- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

4Kw

-

Dimension(L*W*H):

-

6500*3100*2600mm

-

Weight:

-

3500 kg

-

Product name:

-

Tissue paper machine

-

Finished Products:

-

roll Paper

-

Application:

-

paper Industry

-

Trimmed Width:

-

1880mm-3800mm

-

Grammage rang:

-

13~45GSM

-

Design Speed:

-

180-1200m/min

-

Working Speed:

-

150~1000m/min

-

Embossing unit:

-

Steel Embossing

-

Forming Type:

-

Reciprocating Forming

-

Type:

-

Paper Producton Line

Quick Details

-

Production Capacity:

-

200 m/min

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YG/OEM

-

Voltage:

-

380V

-

Power:

-

4Kw

-

Dimension(L*W*H):

-

6500*3100*2600mm

-

Weight:

-

3500 kg

-

Product name:

-

Tissue paper machine

-

Finished Products:

-

roll Paper

-

Application:

-

paper Industry

-

Trimmed Width:

-

1880mm-3800mm

-

Grammage rang:

-

13~45GSM

-

Design Speed:

-

180-1200m/min

-

Working Speed:

-

150~1000m/min

-

Embossing unit:

-

Steel Embossing

-

Forming Type:

-

Reciprocating Forming

-

Type:

-

Paper Producton Line

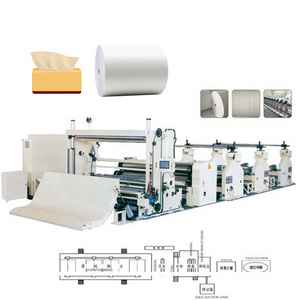

automatic n-fold tissue paper making machine rolled toilet paper machine made in germany

Product Description

The automatic toilet paper production line usually includes three equipments: automatic toilet paper rewinder, automatic paper cutter and automatic toilet paper packaging machine. The production efficiency of automatic toilet paper rewinder is higher than that of ordinary toilet paper rewinder. The roll function achieves the goal of not requiring manual paper breakage.

After rewinding a roll of paper, it can automatically rewind a roll, so that the produced long roll paper is transferred to the fully automatic paper cutter for automatic cutting. Accurate cutting action, smooth cut surface of roll paper.

Specification

Part 1: Rewinder machine main features:

1.Using advanced PLC programming technology, the finished product realizes multi-level different tightness during the rewinding process, which solves the problem of the paper core loosening due to long-term storage of the finished product;

2.Three-layer horizontal paper unwinding rack, pneumatic paper feeding, pneumatic wide belt paper feeding,each roll of raw paper has an independent tension adjustment device;

3.Automatic trimming, glue spraying, and sealing are completed at one time. This device replaces traditional waterline trimming and realizes the popular foreign trimming and tailing technology, reducing the loss of paper tails during the production of ordinary rewinders, thereby reducing product cost.

Part 2 Automatic Band Saw Paper Cutting Machine Performance and characteristics:

◆ The LCD touch screen is used for humanized operation of the system, the calculator calculates and debugs, the setting is simple, and the man-machine dialogue is realized;

◆Equipped with an automatic knife sharpening system, the screen controls the feed, and the paper cutting process is very safe,without the need to employ personnel, which greatly reduces the insecurity index that occurred in the past, thereby improving the operator's sense of safety index;

◆The model is suitable for cutting roll paper with or without heart;

◆To change the specifications, only the required number of slits and slit length are set on the touch screen, and the size of the head and tail material can be flexibly set;

◆ The whole machine has advanced settings and stable performance. It adopts a unified series of

electrical component control, PLC

electrical component control, PLC

Part 3 Automatic sorting round roll middle packing machine performance and characteristics:

This machine is used for eight, ten,and twelve rolls of flat roll paper bagging and sealing semi-automatic packaging machine, directly connected to the paper cutter automatic material sorting after manual bagging, automatic sealing, cutting and blowing waste; Using PLC computer programming control, LCD text display parameters, can set the parameters of the whole machine system, realize the man-machine dialogue, the control is more precise; This machine is operated by one person, changing the traditional manual placing and unwinding of flat rolls, reducing the manufacturing cost and management cost of the enterprise;

The whole machine has reasonable structure, stable performance, solid materials, constant temperature heating sealing, and the sealing effect is stable and beautiful; Induction first and then work, making workers feel safer in use;

The same machine can pack products of various specifications. program control, frequency converter speed regulation, and servo motor drive, which is durable;

Packing & Delivery

Hot Searches