- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Roll material:

-

High grade No.45 forged steel,with 5 nm chrome coated

-

Control system:

-

Totally automatic PLC Taiwan Delta or Siemens control system

-

Roll stations:

-

15 rows

-

Shaft material:

-

High grade No.45 forged steel,with 5 nm chrome coated

-

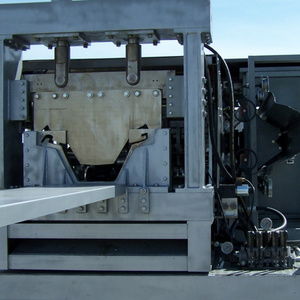

Cutting system:

-

Automatic hydyaulic cutting

-

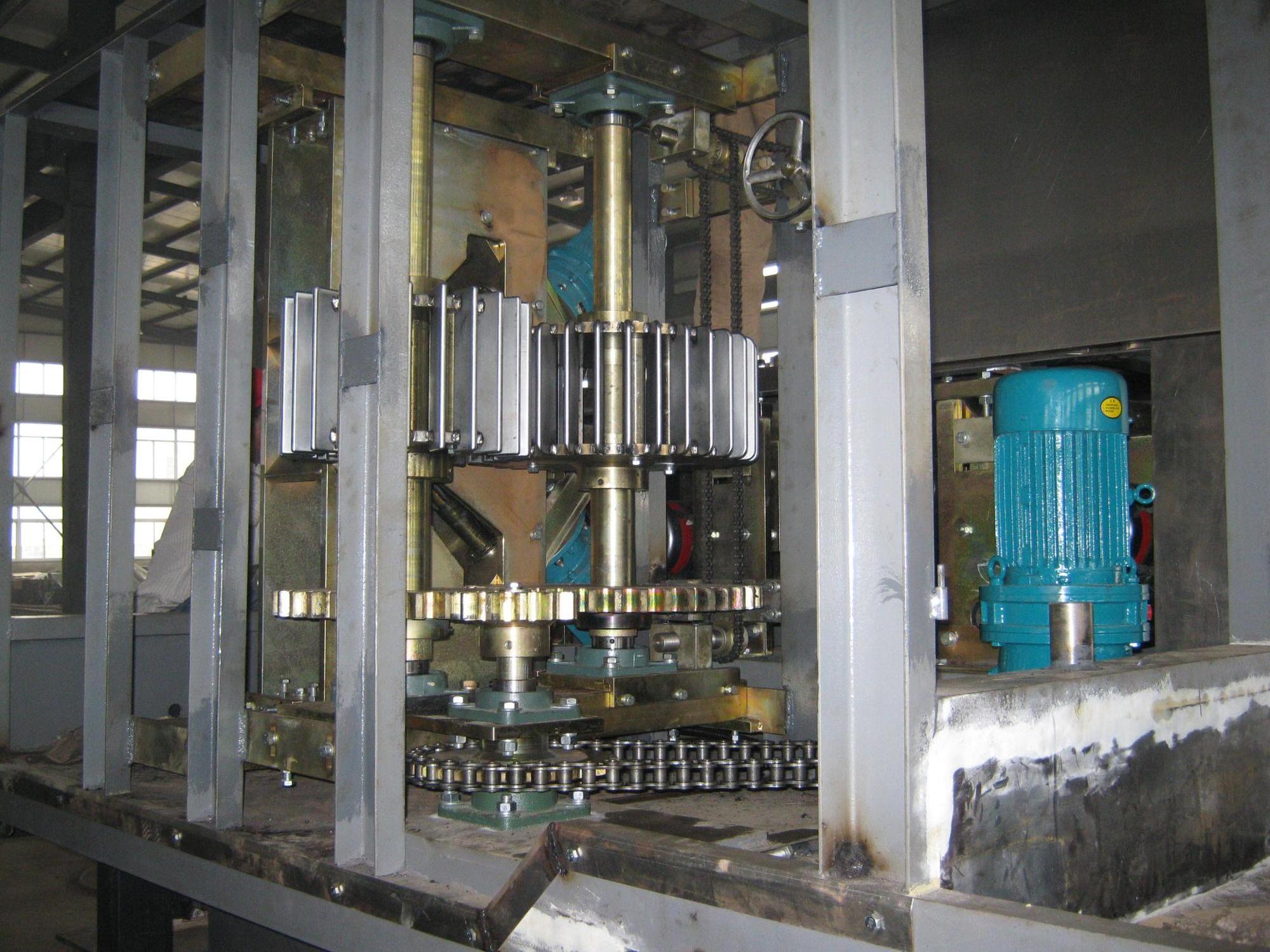

Kind of drive:

-

Chain drive

-

Frame material:

-

300 H-high grade steel

-

Cutting blade material:

-

Cr12 mould steel with quenched treatment

-

Certification:

-

CE &ISO

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Glaze Steel

-

Production Capacity:

-

8-12M/Min

-

Place of Origin:

-

China

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Roll material:

-

High grade No.45 forged steel,with 5 nm chrome coated

-

Control system:

-

Totally automatic PLC Taiwan Delta or Siemens control system

-

Roll stations:

-

15 rows

-

Shaft material:

-

High grade No.45 forged steel,with 5 nm chrome coated

-

Cutting system:

-

Automatic hydyaulic cutting

-

Kind of drive:

-

Chain drive

-

Frame material:

-

300 H-high grade steel

-

Cutting blade material:

-

Cr12 mould steel with quenched treatment

-

Certification:

-

CE &ISO

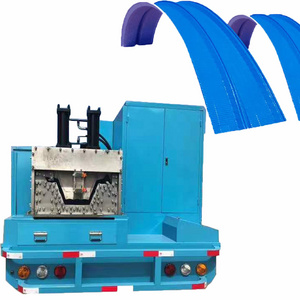

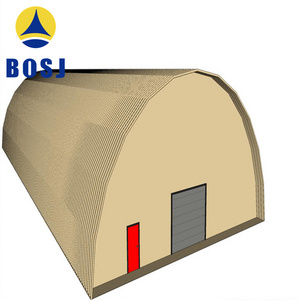

large span curve roof forming machine

914-610 k type long span large size roll forming machine

Other machines also may help you

| metal roof tile roll forming machine | double layer roll forming machine |

|

|

| light keel roll forming machine | roller shutter roll forming machine |

Our machine has passed CE and ISO certificated

Before loading ,we test the full machine line with long steel coil ,not shot one!

C.Q ----cost performance quality series

5m auto stacker ( can be chosed)

Service:

We have professional team to make different kinds of roll forming machines for our customers,

from designing, processing,assembling, debugging, delivery.

We can send our technicians to customer's factory for installation, and teach customer's workers how to use the machines.

If there is any problems happened to the machine, we will provide solution at once.

Hope we could establish win-win business relations in the soon future!

FAQ:

Q:How is this machine's service life?

A:In the normal maintenance,the service life at least 8 years.

Q:How to maintenance?

A:If using frequently,best coating lubricant on the chain and two ends of the shaft every month,replace the hydraulic oil every 1-2 years.

Q:What can you do if the machine broken?

A:Our machine's warranty period is 1 year,if the broken 914-610 k type long span large size roll forming machine parts can't repair,we can free send the new parts replace the broken parts to you except the solenoid valve,the solenoid valve you must pay the express cost yourself.if after warranty period,we can through negotiation

for to solve the problems,and we supply the technical support for the whole life of the equipment.

Q:Can you be responsible for transport?

A:Yes,please tell me the destination port or address.we have rich experience in transport.

Q:can you make the machine according to my design or p

roduction

type?

A: Yes. We have an experienced team for working out the most suitable design and production plan for the machine that you are going to book with us.

Q:How many workers operate this machine to manufacture?

A:Only 1-2 worker.

Q:Can you supply the raw materials?

A:Yes,we can supply the galvanized steel coil,color steel coil,and aluminum coil.