Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

1000 kg

-

Material:

-

SUS304/Cast iron

-

Voltage:

-

380/400/415/440/460 V

-

Treating capacity:

-

2-2500 m3/h

-

Certification:

-

CE Certificate

-

Frequency:

-

50/60 Hz

-

Motor brand:

-

European or Chinese brand

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

GSD

-

Productivity:

-

based on different model

-

Weight (KG):

-

1000 kg

-

Material:

-

SUS304/Cast iron

-

Voltage:

-

380/400/415/440/460 V

-

Treating capacity:

-

2-2500 m3/h

-

Certification:

-

CE Certificate

-

Frequency:

-

50/60 Hz

-

Motor brand:

-

European or Chinese brand

General Introduction

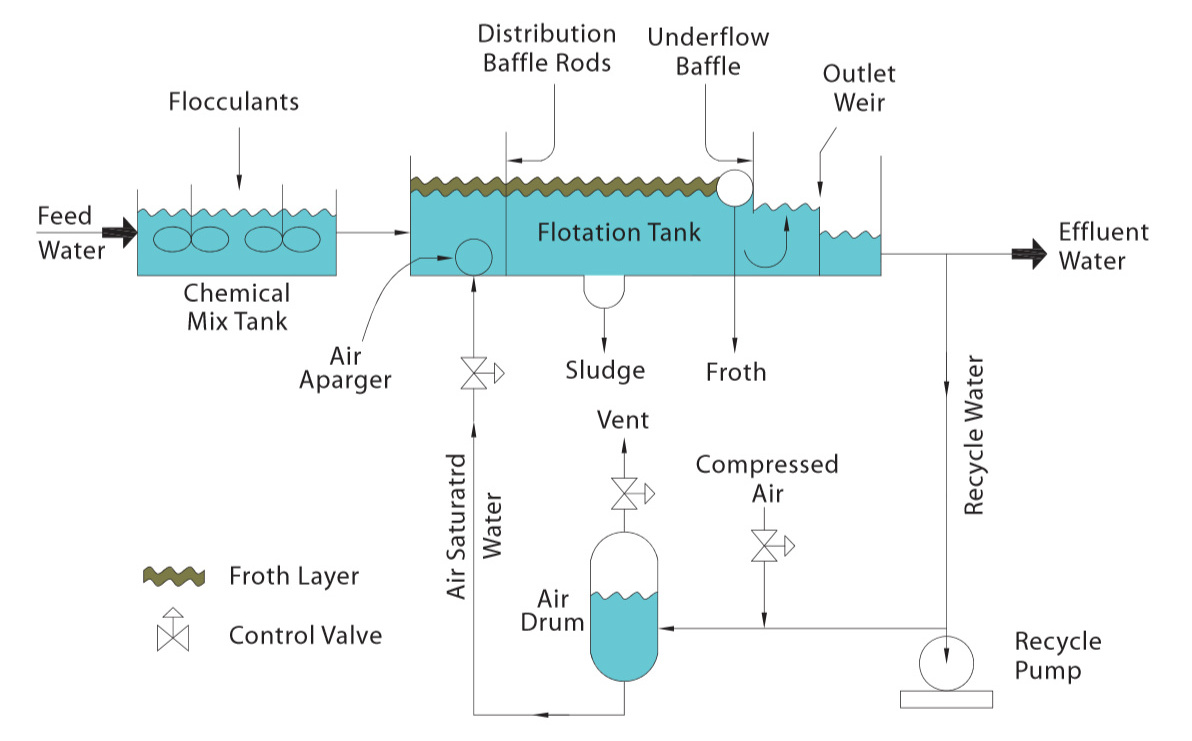

Dissolved air flotation (DAF) is a water treatment process that clarifies wastewaters (or other waters) by the removal of suspended matter such as oil or solids. The removal is achieved by dissolving air in the water or wastewater under pressure and then releasing the air at atmospheric pressure in a flotation tank basin. The released air forms tiny bubbles which adhere to the suspended matter causing the suspended matter to float to the surface of the water where it may then be removed by a skimming device.

Application

1. Separate or recycle waste oil or grease in high centration organic wastewater treatment in paper, painting & dyeing, textile,

leather, pharmaceutical industrial , etc ;

2. Biochemical effluent liquid / solid separation :

- Anaerobic effluent solid /liquid separation ;

- Aerobic (activated, sludge process, contact oxidation, filter) biochemical water solid /liquid Separation ;

- The secondary settling tank effluent treatment ;

3. Farm and slaughter house of cattle, pigs, chickens farm waste water treatment ;

4. Electroplating, painting manufacturing waste water treatment ;

5. Domestics waste water treatment, water purification , etc ;

Features

1. Micro bubble generation technology.

2. Forth circulation and flocculation technology.

3. Provide three series to meet varietal applications and working conditions :

- S-DAF Series: Standard DAF System;Maximum inlet SS concentration is 3000mg/L;Hydraulic load 4~6 m3/m2 h

- SS-DAF Series: Standard sediment DAF system;Maximum inlet SS concentration is 4000mg/L;Hydraulic load 4~8 m3/m2 h

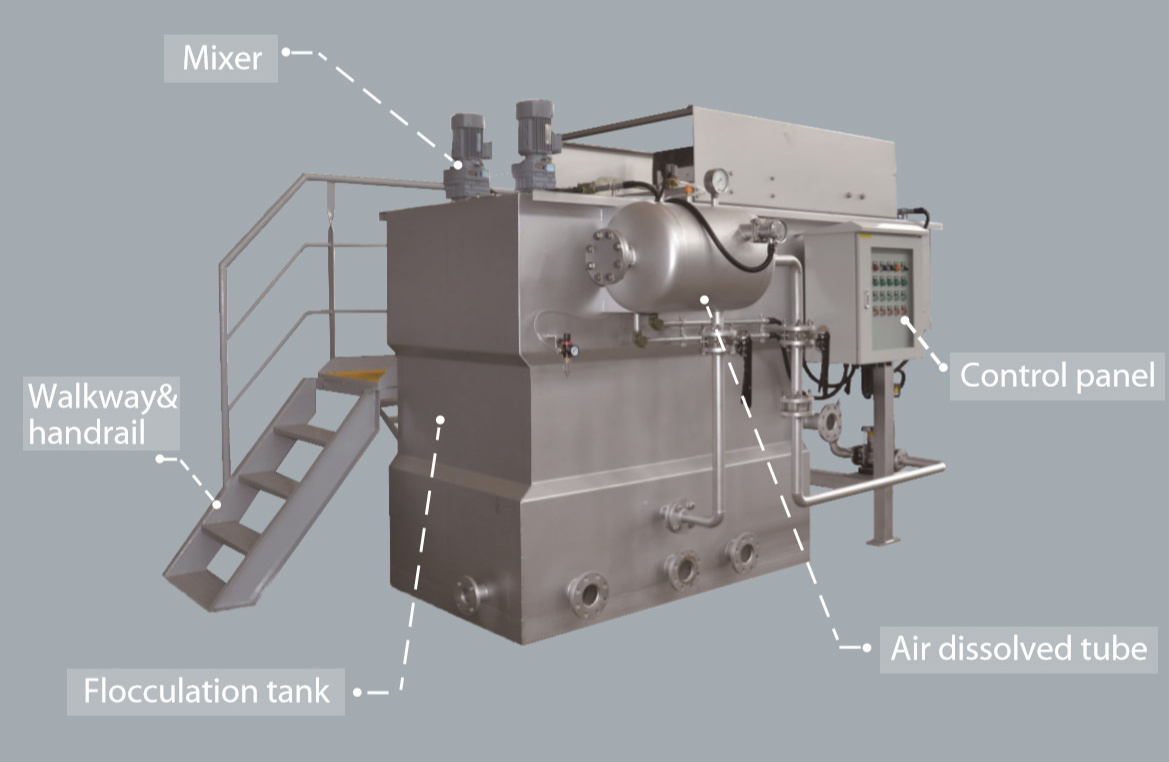

- I-DAF Series: Integrated DAF Which is bombinated of chemical reaction device and DAF system

4. Compact package design which consisted flotation tank , air dissolving tank & recycle pump, froth removal skimmer and flocculation mixing system ( for I-DAF series) , assembly in one unit , easy to installation and transportation .

5. Design utilize parallel plate packing material to provide more separation surface and there fore to enhances the separation efficiency of the unit ( for high capacity Model ) ;

6. “W” type sludge sedimentation hopper, no dead zone designed to make sludge discharge smoothly ( for SS-DAF Series).

7. High operation stability and reliability , automatic froth layer removals solid content up to 3000mg/L .

8. Provide varietal high corrosion resistant materials for main structure.

• Carbon steel coated by bituminous paint

• Carbon steel with FRP shell liner

• Stainless steel SS304

9. Integrated walking way assembly by high corrosion resistant material grating plate with carbon steel stair and handrail . Provide varietal standard connection flanges , such as JIS, DIN, GB, ANSI, etc.

10. Standard control: On-site manual/automatic control, reserve remote operation, total fault signal (DCS), air floatation with low water level protection switch.

11.Easy to up grade by custom control systems ( PLC, HMI, SCADA or remote control ).

Structural Composition

Performance Parameter

S-DAF Series: standard DAF

SS-DAF Series: standard sedimentation DAF

I-DAF Series: integrated DAF

Related products (you may be interested in)

| SAR surface aerator | AR submersible aerator | MA submersible mixer |

| MH hyperboloid mixer | GRB roots blower | RSD disc diffuser |