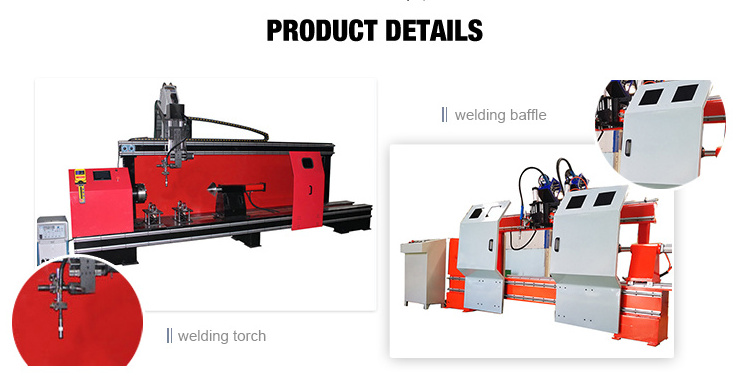

- Product Details

- {{item.text}}

Quick Details

-

Welding Mode:

-

TIG MIG MAG SAW PAW

-

Welding Diameter:

-

50-800mm

-

Dimensions:

-

Customized

-

Use:

-

Customized

-

Voltage:

-

380V 50Hz / 220V 60Hz

-

Weight (KG):

-

1900 KG

-

Product name:

-

China stainless steel MIG TIG ARC circular seam welding machine

-

Welding Material:

-

carbon steel; stainless steel;galvanized steel

-

Control mode::

-

PLC Control

-

Customised::

-

available

-

Working mode::

-

Auto circular seam welder with PLC control

-

Application::

-

solar water heater tank, enamessel tank, LPG/LNG cylinder etc

-

Width and thickness:

-

Customized

-

Features:

-

High efficiency, high precision,Roundness is accurate

-

Function::

-

steel tank welding

-

Weight:

-

Customized

Quick Details

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

MC

-

Forming Time:

-

1s-10s Adjustable

-

Welding Mode:

-

TIG MIG MAG SAW PAW

-

Welding Diameter:

-

50-800mm

-

Dimensions:

-

Customized

-

Use:

-

Customized

-

Voltage:

-

380V 50Hz / 220V 60Hz

-

Weight (KG):

-

1900 KG

-

Product name:

-

China stainless steel MIG TIG ARC circular seam welding machine

-

Welding Material:

-

carbon steel; stainless steel;galvanized steel

-

Control mode::

-

PLC Control

-

Customised::

-

available

-

Working mode::

-

Auto circular seam welder with PLC control

-

Application::

-

solar water heater tank, enamessel tank, LPG/LNG cylinder etc

-

Width and thickness:

-

Customized

-

Features:

-

High efficiency, high precision,Roundness is accurate

-

Function::

-

steel tank welding

-

Weight:

-

Customized

Contacts: Mark Liu

Tel: +86-411-82766928

Fax: +86-411-39015062

Email: Liu@weldcnc.com

Mob/Whatsapp: +86 133 9411 0095

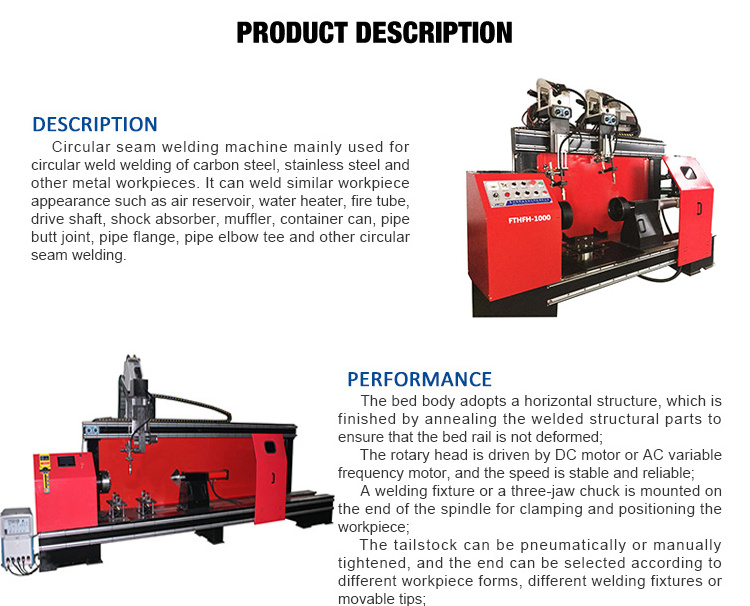

Products Description

Automatic seam welding is a mechanical inert gas shielded tungsten argon arc welding for welding pipes or fittings in fixed positions and circular track welds. The tungsten electrode is assembled in the ring automatic welding machine head, and the driving mechanism drives the circumferential seam welding along the circular path.

The automatic welding of the circumferential seam can be a self-melting method of the base material, or a metal melting ring or a metal welding wire. For automatic seam welding requiring cladding efficiency, the hot wire method can be used to perform additional heating control on the filler wire to achieve higher metal filling speed.

The automatic welding of the circumferential seam can be a self-melting method of the base material, or a metal melting ring or a metal welding wire. For automatic seam welding requiring cladding efficiency, the hot wire method can be used to perform additional heating control on the filler wire to achieve higher metal filling speed.

Feature

♦The welding torch is fixed; the work piece rotating, welding position is horizontal

♦The work piece rotation is driven by clamping, roller bearing bracket

♦The torch is adjustable along the longitudinal beam, adaptable to various welding

♦Machine is PLC control, the work piece rotation adopts AC servo motor speed control, stepless adjustable, improve equipment reliability.

♦The form and parameters of welding can be preset, storing and transferring. Through touch screen human-machine interface can easily change the parameter and state transition.

♦The torch can be adjusted up and down, left and right, dip angle, in order to meet the welding requirements. Complete cylinder girth automatic welding. To ensure concentricity, uniform forming, good appearance, weld penetration and weld width meet the technological requirements, the clamping is convenient. SAW/MIG/MAG welding process; complete in one time welding.

♦The welding torch is fixed; the work piece rotating, welding position is horizontal

♦The work piece rotation is driven by clamping, roller bearing bracket

♦The torch is adjustable along the longitudinal beam, adaptable to various welding

♦Machine is PLC control, the work piece rotation adopts AC servo motor speed control, stepless adjustable, improve equipment reliability.

♦The form and parameters of welding can be preset, storing and transferring. Through touch screen human-machine interface can easily change the parameter and state transition.

♦The torch can be adjusted up and down, left and right, dip angle, in order to meet the welding requirements. Complete cylinder girth automatic welding. To ensure concentricity, uniform forming, good appearance, weld penetration and weld width meet the technological requirements, the clamping is convenient. SAW/MIG/MAG welding process; complete in one time welding.

Equipment Application and Scope

1. Application:

304 stainless steel longitudinal and circumference seam welding

1. Application:

304 stainless steel longitudinal and circumference seam welding

|

cylinder diameter

|

400mm-1200mm

|

|

cylinder length

|

≤ 2500mm

|

|

cylinder wall thickness

|

2mm-6mm

|

2. Job status: work piece welding surface is smooth, the largest seam gap less than 2mm.

3. condition of work piece surface: no pollution, serious corrosion etc.

4. Work piece state before welding: before welding, workpiece are firmly spot welded,the joints are clean.

5. The equipment pneumatically clamps the head and tail of the work piece and turns thework piece automatically.Flanges are welded on a welding positioner. Two sets of systems are using one power source, and the equipment can realize the switch between different welding spot.

3. condition of work piece surface: no pollution, serious corrosion etc.

4. Work piece state before welding: before welding, workpiece are firmly spot welded,the joints are clean.

5. The equipment pneumatically clamps the head and tail of the work piece and turns thework piece automatically.Flanges are welded on a welding positioner. Two sets of systems are using one power source, and the equipment can realize the switch between different welding spot.

MACHINE SUMMARY

Using industry PLC, Touch screen interface, servo motor and AC frequency converter to realize automatic welding.

The machine has the following characteristics:

1. Industrial plc control the operation of the whole machine, the control is accurate and reliable; the operation is simple and convenient.

2. Adopts ac inverter to regulate speed. Realize welding speed steeples adjustment and the adjustment is convenient and reliable, large range, high precision, stable and reliable operation.

3. Using high definition color touch screen, easy to set all kinds of welding process parameters.

4. Plenty of welding process parameters, to acheive full functional automatic welding.

5. Using high quality water cooling push wire welding torch, welding torch with up and down, left and right adjustment and angle adjustment function.

6. Using mechanical positioning. Pneumatic jacking work piece, accurate positioning.

7. In welding process, torch swing, can realize surfacing. Built-up welding automatic multilayer welding process.

8. Process integration is powerful, user according to the work piece welding requirements, has flexible choices.

9. Improve the work eficiency, reduces the labor intensity of the worker.

Circular seam welding machine finished product applied to used in many fields, such as solar water heaters,water tank,oil

tank,LPG tank,pressure vessel,silencer etc.Want to know this circular seam welding machine more solution&applicaton! contact me!

tank,LPG tank,pressure vessel,silencer etc.Want to know this circular seam welding machine more solution&applicaton! contact me!

Product Paramenters

|

Model

|

POWER SUPPLY

|

THICKNESS

(mm) |

DIAMETER (mm)

|

SHRINK HEIGHT

(mm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

MCZFH-500

|

380V 50HZ/220V 60HZ

|

0.1-0.6

|

Φ40-Φ500

|

100-500

|

|

MCZFH-700

|

|

1-1.5

|

Φ40-Φ700

|

150-700

|

|

MCZFH-800

|

|

1.5-2

|

Φ40-Φ800

|

200-800

|

|

MCZFH-1000

|

|

2.5-3

|

Φ40-Φ1000

|

300-1000

|

|

MCZFH-1200

|

|

3-3.5

|

Φ40-Φ1200

|

400-1200

|

|

MCZFH-2000

|

|

3.5-4

|

Φ40-Φ2000

|

600-2000

|

|

MCZFH-2500

|

|

4.5-5

|

Φ40-Φ2500

|

800-2500

|

|

MCZFH-3000

|

|

5.5-6

|

Φ40-Φ3000

|

1000-3000

|

Recommend Products

Hot Searches