- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customer's Requirement

-

Dimension(L*W*H):

-

1680*1140*1890mm

-

Weight (KG):

-

1000

-

Power (kW):

-

1.5

-

Model:

-

MY820 200X500MM

-

table size:

-

200x500mm

-

movement:

-

auto hydralulic movement

-

Key words:

-

Mini Surface Ginder

-

Product name:

-

Surface Ginder MY820

-

Usage:

-

General

-

Max. Grinding Length:

-

480mm

-

Weight:

-

900kg

-

Max. Grinding Diameter:

-

200mm

-

Power:

-

1.5kw

Quick Details

-

Wheel Size(mm):

-

200

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

chunjiang

-

Voltage:

-

Customer's Requirement

-

Dimension(L*W*H):

-

1680*1140*1890mm

-

Weight (KG):

-

1000

-

Power (kW):

-

1.5

-

Model:

-

MY820 200X500MM

-

table size:

-

200x500mm

-

movement:

-

auto hydralulic movement

-

Key words:

-

Mini Surface Ginder

-

Product name:

-

Surface Ginder MY820

-

Usage:

-

General

-

Max. Grinding Length:

-

480mm

-

Weight:

-

900kg

-

Max. Grinding Diameter:

-

200mm

-

Power:

-

1.5kw

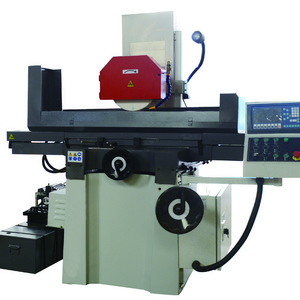

Mini Auto Hydraulic Surface Ginder Price MY820

Grinding Machine/Grinder (MY820) 200x500mm

High rigidity H-frame column with spindle center to table for extra clearance under the wheel.

* Enhanced ribbed full cast iron base provides the best anti-vibration foundation with greater stability and rigidity

*Enlarged spindle housing for heavier grinding

* V3 grade spindle motor for powerful output to achieve prescicion work standards and better grinding capability.

* Cartridge spindle w/4 preloaded class 7 (P4) bearing and run our of taper nose better than 0.00060 T. I. R. Provides quiet, vibration free operation for better workpiece accuracy.

* MY820: X axis auto hydraulic transmission, Y axis manual transmission, Z axis manual transmission.

* Flat+V type linear table ways for easy and smooth longitudinal movements and double V shape saddle ways for rigidity

* Manual lubrication system provides lubrication to all necessary mechanism saddle&column ways, bearings and lead screws for better machine performance and less maintenance.

* Convenient control panel including all buttons and switches.

*Digital readout system two axis (Z& Y axis) digital readout

The min. Digital readout amount: 0.001-0.005mm

Mini Auto Hydraulic Surface Ginder Price MY820

| Main specifications | MY820 | ||

| Max. workpiece to be Ground ( L× W× H) | mm | 500× 200× 320 | |

| Max. Grinding Length | mm | 520 | |

| Max. Grinding Width | mm | 220 | |

| Distance From Table Surface To Spindle Center | mm | 490 | |

| Slide way | V-type rail with Steel-ball | ||

| V-type rail with Steel-ball | Kg | 150 | |

| Table Size (L× W) | mm | 480× 220 | |

| Number of T -Slot | mm× n | 12× 1 | |

| Speed OF Working Table | m/min | 3-23 | |

| Cross Feed On Handwheel | mm | 0.02/div. 2.5/rev. | |

| Vertical Feed On Handwheel | mm | 0.01/div. 1.25/rev. | |

| Wheel Size (dia. × width× bore ) | mm | 200× 16× 31.75 | |

| Spindle Speeds | 50Hz | rpm | 2850 |

| Spindle Motor | Kw | 1.1 | |

| Hydraulic station motor | Kw | 1.5 | |

| Working Pressure | Mpa | 3 | |

| Max. Capacity | L/min | 18 | |

| Minimum Of Numerical | L | 80 | |

| Coolant Pump | Kw | 0.04 | |

| Minimum of Numerical Display | mm | 0.001 | |

| Machine Size (L× W× H) | mm | 1680× 1140× 1800 | |

| Packing Size (L× W× H) | mm | 1140× 1630× 1960 | |

| Gross Net weight | T |

O. 85 0.75 |

|

Standard Appendix:

(1) tool box

(2) balancing stand and bar

(3) handwheel nut

(4)flange wrench

(5) screwdriver

(6)Balancing screw

(7)open-end wrench

(8)inner hexagon spanner

(9) wheel dresser holder

(10) machine stand pad

(11) wheel flange

(12) wheel dresser

(13) chuck.

Mini Auto Hydraulic Surface Ginder Price MY820

Optional accessories:

(1)tiltable permanent chuck

(2) demagnetizer

(3) overhead parallel dresser

(4) angle dresser

(5) radius dresser

(6) precision vice

(7) dust suction device

(8)digital readout system

(9) working light

(10)wheel flange.

Mini Auto Hydraulic Surface Ginder Price MY820

- CJ Machinery always insist on the concept of providing our customers the most enjoyable metal working experiences. Every need or request would be answered at our best considering customer's greatest interests.

- CJ Machinery values each relationship among our worldwide customers and hopes every unique requirement of our customers could be satisfied

.

At present our main products range as following

Surface grinding machine

Manual Surface grinder

M618A, M820, M250

Auto electric Surface grinder

MD618A, MD820

Auto Hydraulic Surface grinder

MY820, MY250, MY3060, MY3075, M7125A, M7135A, M7140A

Full Auto (PLC) hydraulic Surface grinder

SGA2550AHD, SGA3063AHD, SGA4080AHD, SGA40100AHD, SG50100AHD

Wheel Head Moving Surface grinder

M7132, M7140, M7150, M7160, M7163

Universal cylindrical grinder

M1420, M1432B, M1450

Shot blast machine

Q324, Q326, Blast wheels/impellers, shot blasting turbines system

Lathe machine

Combo Lathe milling machine:

WMP250V, WMP280V, WMP290V, HQ500, HQ800

Bench lathe:

WM250V, WM280V, WM290V, CQ6236G, CQ6230A, C0632C, GH1440K, GH1440A, C6236

Industrial lathe

CD6241, C6241/C6246/C6251/C6256, C6266/C6280, C6236C/C6240C/C6250C/C6260C, CD6240/CD6250/CD6260B(C), C6250/C6266B (C), CS6240/CS6250/CS6266B (C), CQ6280C, CY6266/CY6280

Heavy duty lathe

CW6183C/CW6293C, CW6180/CW62100, CZ6280/CZ62100C.

CNC lathe

CK6132, CK6136, CK6140,CK6146, CK6150, CK6156,CK6166, CK6180

Milling machine

Drilling milling machine

ZX45, ZX7045, ZAY7045FG, ZX50C, ZX7550C/ZX6350C, ZX7550CW/ZX6350ZA

Turret milling machine

X6323/X6325/X6330/X6333 ( MF1V/MF5V/MF6V/MF7V), X6336. X6332Z,

Knee type milling machine:

X6136A, XW6136, XL6032CL, X5032W, XZ5150, XA7140

Swivel head type milling machine :

LM1450A, XQ6226B, X6432, X6436

Tool milling machine

X8130A, X8140A

CNC milling machine

VMC1000, VMC800 VMC850 XK7136C, VMC850B, XH7132A, XH7125

Vetical drilling machine

Z5045, Z5045C, Z5045C-1,Z5140B,Z5150B

Saw Machine

Band saw

BS-712N, G4017, G5020, G5025, G5027

Horizontal Saw

GH4220, GH4228, GH4235,GH4240, GH4250, GH4280

EDM and wire cutting machine

EDM450, EDM540, EDM650,DK7732,DK7740, DK7750,DK7763

Shaper machine, slotting machine

B635A, BC6050, BC6063, BC6066,

Hydraulic press:

HP(B)-30, HP(B)50/HP(B)63, HP(B)-100, HP-10S, HP-20S

Shearing machine

manual shearing machine

mechanical shearing QH11D,

hydraulic shear QC11Y, QC12Y

Bending /foldingmachine

Manual bending machine WH06, ESF1020,

QF28Y corner notching,

ERBM30/40/50/65HV section bending machine,

Hydraulic folding machine W62K,

hydraulic press brake WC67Y, WE67K

Rolling machine:

Manual rolling machine,

ESR electric rolling machine,

Mechanical rolling machine W11, W11Y, W12S,

Q35Y Iron workers, and all kinds of auto maintenance and vehicle equipment and machine accessorie.

More Credit to customer, More customer, More and More Business Cooperation!

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

WhatsApp: 0086 13851005559

- Please do not hesitate to contact us for more details or data sheets, all other questions would be fully welcomed too.

- Latest MACHINERY CATALOGUES are available now! Download them on our official website or directly contact us.

- CJ Machinery always insist on the concept of providing our customers the most enjoyable metal working experiences. Every need or request would be answered at our best considering customer’s greatest interests.

- CJ Machinery values each relationship among our worldwide customers and hopes every unique requirement of our customers could be satisfied .

CE certificate