The panel specification could be custom made as per different requirement. They could be transported, installed or uninstalled fast and easily. T panel, wall panel and L panel could be applied freely to reach a scientific design, simple and practical as well as cost saving purpose.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Feininger

-

Heat Conductivity:

-

0.02-0.030 W/m.K

-

Compression:

-

150-1000KPA

-

Color:

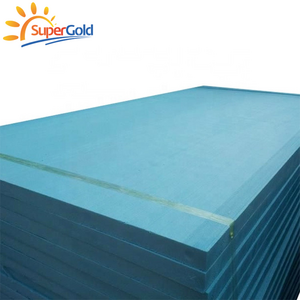

-

Yellow / Blue/ Pink

-

Water Absorption:

-

<=1.5%

-

Working Temperature:

-

-50--+75 Celsius

Quick Details

-

Project Solution Capability:

-

total solution for projects

-

Application:

-

Hotel

-

Design Style:

-

Modern

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Feininger

-

Heat Conductivity:

-

0.02-0.030 W/m.K

-

Compression:

-

150-1000KPA

-

Color:

-

Yellow / Blue/ Pink

-

Water Absorption:

-

<=1.5%

-

Working Temperature:

-

-50--+75 Celsius

Product Description

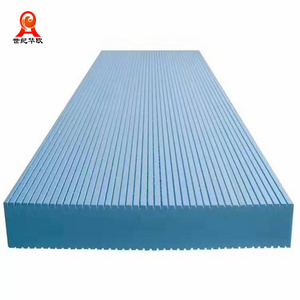

XPS Sandwich Boards

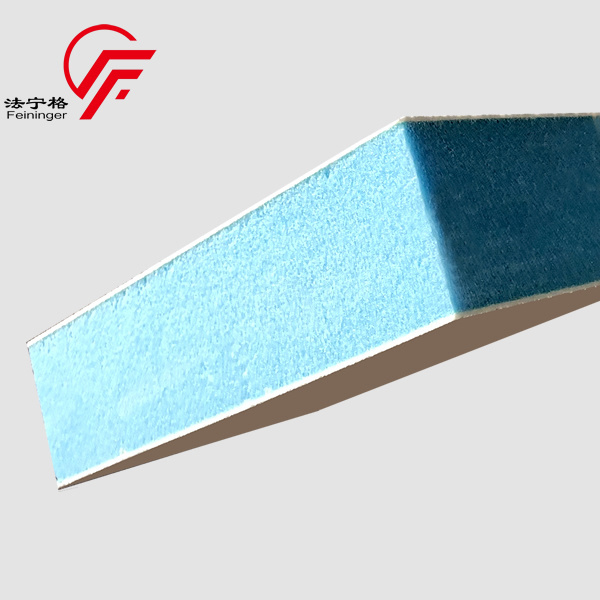

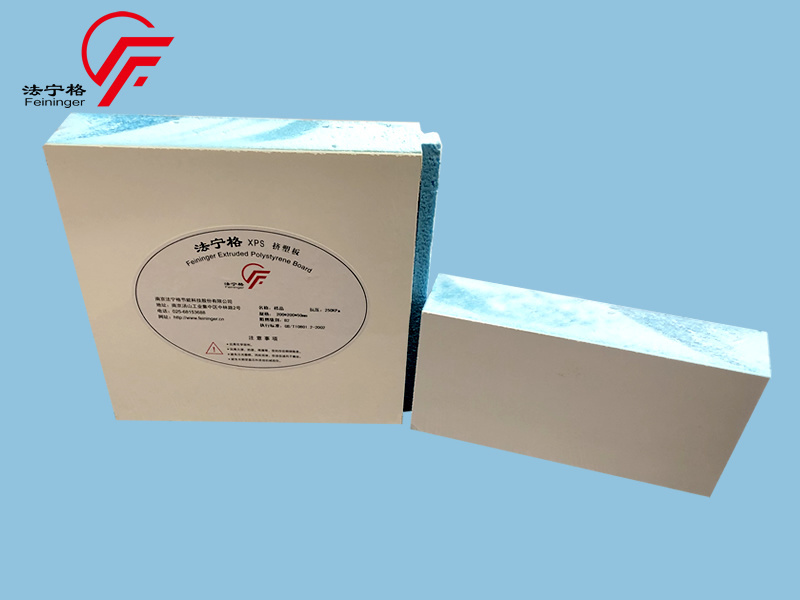

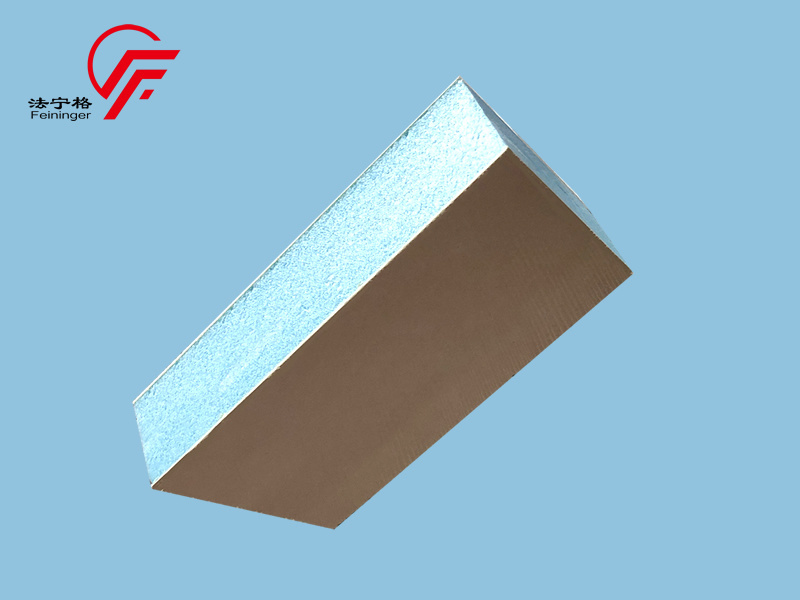

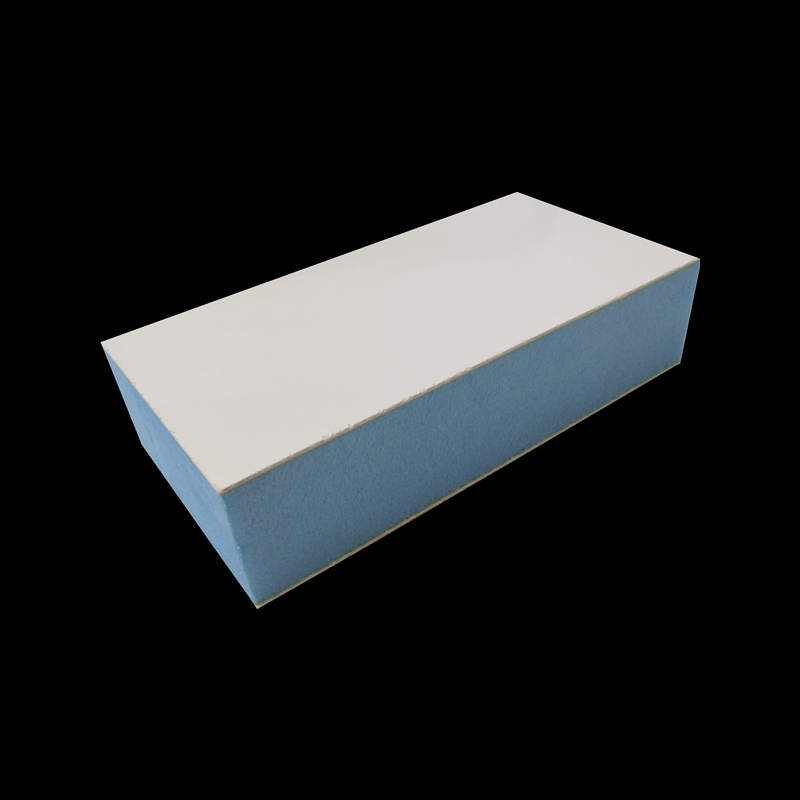

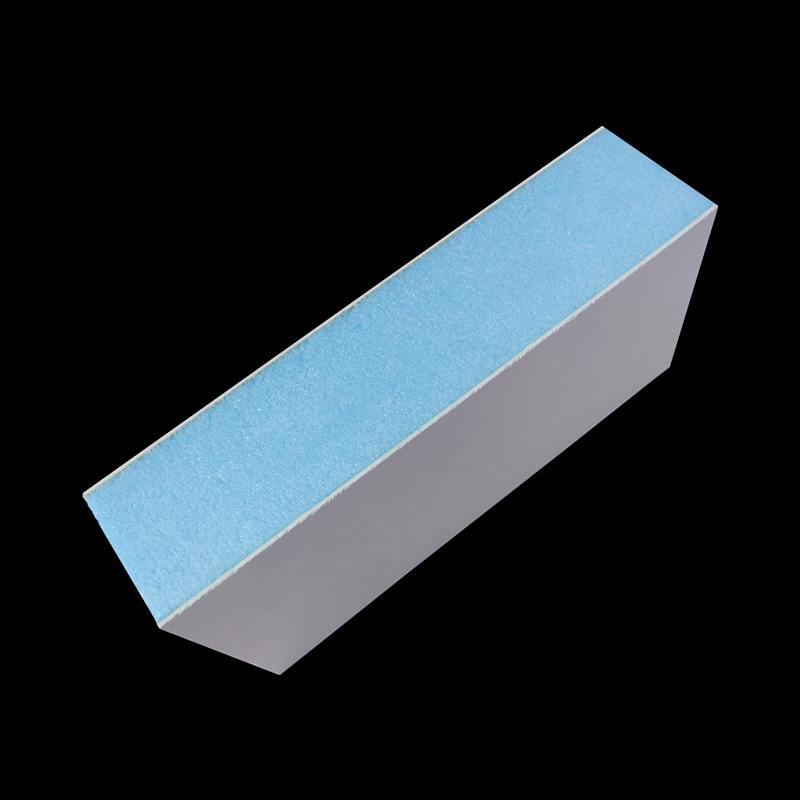

XPS Sandwich Panel is a kind of light weight energy saving wall material taking calcium sulfate board as face panel, xps (extruded polystyrene) as core and forming by one time compound.

Specification

|

Composition

|

Calcium sulfate board (face panel) + XPS (core) + Calcium sulfate board (face panel)

|

|

Size

|

Length: 1180-3000mm

Width: 600-1220mm Thickness: 60mm, 90mm, 120mm, 150mm, 180mm |

|

Usage

|

Interior and exterior partition on steel or concrete structure building, for new construction, additions or renovations.

|

|

Advantages

|

Light weight, sound insulation, heat insulation and preservation, water proof, fire proof, fast construction, save space and so

on... |

Characteristic

According to "Cold Storage Design Codes", insulation materials for cold storage shall meet the following requirements:

(1. Low thermal conductivity

(2. No toxic substances or smell pollution to food

(3. Flame retardant or non-inflammable, not easily deteriorat

(4. Temperature deformation of bulk materials should be small, easy to be cut at construction site, easy to be cut at construction

site, and easy to be bonded with base materials.

(5. The compressive strength of board for floor or roof deck insulation should not be less than 250KPa.

(1. Low thermal conductivity

(2. No toxic substances or smell pollution to food

(3. Flame retardant or non-inflammable, not easily deteriorat

(4. Temperature deformation of bulk materials should be small, easy to be cut at construction site, easy to be cut at construction

site, and easy to be bonded with base materials.

(5. The compressive strength of board for floor or roof deck insulation should not be less than 250KPa.

Our Advantages

25MM XPS=40MM EPS=200MM Aerated Concrete=620MM Solid Brick

Application

Hot Searches