steel frame structure, easy for routine maintenance, large size H-beam, or square steel pipes constitute the basic structure of the furnace frame, the overall structure is simple, strong, maximum inclination 95 degrees.

- Product Details

- {{item.text}}

Quick Details

-

Weight (T):

-

20 T

-

Power (kW):

-

2000

-

Power:

-

2000KW

-

Furnace type:

-

Steel Frame

-

Application:

-

aluminum alloy

-

Power consumption:

-

400KWH

-

Feature:

-

Pouring

-

Temperature control:

-

PLC+ Touch Sreen

-

Input Voltage:

-

660V

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Rongke

-

Voltage:

-

3200V

-

Weight (T):

-

20 T

-

Power (kW):

-

2000

-

Power:

-

2000KW

-

Furnace type:

-

Steel Frame

-

Application:

-

aluminum alloy

-

Power consumption:

-

400KWH

-

Feature:

-

Pouring

-

Temperature control:

-

PLC+ Touch Sreen

-

Input Voltage:

-

660V

Company Introduction

Our factory products Induction furnace.

Furnace body working simultaneously 20 minutes with highest efficiency and have patent of Mixed Hertz induction stirring melting furnace for alloy casting. Series inverter steel melting 550KWH per ton. New design billet induction heating equipment can be less than 300KWH per ton. Graphene new materials manufacturing furnace with technology can be supplied.

After 30 years development, upgraded to Henan Rongke Electrical Manufacturing CO., LTD. new factory more than 7000 square meters.

Certifications

Product Description

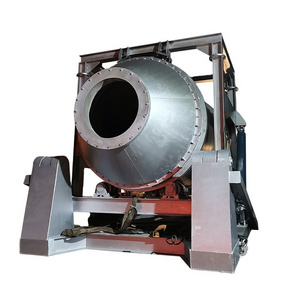

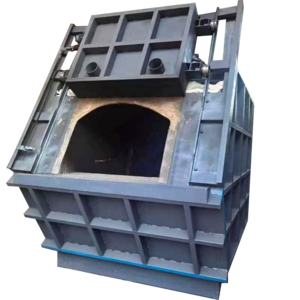

steel shell yokes induction furnace:

steel framed induction furnace

: steel shell furnace body, furnace frame, furnace cover, tilting furnace oil cylinder, dust cover with furnace cover and hydraulic cylinder, inductor, yoke, high-pressure carbon-free rubber pipe, furnace mouth and bottom pouring fixed material, a complete set of stainless steel water inlet distributor, backwater collector and clamp, etc., including wall-mounted water inlet and outlet.

Description

Induction copper coil

Solid, durable and highly conductive T2 copper tube make

. Water-cooled coil and the effective coil are integrally formed by a copper tube without segmentation. The induction coil are insulated and adopt advanced segmentation technology. Insulating sheet implanted between adjacent induction coils. After the insulating varnish sprayed, it becomes a complete structure, and pressed by the upper and lower steel structures in the furnace body, the overall structure is firmed without deformation problem. The coil need supplied with cooling water from a plurality of water paths and evenly distributed. Outside the coil wound with

insulating material. The inter-turn arc-shaped insulating spacers ensure uniform coil spacing and facilitate moisture removal.

Yokes

South Korea's Pohang, or WISCO, Baosteel's silicon steel sheet. Uniformly applied to the brace bolts and provide maximum pressure to the coil to ensure a long working life of the lining. The yoke is made of high-quality cold-rolled silicon steel sheet. The tolerance of the shearing edge of the silicon steel sheet after processing <±0.1mm. The bending degree after assembly meets the requirements of TB/T4280-93 to ensure the coil and the yoke arc shape precision fit. At the same time, multiple sets of yoke fastening devices are firm and reliable, easy to assemble, disassemble, adjust and repair, and evenly distributed along the circumference; the liner between the yoke and coil is made of multi-layer high-quality insulation material, including multi-layer mica board, multi-layer Ceramic fiberboard.

Formed insulation panels and shorting rings are placed on the top and bottom of the furnace.

The composite leak-proof detection is safe and reliable. When metal liquids invades or is about to penetrate the refractory material and the coil, it automatically cuts off the power and alarms. The composite leak proof probe is an important part of the overall leak protection system. At the same time, it also ensures that the molten iron is grounded to ensure the safety of the operator.

The bottom structure satisfies the requirement of removing the furnace lining by using the lining pushing mechanism. Easy to install and easy to operate.

Power Supply Unit

single output intermediate frequency power supply, all devices are installed in closed cabinet. The incoming line power supply is 380V ,660V or 1000V.

The frequency conversion power supply adopts the international advanced technical level control technology, all its components and components are all internationally renowned brands.

In copper output, in close proximity to the position of the coil arrangement of the earthing switch. When to carry out maintenance on the furnace body part, the side of the stove body and the copper coil on the short circuit, to ensure the personal safety of the operator.

Cabinet

In the cabinet all thyristors and diodes are TECHSEM brand products. Including rectifier and inverter.

The power cabinet is made of high strength cold rolled steel sheet, 2 mm thick. Can easily access the rectifier and inverter parts. The layout of power supply cabinet is reasonable, easy to maintain, line running and wiring specification (with drawings). The maintenance personnel can easily access all the maintenance points.

Power Supply Features

|

NO.

|

ITEM

|

SUPPLIERS AND MANUFACTURERS

|

|

1

|

Silicon controlled thyristor

|

TECH SEMICONDUCTORS

|

|

2

|

capacitors

|

Xadr Company WEIWEI Brand

|

|

3

|

Coil tube T2

|

Chinalco Luoyang Copper Co., Ltd

|

|

4

|

Copper bar T2

|

Chinalco Luoyang Copper Co., Ltd

|

|

5

|

Power cabinet main switch

|

Zhejiang TENGEN

|

1.

Advanced electronic circuit control, with over-voltage, over-current, limiting pressure, current limiting, lack of phase,

undervoltage, underwater pressure, phase sequence automatic identification, cooling water temperature alarm protection and many

other protection features. Power factor automatic adjustment function. From the cold charge to the heating temperature during the

cycle, automatically maintain full power to the furnace, so the maximum amount of

molten metal per kilowatt, the shortest same power heating time, increased labor productivity.

undervoltage, underwater pressure, phase sequence automatic identification, cooling water temperature alarm protection and many

other protection features. Power factor automatic adjustment function. From the cold charge to the heating temperature during the

cycle, automatically maintain full power to the furnace, so the maximum amount of

molten metal per kilowatt, the shortest same power heating time, increased labor productivity.

2.

Control line dedicated integrated box and high pressure area are fully isolated, keep the control room clean and cool. Greatly improve the control circuit board life and system reliability.

3.

High-power converter parts preferred from international and domestic well-known manufacturers, and parts design to run at 50%

rated capacity, so with 100% design safety factor, increase the overall system reliability.

rated capacity, so with 100% design safety factor, increase the overall system reliability.

4.

The equipment uses large cooling copper bars, the water-cooled copper, more energy for heating, increased efficiency, don't need maintenance.

5.

Power start using zero voltage sweep start, no impact, in the state of empty-load, heavy load, cold steel and others can be reliable start, stable, without breakdown for long time and facilitate to maintenance.

Detailed Images

Product Items:

|

1

|

one set

|

2000KW(One set), 500HZ output power supply cabinet

|

|

2

|

Two

|

Induction melting Furnace body with hydraulic tilting system

|

|

3

|

One set

|

Capacitor Assembly bank(Water cooling)

|

|

4

|

one set

|

Water cooled cables

|

|

5

|

one set

|

Technical documents, drawings and operation manuals

|

|

6

|

one set

|

Necessary spare parts for power supply cabinet

|

Packing&Shipping

The whole equipment finished full and completely covered by container to delivery. The equipment will fixed by our factory in container to prevent damaged by crash in the delivery process.

Small capacity furnace packaged by Plywood Case or as customers' request.

After Sales Service

Installation and commissioning:

We send engineers to guide equipment installation, and responsible for Commissioning, When training and installation

need pay wage to engineers.The user should first according to our foundation for the building, in accordance with the drawings and

use the instructions to install the furnace and prepare the power supply in place, water, circuit materials prepared completely.

need pay wage to engineers.The user should first according to our foundation for the building, in accordance with the drawings and

use the instructions to install the furnace and prepare the power supply in place, water, circuit materials prepared completely.

Hot Searches