- Product Details

- {{item.text}}

Quick Details

-

Spindle Bore(mm):

-

450

-

Width of bed (mm):

-

35 mm

-

Spindle Motor Power(kW):

-

7.5

-

Travel (X Axis)(mm):

-

300 mm

-

Travel (Z Axis)(mm):

-

400 mm

-

Place of Origin:

-

Hebei China

-

Dimension(L*W*H):

-

2350*1700*1950

-

Model Number:

-

FCK46

-

Weight (KG):

-

2600

-

Marketing Type:

-

New Product 2024

-

Color:

-

Customised

-

Keyword:

-

Automatic CNC Lathe Machine

Quick Details

-

Type:

-

Horizontal

-

Max. Length of Workpiece (mm):

-

400

-

Max. Spindle Speed (r.p.m):

-

4000 r.p.m

-

Spindle Bore(mm):

-

450

-

Width of bed (mm):

-

35 mm

-

Spindle Motor Power(kW):

-

7.5

-

Travel (X Axis)(mm):

-

300 mm

-

Travel (Z Axis)(mm):

-

400 mm

-

Place of Origin:

-

Hebei China

-

Dimension(L*W*H):

-

2350*1700*1950

-

Model Number:

-

FCK46

-

Weight (KG):

-

2600

-

Marketing Type:

-

New Product 2024

-

Color:

-

Customised

-

Keyword:

-

Automatic CNC Lathe Machine

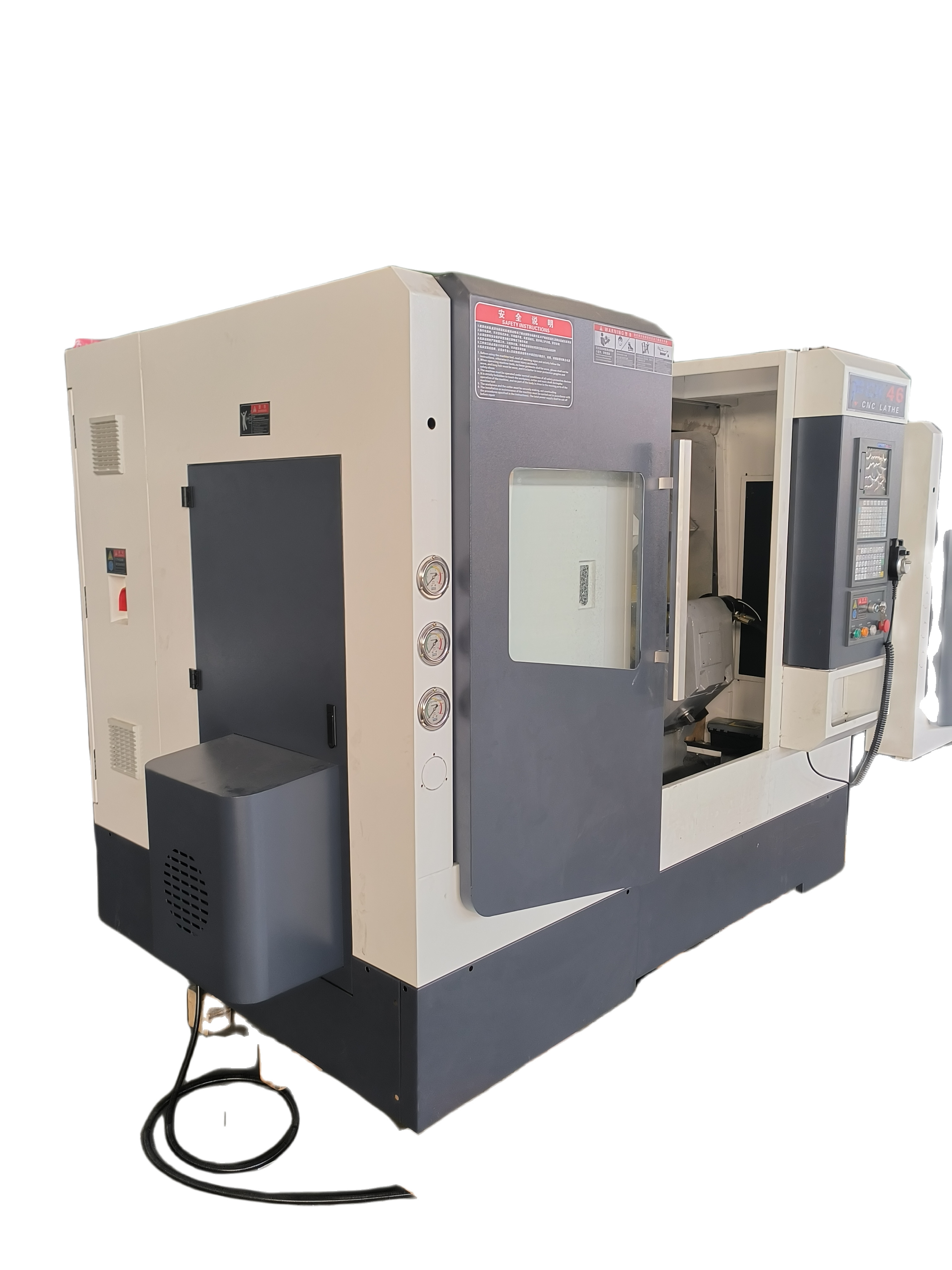

The machine tool bed body adopts the whole casting, strong earthquake resistance, the machine tool deformation is less, the bed body tilt 45, the large drag plate and the knife rack inclined, make the operation and discharge of the machine tool become very convenient. The appearance of the machine tool is beautiful, and the space is less.

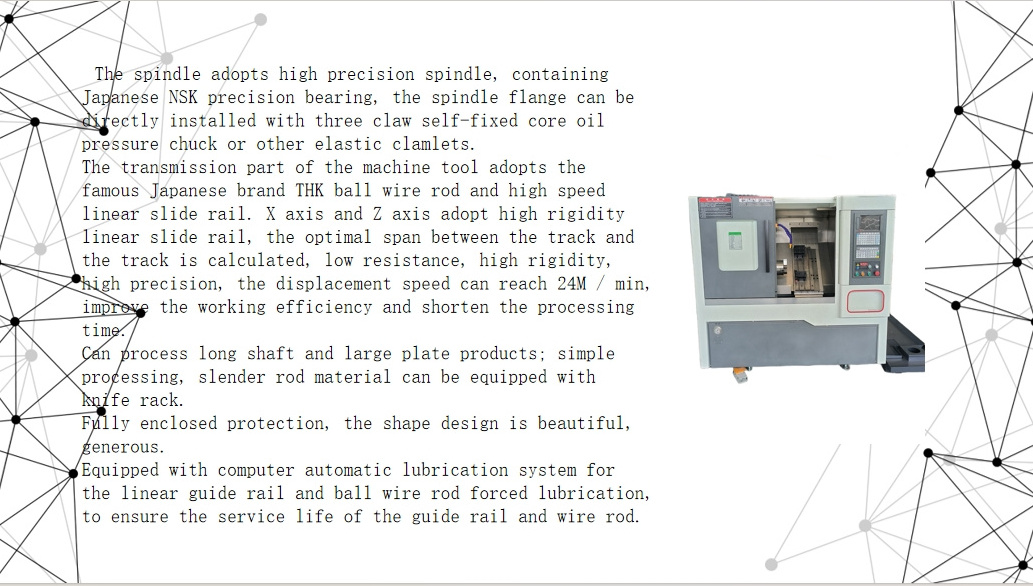

The spindle adopts high precision spindle, containing Japanese NSK precision bearing, the spindle flange can be directly installed with three claw self-fixed core oil pressure chuck or other elastic clamlets.

The transmission part of the machine tool adopts the famous Japanese brand THK ball wire rod and high speed linear slide rail. X axis and Z axis adopt high rigidity linear slide rail, the optimal span between the track and the track is calculated, low resistance, high rigidity, high precision, the displacement speed can reach 24M / min, improve the working efficiency and shorten the processing time.

Can process long shaft and large plate products; simple processing, slender rod material can be equipped with knife rack.

Fully enclosed protection, the shape design is beautiful, generous.

Equipped with computer automatic lubrication system for the linear guide rail and ball wire rod forced lubrication, to ensure the service life of the guide rail and wire rod.

|

position |

project |

FCK46 |

|

range of work |

Maximum swing diameter on the bed( mm ) |

450 |

|

Maximum swing diameter on the knife holder (mm) |

160 |

|

|

Maximum cut diameter( mm ) |

450 |

|

|

Maximum cutting length( mm ) |

400 |

|

|

Travel and feed |

X axis itinerary( mm ) |

300 |

|

Z axis itinerary( mm ) |

4 00 |

|

|

X axis movement speed( mm/min ) |

18 000 |

|

|

Z axis movement speed( mm/min ) |

18 000 |

|

|

hand wheel( mm ) |

0.001/0.01/0.1 |

|

|

X, Z feed rate( mm/min ) |

0~5000 |

|

|

X and Z manual feed speed( mm/min ) |

0~1260 |

|

|

positional accuracy |

The X-axis has a repeated positioning accuracy( mm ) |

0.005 |

|

X axis positioning accuracy( mm ) |

0.008 |

|

|

Z-axis repeat positioning accuracy( mm ) |

0.005 |

|

|

Z axis positioning accuracy( mm ) |

0.01 |

|

|

main arbr |

Spindle rotation speed (rpm) |

4000 |

|

Spindle nose end |

A2-6 |

|

|

Main shaft through aperture (mm) |

53 |

|

|

The clamping way |

A 10-inch hydraulic chuck |

|

|

Through hole diameter of hydraulic chper |

42mm |

|

|

DOTA |

Number of knife seats |

12 station hydraulic servo knife tower |

|

Change the knife time( s ) |

0.25 |

|

|

Tool installation size( mm ) |

2 0 ×2 0 |

|

|

Installation diameter of the boring cutter holder( mm ) |

25 32 |

|

|

Tail seat |

Tail seat trip( mm ) |

35 0 |

|

Tail seat core shaft diameter( mm ) |

50 |

|

|

Top cone |

MT -4 |

|

|

Tail seat core shaft itinerary( mm ) |

100 |

|

|

main motor |

Servo main motor power (kw) |

7.5 |

|

X, Z axis

|

X-axis gauge and slider specifications |

32 |

|

Z-axis gauge and slider specifications |

32 |

|

|

Z axis lead screw |

32*10 |

|

|

X axis lead screw |

40*10 |

|

|

coolant system |

Coolant Capacity (L) |

1 00 |

|

Motor type( 1HP )( kw ) |

0.18 |

|

|

lead rail |

|

Line rail |

|

lathe bed |

|

Overall type 30-degree inclined bed body |

|

size |

Installation (length * width * height)( mm ) |

2350*1 70 0* 195 0 |

|

weight |

Mechanical weight( kg ) |

26 00 |