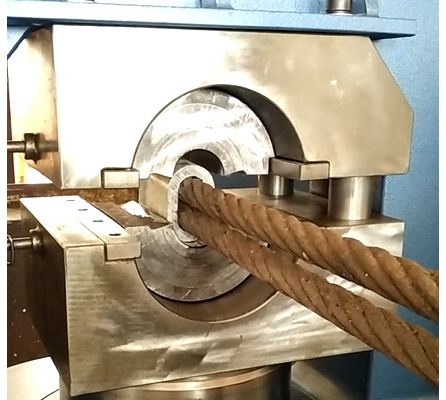

Fill hydraulic oil and connect wires. Stamp pedal switch to test the machine up and down. Install the dies. Adjust the pressure

according to the diameter of wire ropes. Put sleeves on wire ropes and press the wire ropes by stamping pedal switch. Put our the

finished slings out.

- Product Details

- {{item.text}}

Quick Details

-

Keyword:

-

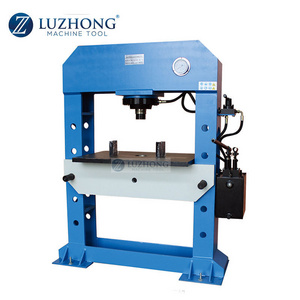

Hydryalic Press Machine

-

Work pressure:

-

56Mpa or adjustable

-

Press range:

-

upto 34mm

-

Colour:

-

blue,as customers' request

-

Structure:

-

Integrative structure

-

Function:

-

Forming

-

Brand:

-

XINGTAI

-

Advantage:

-

Easy Operation Machine

-

Power souce:

-

Hydraulic Power

Quick Details

-

Machine Type:

-

Double Column Hydraulic Press

-

Place of Origin:

-

Jiangsu, China

-

Product name:

-

GT-350T Hydraulic Press Machine

-

Keyword:

-

Hydryalic Press Machine

-

Work pressure:

-

56Mpa or adjustable

-

Press range:

-

upto 34mm

-

Colour:

-

blue,as customers' request

-

Structure:

-

Integrative structure

-

Function:

-

Forming

-

Brand:

-

XINGTAI

-

Advantage:

-

Easy Operation Machine

-

Power souce:

-

Hydraulic Power

Hot Product

Product Description

Xingtai hydraulic wire rope press machines are used to make pressed wire rope sling. The body of swagers are manufactured from one single block construction that ensure strength, long service life and a minimum of maintenance. All swagers are thoroughly test run and are supplied with a full tank of oil.

|

Mode No.

|

GT-350

|

|

Max press power (KN)

|

3500

|

|

Max wire rope diameter in one pressing (mm)

|

30

|

|

Max wire rope diameter in multi-pressing (mm)

|

36

|

|

3Power (KW)

|

1.5

|

|

Max working pressure (Mpa)

|

56

|

|

Max piston movement (mm)

|

80

|

|

The up speed of piston (mm/sec)

|

8

|

|

The down speed of piston (mm/sec)

|

10

|

|

Total length (mm)

|

1200

|

|

Total width (mm)

|

600

|

|

Total height (mm)

|

1400

|

|

Net weight (kg)

|

1000

|

Direction for use

Description of application effect

Packing&Shipping

Shrinkwrap and iron box, dies are packed in iron box

Company Introduction

Jiangsu Xingtai Hydraulic Manufacture Co.,Ltd was founded in 1992, and located in Taizhou City, Jiangsu Province, China. Xingtai hydraulic engages in hydraulic wire rope press machine, wire rope annealing and tapering machine,aluminium sleeve,and lifting clamp. Xingtai hydraulic owns advanced producing equipment, tremendous technique capacity, authoritative test facility, prefect quality management system.

Xingtai hydraulic swage construction is forgged from high stength alloy steel. The body of swagers are manufactured from one single block construction that ensure strength and long service life. Xingtai hydraulic machines adopt high pressure and low pressure pump oil supply system to bring in fast upward and downward speed as well as smooth pressing process, greatly improving the pressing quality and production efficiency. Xingtai hydraulic machines have exported to UK, Australia, Holland, Latvia, Malaysia, Thailand, India, Russia, Botswana,Polland and so on.

Xingtai hydraulic regards the concept of high quality, competitive price, eternal promise as service policy, We shall meet

customers'need and offer customer best service. We will try our best to provide service to our old and new clients as before and build our nice future together.

Xingtai hydraulic swage construction is forgged from high stength alloy steel. The body of swagers are manufactured from one single block construction that ensure strength and long service life. Xingtai hydraulic machines adopt high pressure and low pressure pump oil supply system to bring in fast upward and downward speed as well as smooth pressing process, greatly improving the pressing quality and production efficiency. Xingtai hydraulic machines have exported to UK, Australia, Holland, Latvia, Malaysia, Thailand, India, Russia, Botswana,Polland and so on.

Xingtai hydraulic regards the concept of high quality, competitive price, eternal promise as service policy, We shall meet

customers'need and offer customer best service. We will try our best to provide service to our old and new clients as before and build our nice future together.

FAQ

Q: Are you trading company or factory?

A: We are professional wire rope pressing machine and wire rope annealing machines manufacturer with 20 years' experience.

Q: What is after-sales services?

A: 24 hours around the clock & 12 months warranty

Life-long maintenance service for the product

Q: If I didn't use press machine before, how can I install and operate the machine?

A: 1. Fix fitted mould, tight the bolts on the left of both tool set ( the tool is offered by factory);

Refer diameter of wire rope table to adjust pressure, put sleeve with steel wire rope in the middle of mould Vertically.

2. Operate pedal rise switch, the piston will rise and the rising pilot lamp lights; Auto-stop when

reach given pressure and finish pressing;

3.Operate descendent switch, the piston will descend and the descendent pilot lamp lights; and take out pressedsteel wire rope.

We will delivery machine with use manual and CD.

Q: Shall I see the machine work before I order?

a. Please send us inquiry and we will check whether there are customers in your country.

b. You may come our factory, we will teach you how to operate.

c. We may send you video.

Q: How long to finish one machine if I place order?

A: As usually, delivery time is 30 days. If we have machine and dies that you need in stock, we may delivery machine in 7-10 days

after receipt of your payment.

Q: How can we believe your quality or service?

A: We have many oversea customers, you can contact them to know more about us. Maybe we have customers in your country, you may

call them or visit them to see our machine.

If you have any other question please do feel free to contact us.

A: We are professional wire rope pressing machine and wire rope annealing machines manufacturer with 20 years' experience.

Q: What is after-sales services?

A: 24 hours around the clock & 12 months warranty

Life-long maintenance service for the product

Q: If I didn't use press machine before, how can I install and operate the machine?

A: 1. Fix fitted mould, tight the bolts on the left of both tool set ( the tool is offered by factory);

Refer diameter of wire rope table to adjust pressure, put sleeve with steel wire rope in the middle of mould Vertically.

2. Operate pedal rise switch, the piston will rise and the rising pilot lamp lights; Auto-stop when

reach given pressure and finish pressing;

3.Operate descendent switch, the piston will descend and the descendent pilot lamp lights; and take out pressedsteel wire rope.

We will delivery machine with use manual and CD.

Q: Shall I see the machine work before I order?

a. Please send us inquiry and we will check whether there are customers in your country.

b. You may come our factory, we will teach you how to operate.

c. We may send you video.

Q: How long to finish one machine if I place order?

A: As usually, delivery time is 30 days. If we have machine and dies that you need in stock, we may delivery machine in 7-10 days

after receipt of your payment.

Q: How can we believe your quality or service?

A: We have many oversea customers, you can contact them to know more about us. Maybe we have customers in your country, you may

call them or visit them to see our machine.

If you have any other question please do feel free to contact us.

Hot Searches