- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*150*200 mm, 400*200*200 mm

-

Place of Origin:

-

China

-

Brand Name:

-

LPMIE

-

Weight (KG):

-

800 kg

-

Raw material:

-

Cement, clay

-

Products:

-

Concrete Interlock Blocks

-

Brick type:

-

Hollow Brick Concrete Brick Hole Brick

-

Advantage:

-

Automatic Hydraulic Block Production Line

-

Weight:

-

8t

-

Keywords:

-

brick making machine

-

Application:

-

Buliding Construction

-

After-sales Service Provided:

-

Video technical support

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine, Other, Autoclaved aerated concrete block (AAC)

-

Brick Raw Material:

-

Cement

-

Production Capacity (Pieces/8 hours):

-

12000 pcs/8hours

-

Brick size:

-

400*100*200 mm, 400*150*200 mm, 400*200*200 mm

-

Place of Origin:

-

China

-

Brand Name:

-

LPMIE

-

Weight (KG):

-

800 kg

-

Raw material:

-

Cement, clay

-

Products:

-

Concrete Interlock Blocks

-

Brick type:

-

Hollow Brick Concrete Brick Hole Brick

-

Advantage:

-

Automatic Hydraulic Block Production Line

-

Weight:

-

8t

-

Keywords:

-

brick making machine

-

Application:

-

Buliding Construction

-

After-sales Service Provided:

-

Video technical support

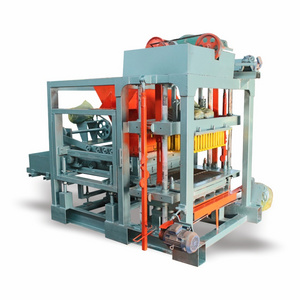

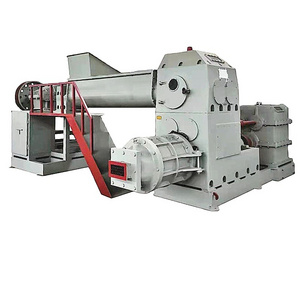

Application of automatic hydraulic burning free brick machine

The full-automatic hydraulic unburned brick machine is mainly used for pressing brick with fly ash, river sand, sea sand, mountain sand, mineral powder, slag, stone powder, coal slag, coal gangue, tailings slag, chemical slag as the main raw materials, adding a certain proportion of cement or lime and other cementitious materials. According to the different molds, it can be pressed into standard brick, perforated brick, blind hole brick, hollow brick, pavement brick and brick with special needs; according to the later curing process, it can be divided into natural curing unburned brick and autoclaved curing brick (autoclaved brick).

Configuration parameter

| Dimension of machine | 6500X1850X2650(L×W×H)(mm) |

| Pressure of hydraulic system | 21Mpa |

| Main vibration mode | Die compression and vibration |

| Vibration frequency | 50~70Hz |

| Suitable for brick height | 50-200mm |

| Pallet size | 900×810×20(mm) |

| Molding cycle | 12-15s |

| Total power | 35KW |

| Overall weight | 8t |

Main products

| Specification of brick |

Block 390X190X190 |

Block 390X100X190 |

Dutch brick 200X100X60 |

I-shaped brick 200X165X60 |

Wave brick 225X112.5X60 |

| Brick sample | |||||

| Pcs / mold | 6 | 12 | 20 | 12 | 15 |

| Pcs / hour | 1080 | 2160 | 2400 | 1440 | 1800 |

| Pcs / 8 hours | 8640 | 17280 | 19200 | 11520 | 14400 |

Packing:

Whole machine and every parts wrapped by plastic film for dusting-proof.

Packed in export standard wooden case with pallet, conducive to forklift handling.

Shipping:

Shipping method: by sea, by air, by international express company.

Delivery time: 30-45 days after order confirm.

Forwarder: We have shipping forwarder agent for sending the goods to all over the world, can arrange shippment to destination port and to door for customer. We also accept forwarder agent of customer.

Why choose us?

15 years gold supplier of Alibaba.

20 years experience of machinery.

Trade assurance member of Alibaba.

How long can we get the goods?

For standard machine, we usually delivery in two weeks.

Customized machine delivery in 30-60 days.

How should I do if meet some trouble while using?

We supply 24 hours online service.

What is your terms of payment?

100% Payment before shipment or as negotiated terms with clients.

Guarantee:

12 months for the whole machine. Within 12 months under normal use and maintenance, if something is wrong with the machine, you will get spare part for free. Out of 12 months, you will get spare parts at cost price. You will also get technical support and service all the lifetime.

Technical support:

1, Technical support by phone, email or MSN/Skype around the clock

2, Friendly English version manual and operation video CD disk

3, Engineer available to service machinery overseas

After sales services:

Normal machine is properly adjusted before dispatch. You will be able to use the mchines immediately.

You will be able to get free training advice towards our machine in our factory. You will also get free suggestion and consultation, technical support and service by email/fax/tel and lifetime technical support.