Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

230-391-5

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

SHUODE

-

Model Number:

-

WD

-

Type:

-

Manual

-

Item name:

-

polyurethane spray foam

-

Cuttable time (30mm diameter (minute):

-

Approx.60

-

Certificate:

-

ISO9001

-

Optimal Application Temp.(℃):

-

+5~+35

-

Min. Application Temp.(℃):

-

+18~+25

-

Tensile Strength(Aluminum Plate)(KPA):

-

120

-

Temp. Resistance(Long Term)(℃):

-

-30~+80

-

Temp. Resistance(Short Term)(℃):

-

-40~+110

-

Expansion Multiple(time):

-

Max.70

-

Density(KG/M3):

-

17±6

Quick Details

-

CAS No.:

-

7085-85-0

-

Other Names:

-

insulation foam spray

-

MF:

-

Mixture

-

EINECS No.:

-

230-391-5

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

SHUODE

-

Model Number:

-

WD

-

Type:

-

Manual

-

Item name:

-

polyurethane spray foam

-

Cuttable time (30mm diameter (minute):

-

Approx.60

-

Certificate:

-

ISO9001

-

Optimal Application Temp.(℃):

-

+5~+35

-

Min. Application Temp.(℃):

-

+18~+25

-

Tensile Strength(Aluminum Plate)(KPA):

-

120

-

Temp. Resistance(Long Term)(℃):

-

-30~+80

-

Temp. Resistance(Short Term)(℃):

-

-40~+110

-

Expansion Multiple(time):

-

Max.70

-

Density(KG/M3):

-

17±6

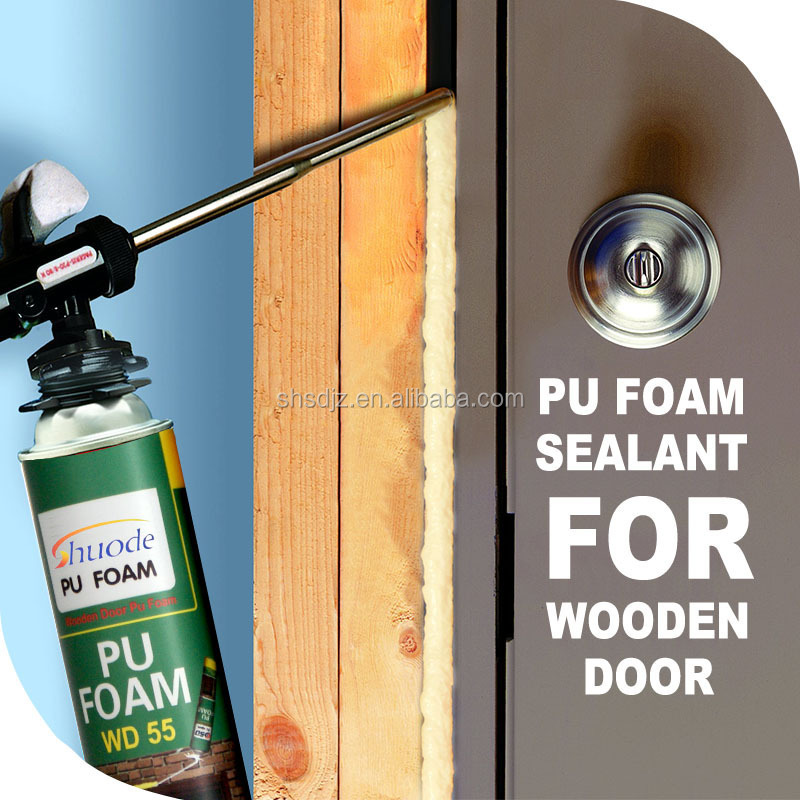

polyurethane spray foam polyurethane sealant

Wooden type polyurethane foam is a one component, economical type and good performance Polyurethane foam. It is fitted with a plastic

a dapt e r head for use with a foam application gun or a straw. The foam will expand and cure by moisture in the air. It is used for a wide range

of building applications. It is very good for filling and sealing with excellent mounting capacities, high thermal and acoustical insulation.

Specification:

|

Model |

Wooden Door No. 1 |

Wooden Door No. 2 |

|

Consistency |

Polyurethane |

Polyurethane |

|

Density( KG/M3 ) |

1 8 ±6 |

1 9 ±6 |

|

Expansion Multiple( time ) |

Max. 70 |

Max. 73 |

|

Cuttable Time( 30mm diameter )( minute ) |

Approx. 60 |

Approx. 60 |

|

Optimal Application Temp.( ℃ ) |

+5~ +35 |

+5~ +35 |

|

Min. Application Temp.( ℃ ) |

+18~ +25 |

+18~ +25 |

|

Min Temp. of can( ℃ ) |

10 |

10 |

|

Tensile Strength( Aluminum Plate ) (KPA) |

120 |

120 |

|

Dimensional Stability |

±3% |

±3% |

|

Water Permeability |

none |

none |

|

Tack- free Time( minute ) |

Max. 10 |

Max. 10 |

|

Temp. Resistance( Long Term )( ℃ ) |

-30~ +80 |

-30~ +80 |

|

Temp. Resistance( Short Term )( ℃ ) |

-40~ +110 |

-40~ +110 |

|

Contents of formaldehyde and benzene |

None |

None |

|

Thermal Conductivity( W/M.K ) |

0.042 |

0.042 |

|

Corrosion Resistance |

Qualified |

Qualified |

|

Fire Retardant Factor |

\ |

\ |

|

Toxicity after curing |

None |

None |

|

Shelf Life( 18 ~ 22℃, store upside) (Month) |

9 |

9 |

Scope of Application:

polyurethane foam

It can be used to fill the edges of doors or windows or expansion clearance of the engineering;to prevent water or leakage;to seal and insulate the pipe lines,wire connectors and the sockets in the cornert of the water and electricity projects;to caulk all kinds of slots,cracks,holes and openings to prevent leakage;and to fill the exterior wall's or curtain wall's slot;to complete the roof edges;to contect the ceiling,the decotated board and the door panel;the seal the cold store and the refrigerator car to preserve heat; to caulk the cracks for installing the air aondition or sanitary wares,or to pack the gardening sceneries,the ikebana or the frangible'or to isolate the places from noises,heat or leakage.

Use by gun:

polyurethane foam

Step 1. Shake the can at least 30 times.

Step 2. Clean and dampen the place where will be filled.

Step 3. Place the can upside down and screw it on the adapter; counter clock wisely open the control valve to have a appropriate flow.

Step 4. Spray the foam from down to up; fill 80% volume of the gap is ok.

Step 5. The tack-free time is about 10 minutes; the foam can be processed after 1 hour.

Step 6. The foam can be trimmed by knife; then its surace can be processed by cement, coating, paint, silicone and so on.

Use by

screw

:

polyurethane foam

Step 1. Shake the can at least 30 times.

Step 2. Clean and dampen the place where will be filled.

Step 3. Place the can upside down and screw the tube on the can ; counter clock wisely open the control valve to have a appropriate flow.

Step 4. Spray the foam from down to up; fill 80% volume of the gap is ok.

Step 5. The tack-free time is about 10 minutes; the foam can be processed after 1 hour.

Step 6. The foam can be trimmed by knife; then its surace can be processed by cement, coating, paint, silicone and so on.

![[XiBao]pu polyurethane foam sealant adhesive 750ml spray foam insulation pu foam spray](https://cdn.bestsuppliers.com/seo_products_img/cn1557957669cuir/1601030674794/2dbeb409b6ab382695011d23bafc9986.jpg!/rotate/180/sq/300)