- Product Details

- {{item.text}}

Quick Details

-

Shape:

-

Rectangle

-

Colour:

-

Silver or black

-

Nature:

-

Dustproof

-

Feature:

-

Smooth Motion

-

Application:

-

Automation equipment

-

Certification:

-

ISO9001

-

Service:

-

OEM customized service

-

Packaging:

-

Standard Wooden Box Or Carton

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Name:

-

Linear Guides

-

Type:

-

Linear Motion Guideway

-

Shape:

-

Rectangle

-

Colour:

-

Silver or black

-

Nature:

-

Dustproof

-

Feature:

-

Smooth Motion

-

Application:

-

Automation equipment

-

Certification:

-

ISO9001

-

Service:

-

OEM customized service

-

Packaging:

-

Standard Wooden Box Or Carton

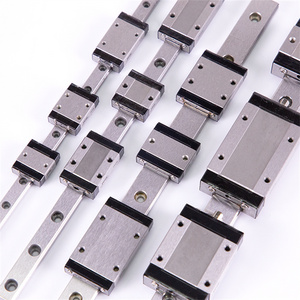

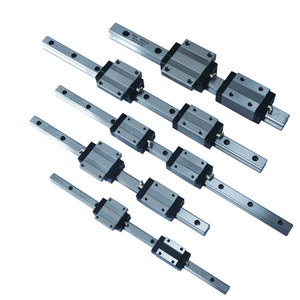

LAPPING LSA-20 20mm Width Linear Motion Guide Rail

|

N ame |

Linear guide rail |

|

Type |

Automatic equipment high speed transmission device |

|

Material |

Heat treated steel |

|

S ize |

Width: 20mm Length: up to 4 meters long, longer stitching |

|

C olour |

Silver or black |

|

S hape |

R ectangle |

|

Certification |

ISO9001 |

|

E ffect |

1. Parallelism and high precision 2. The slider and the guide rail are interchangeable, saving cost 3. High rigidity in all directions 4. Reduce friction |

|

Application area |

Applied to sliding friction guides |

|

S ample |

N o |

|

Delivery period |

7 days |

|

Packing |

1.PE bag, shockproof bubble bag, export standard carton, wooden box 2. According to customer's special requirements |

Difference between models

1. Type A has a longer threaded hole than Type B; Type B can be assembled not only from the top of the slider, but also from the bottom of the slider;

2. Type B is compared with C type, the hole of type C is a through hole, and the hole of type B is a threaded hole;

3. The R type has a smaller width than the A/B/C type;

4. Compared with A/B/C/R type, the LA/LB/LC/LR type has the same section size, the length of the slider is increased, and the number of load steel balls is increased to improve the overall load capacity.

|

Model |

Rail size |

Basic load rating |

Allowable static moment |

Weight |

||||||||||

|

Height H |

Width W |

Pitch P |

E std |

D*h*d |

Dynamic load C KN |

Static load C0 KN |

MP KN*m |

MY KN*m |

MR KN*m |

Slider KG |

Guide KG/m |

|||

|

Single * |

Double* |

Single * |

Double* |

|||||||||||

|

LSA 15 B |

15 |

15 |

60 |

20 |

7.5*5.3*4.5 |

11.8 |

18.9 |

0.12 |

0.68 |

0.12 |

0.68 |

0.14 |

0.18 |

1.5 |

|

LSA 20 B LSA 20 LB |

20 |

18 |

60 |

20 |

9.5*8.5*6 |

19.2 23.3 |

29.5 39.3 |

0.23 0.39 |

1.42 2.23 |

0.23 0.39 |

1.42 2.23 |

0.29 0.38 |

0.4 0.52 |

2.4 |

|

LSA 25 B LSA 25 LB |

23 |

22 |

60 |

20 |

11*9*7 |

28.1 34.4 |

42.4 56.6 |

0.39 0.67 |

2.20 3.52 |

0.39 0.67 |

2.20 3.52 |

0.48 0.63 |

0.62 0.82 |

3.4 |

|

LSA 30 B LSA 30 LB |

28 |

26 |

80 |

20 |

14*12*9 |

39.2 47.9 |

57.8 77.0 |

0.62 1.07 |

3.67 5.81 |

0.62 1.07 |

3.67 5.81 |

0.79 1.05 |

1.09 1.43 |

4.8 |

|

LSA 35 B LSA 35 LB |

34 |

29 |

80 |

20 |

14*12*9 |

52.0 63.6 |

75.5 100.6 |

0.93 1.60 |

5.47 8.67 |

0.93 1.60 |

5.47 8.67 |

1.25 1.67 |

1.61 2.11 |

6.6 |

|

LSA 45 B LSA 45 LB |

45 |

38 |

105 |

22.5 |

20*17*14 |

83.8 102.4 |

117.9 157.3 |

1.81 3.13 |

10.67 16.95 |

1.81 3.13 |

10.67 16.95 |

2.57 3.43 |

2.98 3.9 |

11.5 |

|

LSA 55 B LSA 55 LB |

53 |

44 |

120 |

30 |

23*20*16 |

123.6 151.1 |

169.8 226.4 |

3.13 5.40 |

17.57 28.11 |

3.13 5.40 |

17.57 28.11 |

4.50 6.00 |

4.17 5.49 |

15.5 |

|

LSA 65 B LSA 65 LB |

63 |

53 |

150 |

35 |

26*22*18 |

198.8 253.5 |

265.3 375.9 |

6.11 11.84 |

33.71 57.32 |

6.11 11.84 |

33.71 57.32 |

8.36 11.84 |

8.73 11.89 |

21.9 |

|

Model |

Rail size |

Basic load rating |

Allowable static moment |

Weight |

||||||||||

|

Height H |

Width W |

Pitch P |

E std |

D*h*d |

Dynamic load C KN |

Static load C0 KN |

MP KN*m |

MY KN*m |

MR KN*m |

Slider KG |

Guide KG/m |

|||

|

Single * |

Double* |

Single * |

Double* |

|||||||||||

|

LSA 15 R |

15 |

15 |

60 |

20 |

7.5*5.3*4.5 |

11.8 |

18.9 |

0.12 |

0.68 |

0.12 |

0.68 |

0.14 |

0.18 |

1.5 |

|

LSA 20 R LSA 20 LR |

20 |

18 |

60 |

20 |

9.5*8.5*6 |

19.2 23.3 |

29.5 39.3 |

0.23 0.39 |

1.42 2.23 |

0.23 0.39 |

1.42 2.23 |

0.29 0.38 |

0.30 0.39 |

2.4 |

|

LSA 25 R LSA 25 LR |

23 |

22 |

60 |

20 |

11*9*7 |

28.1 34.4 |

42.4 56.6 |

0.39 0.67 |

2.20 3.52 |

0.39 0.67 |

2.20 3.52 |

0.48 0.63 |

0.52 0.68 |

3.4 |

|

LSA 30 R LSA 30 LR |

28 |

26 |

80 |

20 |

14*12*9 |

39.2 47.9 |

57.8 77.0 |

0.62 1.07 |

3.67 5.81 |

0.62 1.07 |

3.67 5.81 |

0.79 1.05 |

0.86 1.12 |

4.8 |

|

LSA 35 R LSA 35 LR |

34 |

29 |

80 |

20 |

14*12*9 |

52.0 63.6 |

75.5 100.6 |

0.93 1.60 |

5.47 8.67 |

0.93 1.60 |

5.47 8.67 |

1.25 1.67 |

1.45 1.90 |

6.6 |

|

LSA 45 R LSA 45 LR |

45 |

38 |

105 |

22.5 |

20*17*14 |

83.8 102.4 |

117.9 157.3 |

1.81 3.13 |

10.67 16.95 |

1.81 3.13 |

10.67 16.95 |

2.57 3.43 |

2.83 3.70 |

11.5 |

|

LSA 55 R LSA 55 LR |

53 |

44 |

120 |

30 |

23*20*16 |

123.6 151.1 |

169.8 226.4 |

3.13 5.40 |

17.57 28.11 |

3.13 5.40 |

17.57 28.11 |

4.50 6.00 |

4.12 4.91 |

15.5 |

|

LSA 65 R LSA 65 LR |

63 |

53 |

150 |

35 |

26*22*18 |

198.8 253.5 |

265.3 375.9 |

6.11 11.84 |

33.71 57.32 |

6.11 11.84 |

33.71 57.32 |

8.36 11.84 |

6.43 8.76 |

21.9 |

Advantage

1. Adapt to various work too assembled

2. Designed with L-shaped or extended type

3. Self-aligning ability

4. The slider and the guide rail are interchangeable

5. High rigidity in all directions

6. The product is easy to install, easy to operate and fast to transport.

7. High-precision machining: from material optimization to fully automated equipment

8. Quality Assurance: The most efficient laser quality inspection instrument and self-developed slider simulation operation instrument for accuracy inspection

9. Technological innovation: The product has applied for six invention patents and used 27 patents.

Use caution

1. Prevent rust: Keep your hands dry and coated with high quality mineral oil during use. Pay special attention to rust prevention during the rainy season and summer.

2. The installation tool should be suitable: avoid using items such as cloth or short fibers.

3. Keep the environment clean

4. Installation should be carefully