions in one sheet metal and profile processing equipment. Hydraulic combined punching and shearing machine is widely used in steel structure processing, storage shelves, high voltage wire tower, telecom tower, street lamp, advertising signs, elevator, ventilation pipe and other civil facilities production enterprises.

1. Adopt hydraulic transmission, the whole machine has reasonable structure, light weight, low noise, light and reliable and overload performance.

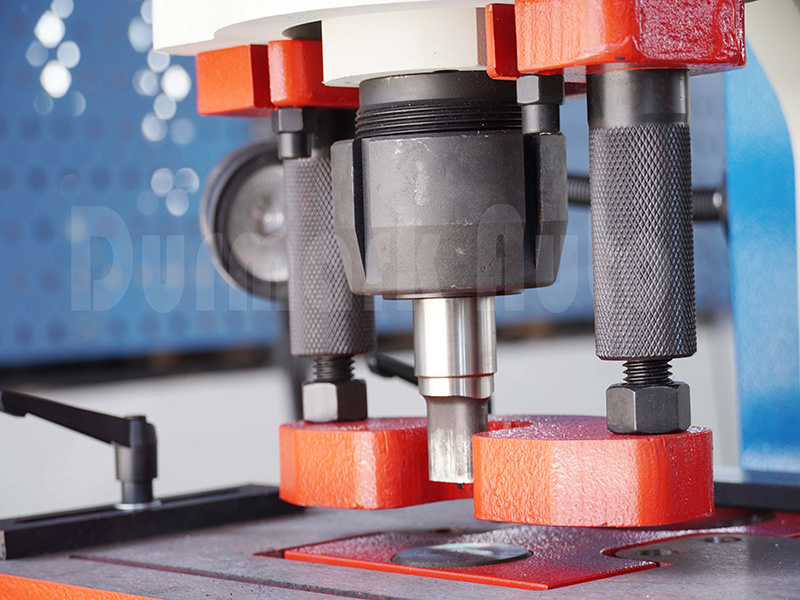

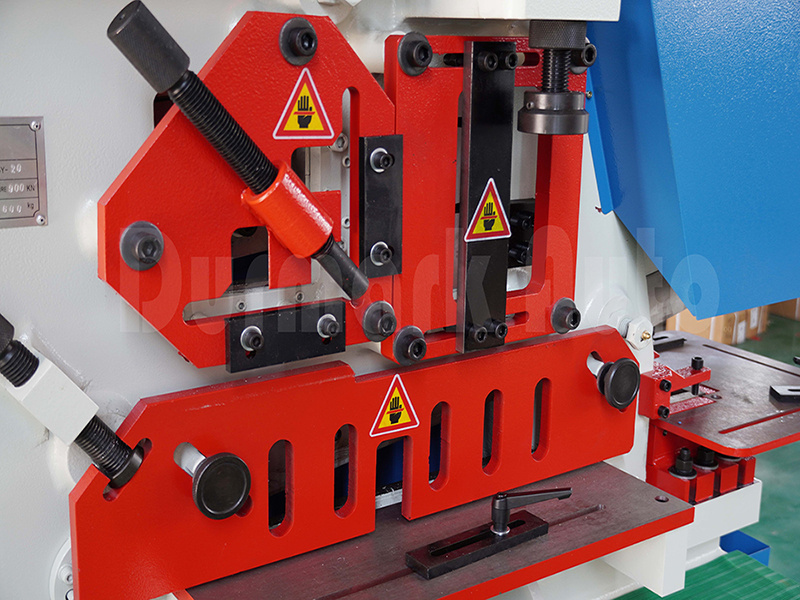

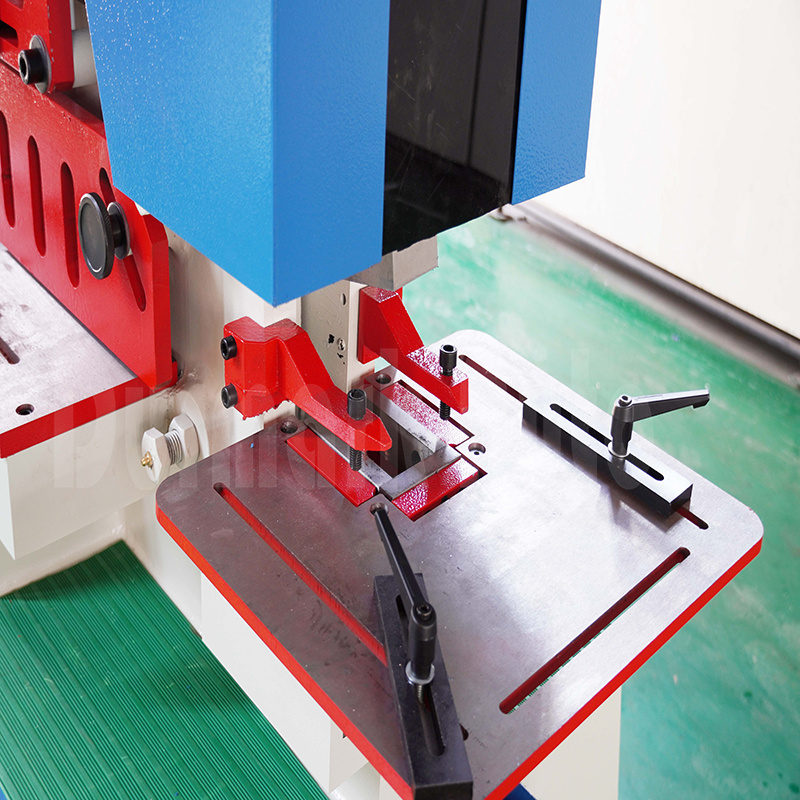

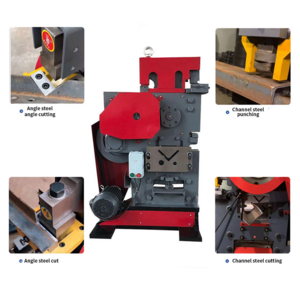

2. The machine is equipped with punching station, channel steel and Angle steel shearing station, thick plate shearing station, round steel and square steel cutting station, Angle cutting station. Large punching, plate bending, channel steel punching, shutter and pipe Angle cutting accessories are available.

3. Standard equipped with five stations and double hydraulic workstations. Can work independently at the same time. The machine does not need any level debugging, placed in place can be used. CNC control system is optional to increase automatic punching and cutting efficiency.

4. The machine adopts Europe's top processing technology, the frame is welded by the whole machine, after high temperature quenching treatment, so that the frame has high steel, high strength; The cutting tool is treated with special vacuum high temperature to prolong its service life.

5. With the pipe cutting mold can also cut off the pipe and open the groove, high efficiency, cost saving, cutting section beautiful