- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

3*380V or by customer

-

Dimension(L*W*H):

-

3100*2500*2700

-

Weight (T):

-

1 T

-

Power (kW):

-

customized

-

Name:

-

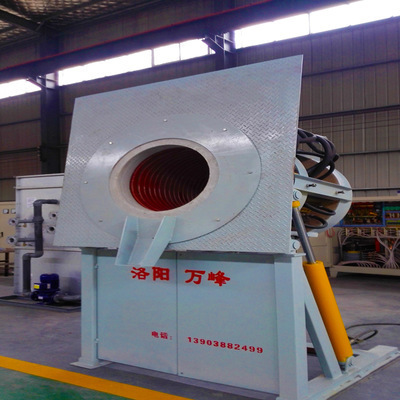

Induction melting Furnace

-

Capacity:

-

50kg-10ton

-

Melting material:

-

steel,iron,brass,aluminum,zinc etc

-

Color:

-

Gray or by customer

-

Model:

-

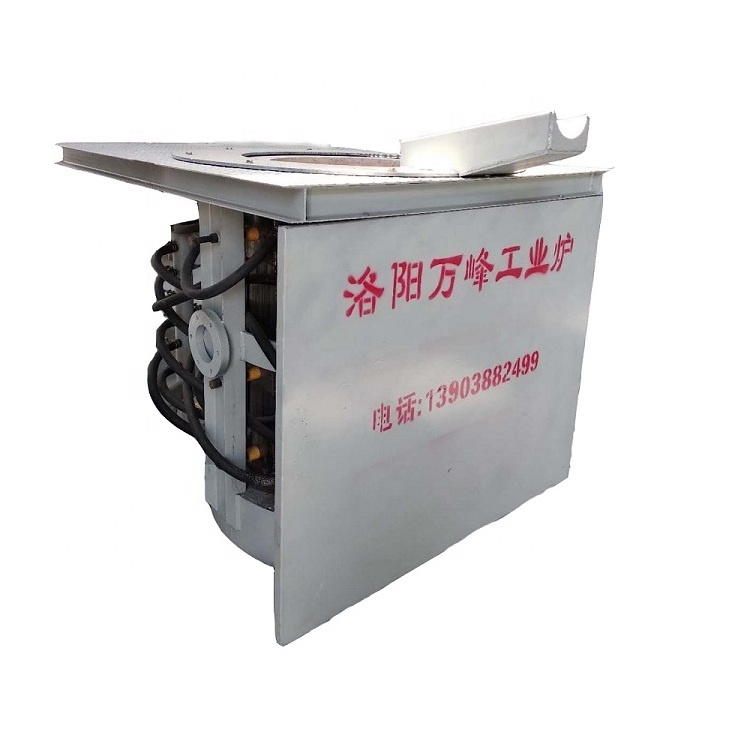

GWJ-steel shell

-

Feature:

-

Energy-saving

-

Function:

-

Melting magnetic metal

-

Frequency:

-

Medium Frequency

-

Working Temperature:

-

700-2300,adjustable

-

Power(W):

-

100-8000KW

Quick Details

-

Place of Origin:

-

Henan, China

-

Marketing Type:

-

Hot Product 2022

-

Brand Name:

-

wanfeng

-

Voltage:

-

3*380V or by customer

-

Dimension(L*W*H):

-

3100*2500*2700

-

Weight (T):

-

1 T

-

Power (kW):

-

customized

-

Name:

-

Induction melting Furnace

-

Capacity:

-

50kg-10ton

-

Melting material:

-

steel,iron,brass,aluminum,zinc etc

-

Color:

-

Gray or by customer

-

Model:

-

GWJ-steel shell

-

Feature:

-

Energy-saving

-

Function:

-

Melting magnetic metal

-

Frequency:

-

Medium Frequency

-

Working Temperature:

-

700-2300,adjustable

-

Power(W):

-

100-8000KW

Product Description

We are a factory, we can produce

20KG-20T

Metal Smelting Furnace.

Medium Frequency Induction Furnace Mainly is used to

melt steel, iron, copper, aluminum and alloy,zinc,lead,etc.

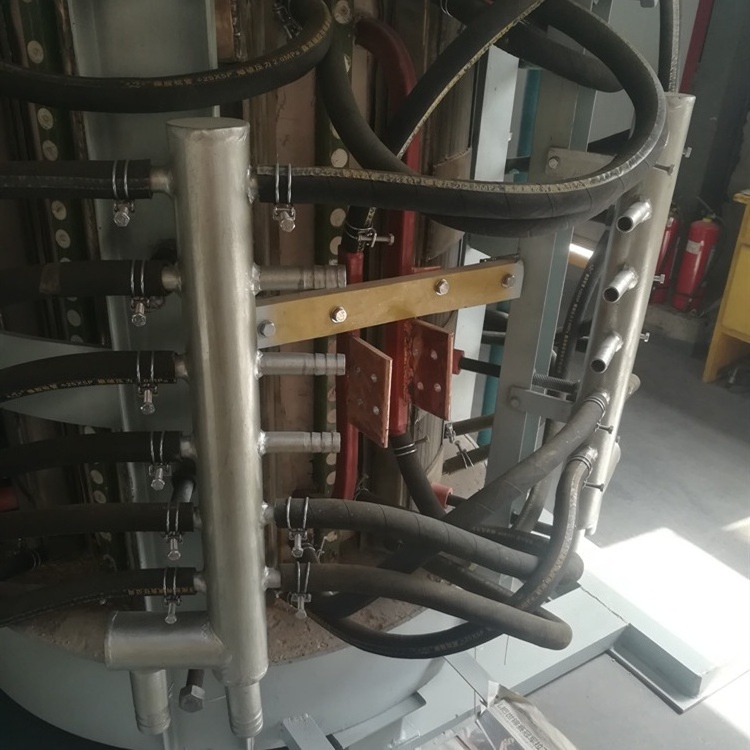

The induction melting furnace has good electromagnetic stirring and melting metal is conducive to uniform temperature.

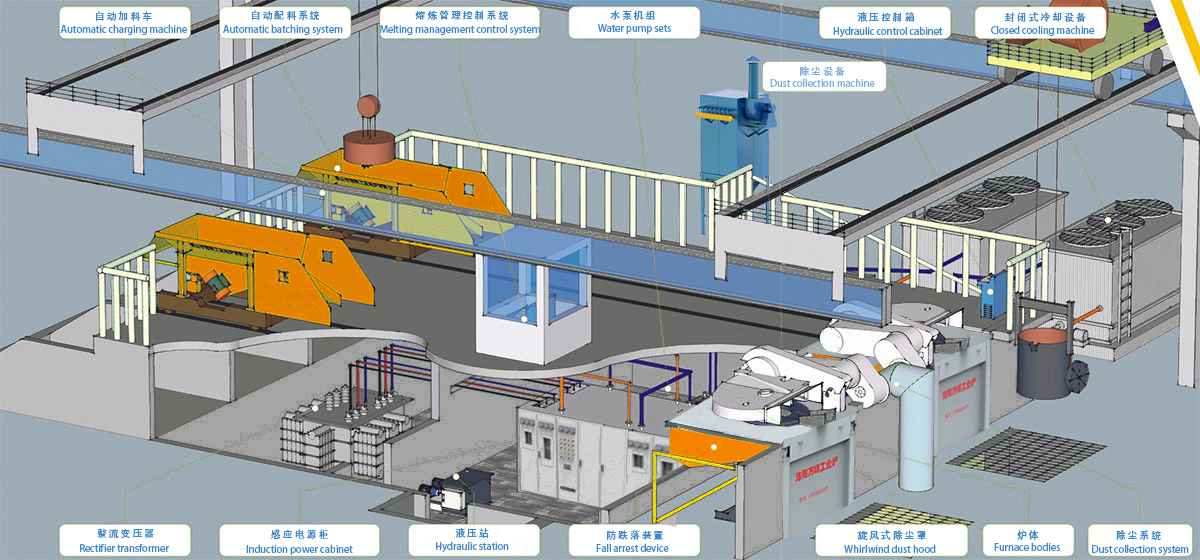

T

he Layout Diagram of Medium Frequency Furnace

Standard Configuration of Furnace (Steel shell)

suggested Reducer tilting (≤2T)

suggested Hydraulic tilting (≥2T)

Type1:

Steel shell furnace without cover

Type2:

Steel shell furnace with cover

The

furnace

color can be customized

Type3:

Steel shell furnace with cyclone dust hood

Technological Process

Casting Production Line

1.Metal Scrap---2.Melting Furnace---3.Casting Machine---4.Finished Product

Product Details

Parameters

|

|

Rated capacity

|

Rated power(KW)

|

Rated frequency(Hz)

|

Input voltage(V)

|

|

Steel

Melting

Furnace

(1600℃)

|

100kg

|

100

|

2500

|

|

|

|

150kg

|

160

|

1000

|

|

|

|

250kg

|

250

|

|

|

|

|

500kg

|

400

|

|

|

|

|

750kg

|

500

|

|

|

|

|

1T

|

1000

|

|

|

|

|

2T

|

1400

|

700

|

|

|

|

3T

|

2000

|

500

|

|

|

|

5T

|

2500

|

|

|

|

|

8T

|

4000

|

|

6 phase,50Hz,850V

|

|

Aluminum

Melting

Furnace

(850℃)

|

150kg

|

100

|

|

|

|

|

300kg

|

200

|

|

|

|

|

500kg

|

300

|

|

|

|

|

750kg

|

400

|

|

|

|

|

1T

|

600

|

|

|

|

|

1.5T

|

750

|

700

|

6phase, 50Hz,380V

|

|

|

3T

|

1800

|

500

|

6phase, 50Hz,1000V

|

|

|

5T

|

2500

|

300

|

|

|

Copper

Melting

Furnace

(1200℃)

|

150kg

|

100

|

1000

|

|

|

|

250kg

|

160

|

|

|

|

|

350kg

|

160

|

|

|

|

|

500kg

|

300

|

|

|

|

|

750kg

|

400

|

|

|

|

|

1T

|

600

|

1000

|

3 phase, 50Hz,380V

|

|

|

2T

|

1000

|

700

|

6 phase, 50Hz,750V

|

|

|

3T

|

1600

|

500

|

750V/1000V

|

|

|

5T

|

2000

|

300

|

|

Customer Support

Customer Site Case

-------------------------------

Customer Visit

--------------------------

New Technology

Melting Management System of WANFENG

The melting management control system mainly monitors the operation of intermediate frequency furnace system online. The system integrates data acquisition and adjustment, waterway inspection, temperature control, remote diagnosis and other functions, and isolates the control function and status information from the main equipment, which is convenient and safe.

Data collection and adjustment: directly collect voltage, current, frequency and other electrical parameters of each link, display and save in real time, customers can realize remote control operation through remote control cabinet.

Data collection and adjustment: directly collect voltage, current, frequency and other electrical parameters of each link, display and save in real time, customers can realize remote control operation through remote control cabinet.

1.Waterway inspection

: monitor the cooling water temperature of variable frequency cabinet and furnace body to avoid burning of

electrical parts.

2.Temperature control : PID temperature control system, real-time sensitive adjustment of melting temperature.

3.Remote diagnosis : For the operation state of the intermediate frequency furnace system, data retention and analysis are carried out in the "company headquarters" through the "Internet of things" to realize the remote diagnosis function. When there is a failure and shutdown, it can be dealt with in the first time.

electrical parts.

2.Temperature control : PID temperature control system, real-time sensitive adjustment of melting temperature.

3.Remote diagnosis : For the operation state of the intermediate frequency furnace system, data retention and analysis are carried out in the "company headquarters" through the "Internet of things" to realize the remote diagnosis function. When there is a failure and shutdown, it can be dealt with in the first time.

Must-read!

Recommend Products

Why Choose Us

Rich

in 28 years manufacture

experience

Reliable

on 10 years exporting

experience

Reassuring

at turnkey project and 24hr

online support

Certifications

-----------------------------

Packing & Delivery

---------------------------------

24H Customer Service

Online Service

Vedio Call Service

Oversea Service

Contact Us:

*Contacts

:

Marcia Xu

*

TEL/Whatsapp/Wechat:

+86 18039411986

*Email:

yorkzhang@wanf.cn

*Address:

The

southern tip of Jianxi Industrial Park. Jianxi District, Luoyang, China

Hot Searches