- Product Details

- {{item.text}}

Quick Details

-

Colors:

-

Black or Yellow

-

Technique:

-

Forging casting

-

Surface Hardness:

-

HRC50-56,deepth:4mm-10mm

-

Warranty time:

-

2000 hours

-

Certification:

-

ISO9001-9002

-

FOB Price:

-

FOB Xiamen USD38-68/Pair

-

MOQ:

-

1000

-

Delivery time:

-

Within 30 days after contract established

-

After Warranty Service:

-

Video technical support

Quick Details

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

OEM

-

Material:

-

35MnB, 40Mn2

-

Colors:

-

Black or Yellow

-

Technique:

-

Forging casting

-

Surface Hardness:

-

HRC50-56,deepth:4mm-10mm

-

Warranty time:

-

2000 hours

-

Certification:

-

ISO9001-9002

-

FOB Price:

-

FOB Xiamen USD38-68/Pair

-

MOQ:

-

1000

-

Delivery time:

-

Within 30 days after contract established

-

After Warranty Service:

-

Video technical support

Products Description >>>

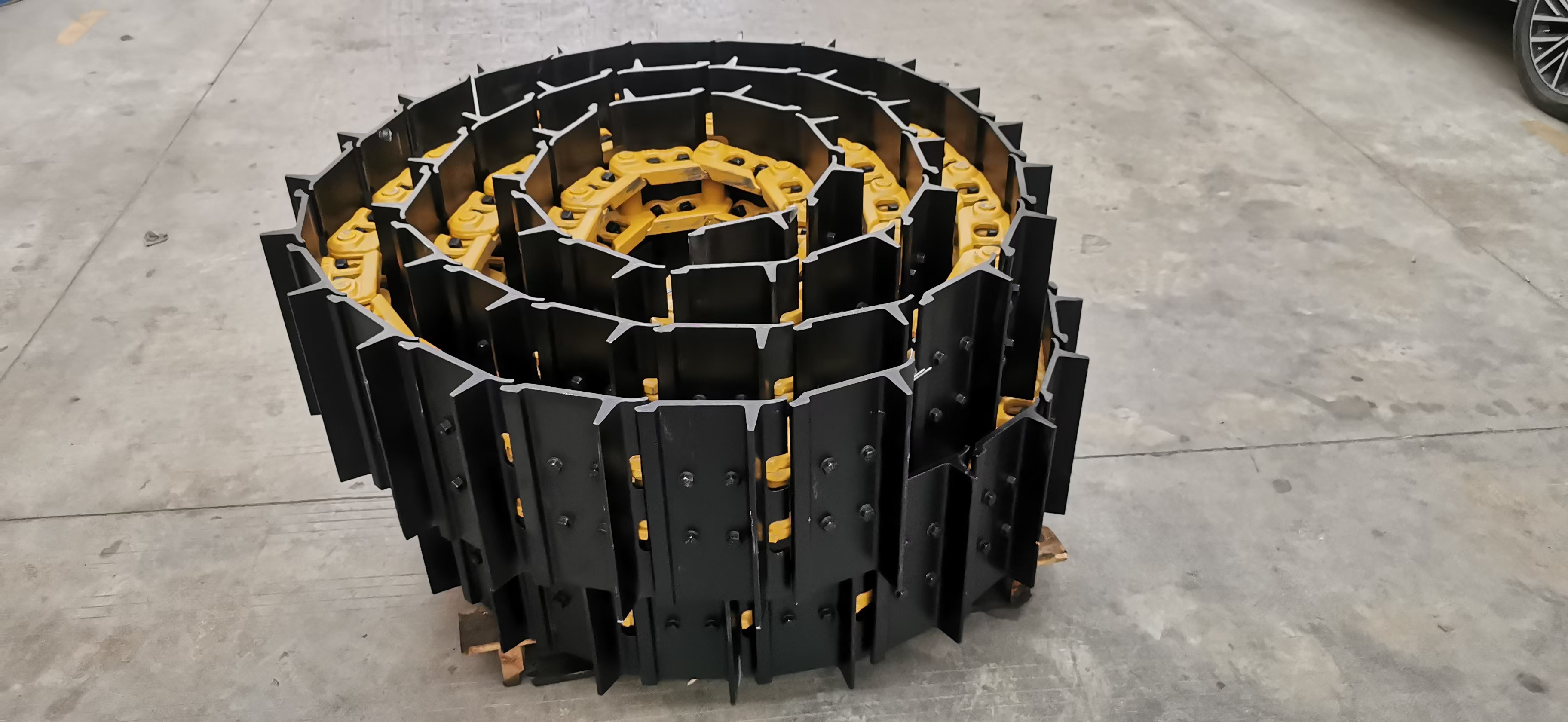

About our track chains

Our track link segments are forged with 35MnB special steel, reinforced structure technology and advanced tempering, annealing and hardening heat treatment processes to ensure the maximum strength and wear resistance of the products. There is also a self-supporting lubrication system, which can separate the sand and stone under working conditions, significantly improving the bearing life of the track link.

Routine Undercarriage Maintenance

When inspecting your equipment’s undercarriage, you are looking to see that everything is in its correct place and working properly. This includes things such as:

* Maintaining proper track tension. Refer to your manual on how tight your track should be and attempt to keep it there. Both loose and tight tracks can cause issues preventing your machine from functioning properly.

* Using appropriate track shoes for different job sites. Depending on the type of movement your machinery will be doing and the terrains you’ll be working in, choose track shoes that work well.

* Signs of significant wear on the idlers. Notable tread will appear as deep pockets or grooves across the surface of the idler. You also want to ensure that a lip has not formed on the edge of the idler. If so, this lip indicates that it may be time for servicing.

* Keeping your undercarriage clean and well-lubricated. Build-up of dust, mud, and debris can impact lubrication and make your equipment more difficult to use, which may cause operators to be a bit rougher when forcing it to maneuver or operate.

* Inspecting frequently. Frequent and thorough inspections, preferably with an operator’s manual in hand, can help operators spot wear, damage, and other issues before they get out of hand and result in more significant repair costs. These visual inspections should occur daily.

When inspecting your equipment’s undercarriage, you are looking to see that everything is in its correct place and working properly. This includes things such as:

* Maintaining proper track tension. Refer to your manual on how tight your track should be and attempt to keep it there. Both loose and tight tracks can cause issues preventing your machine from functioning properly.

* Using appropriate track shoes for different job sites. Depending on the type of movement your machinery will be doing and the terrains you’ll be working in, choose track shoes that work well.

* Signs of significant wear on the idlers. Notable tread will appear as deep pockets or grooves across the surface of the idler. You also want to ensure that a lip has not formed on the edge of the idler. If so, this lip indicates that it may be time for servicing.

* Keeping your undercarriage clean and well-lubricated. Build-up of dust, mud, and debris can impact lubrication and make your equipment more difficult to use, which may cause operators to be a bit rougher when forcing it to maneuver or operate.

* Inspecting frequently. Frequent and thorough inspections, preferably with an operator’s manual in hand, can help operators spot wear, damage, and other issues before they get out of hand and result in more significant repair costs. These visual inspections should occur daily.

|

Material

|

35MnB、40Mn2

|

|

Colors

|

Black or Yellow

|

|

Technique

|

Forging casting

|

|

Surface Hardness

|

HRC50-56,deepth:4mm-10mm

|

|

Warranty time

|

2000 hours

|

|

Certification

|

ISO9001-9002

|

|

FOB Price

|

FOB Xiamen USD38-68/Pair

|

|

MOQ

|

1000

|

|

Delivery time

|

Within 30 days after contract established

|

Application >>>

|

PC40,PC60-5-6-7,PC100,PC120,PC130,PC240,PC200-1-3-5-6,PC220-1-3-5,PC300-3-5,PC400-1-3-5,D20,D30,D31,D50,D60,D75,D80(D85),D155

|

|

Hitchi:

EX40,EX60,EX150,EX100M,EX100,EX120,EX150,EX200-1-2-3,EX300-1-3-5,EX400,UH08,UH07

|

|

E110B,E200B(E320),E240(MS180),E300B,E330.E3C,D5,D5B,D5D,D6C,D6D,D6H,D7G,D8K

|

|

Daewoo:

DH220,DH280,R200,R210

|

|

Kato:

HD250,HD400(HD450),HD500.HD550,HD700(HD770),HD800,HD820,HD850,DH880,HD1020,HD1220(HD1250),HD1430,DH1880

|

|

Kobelco:

SK07N2,SK07-7,SK200,SK220,SK300,SK320

|

|

Sumitomo:

SH120,SH160,SH200,SH220,SH280,SH300,SH400

|

|

Mitsubishi:

MS110,MS120,MS180

|

|

Samsung:

SE55,SE210

|

About Us >>>

Xi’An Yingming Machine Co.,Ltd.

is a company specialized in manufacturing and sales of the engineering machinery. The company has complete supply ability for engineering machine products. With more than 20 years professional innovation and manufacturing experiences, we can offer clients various engineering machine parts especially for undercarriage parts and ground engaging parts of excavator like track roller, Carrier roller, track link assy, sprocket and bucket for different excavator machine brand like KOMATSU, CAT, HITACHI, KOBELCO, SUMITOMO, KATO, HYUNDAI, DAEWOO . With high quality products, Price advantage and quality customer service, Yingming Machine Co., Ltd. consistently wins high comment and good reputation from a lot of clients from domestic and oversea market in the industry.

Factory Facility >>>

Quality Control >>>

Packing & Storage >>>

Delivery >>>

FAQ >>>

1. You are a trader or a manufacture?

We are an industry and trade integration business.

2. How can I be sure the part will fit my excavator?

Give us correct model number/machine serial number/ any numbers on the parts itself. Or measure the parts give us dimension or drawing.

3. How about the payment terms?

We usually accept T/T or Trade Assurance. other terms also could be negotiated.

4. What is your minimum order?

It depends on what you are buying. Normally, our minimum order is one 20’ full container and LCL container (less than a container load) can be acceptable.

5. What is your delivery time?

FOB any Chinese port : 20 days . If there are any parts in stock , our delivery time is only 0-7 days.

6. What about Quality Control?

We have a perfect QC system for the perfect products. A team who will detect the product quality and specification piece carefully, monitoring every production process until packing is complete, to ensure product safety into container.

Hot Searches